Casing repair material with high adhesion to metal and preparation method thereof

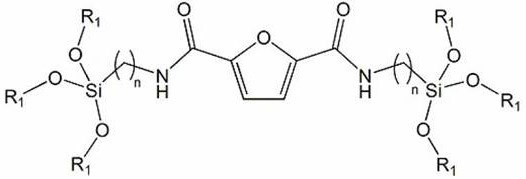

A repair material and high-adhesion technology, applied in the fields of functional polymers and oilfield chemicals, can solve the problems of insufficient adhesion of metal oil casings, poor compatibility between coupling agents and furan resins, etc. To achieve good effect, improve the repair effect, enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

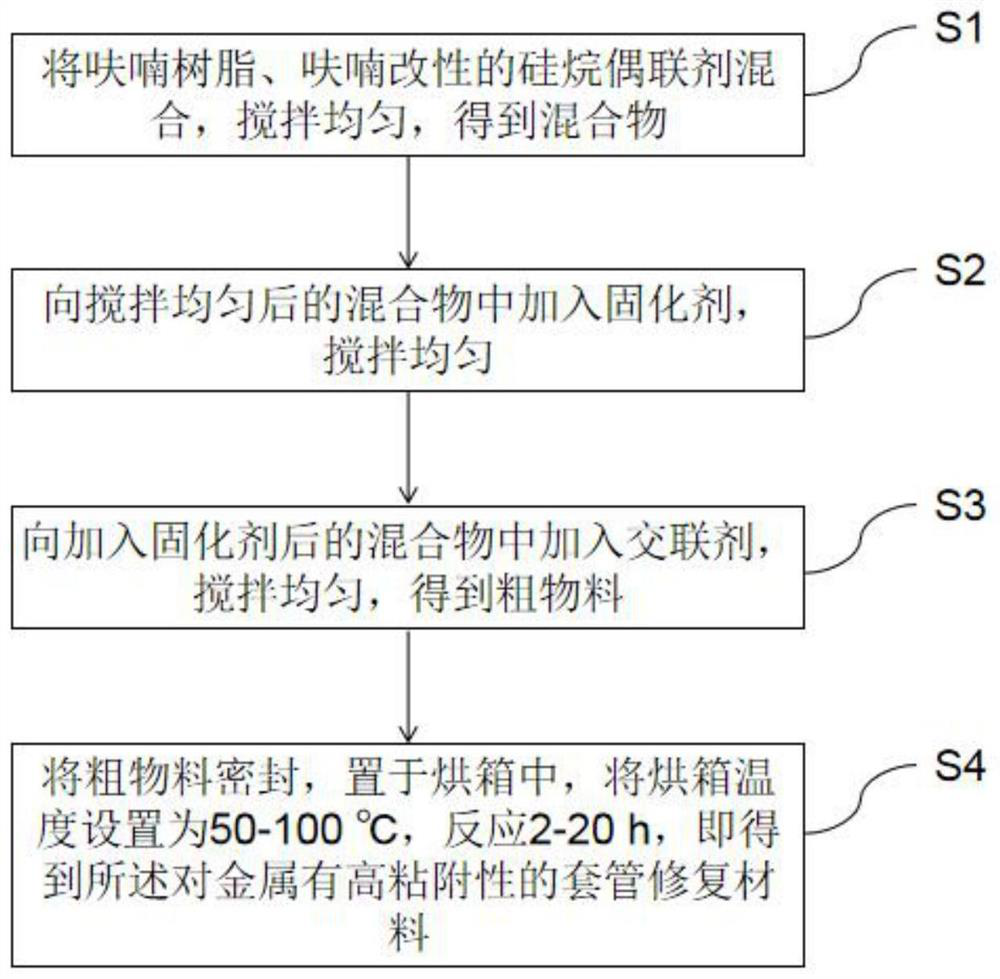

[0045] Please refer to the attached figure 1 ,Such as figure 1 As shown, the technical solution of the present application also provides a method for preparing a sleeve repair material with high adhesion to metal, comprising the following steps:

[0046] S1: Mix the furan resin and the furan-modified silane coupling agent, and stir evenly to obtain a mixture;

[0047] S2: Add curing agent to the mixture after stirring evenly, and stir evenly;

[0048] S3: adding a crosslinking agent to the mixture after adding the curing agent, stirring evenly to obtain a coarse material;

[0049] S4: Seal the crude material, place it in an oven, set the temperature of the oven at 50-100° C., and react for 2-20 hours to obtain the casing repair material with high adhesion to metal.

Embodiment 1

[0052] A casing repair material with high adhesion to metal, comprising the following raw materials in parts by weight:

[0053]

[0054] and prepared by:

[0055] (1) mixing furfuryl alcohol furan resin and furan modified silane coupling agent, stirring evenly to obtain a mixture;

[0056] (2) add ethyl sulfate in the mixture after stirring, stir;

[0057] (3) Add tetrakis (3-mercaptopropionic acid) pentaerythritol ester to the mixture after adding the curing agent, stir evenly to obtain a coarse material;

[0058] (4) Seal the crude material, put it in an oven, set the temperature of the oven to 80° C., and react for 12 hours to obtain the casing repair material with high adhesion to metal.

Embodiment 2

[0060] A casing repair material with high adhesion to metal, comprising the following raw materials in parts by weight:

[0061]

[0062] and prepared by:

[0063] (1) mixing furfuryl alcohol furan resin and furan modified silane coupling agent, stirring evenly to obtain a mixture;

[0064] (2) add benzenesulfonyl chloride in the mixture after stirring, stir;

[0065] (3) Add trimethylolpropane tris(3-mercaptopropionate) to the mixture after adding the curing agent, and stir evenly to obtain a coarse material;

[0066] (4) Seal the crude material, put it in an oven, set the temperature of the oven to 80° C., and react for 12 hours to obtain the casing repair material with high adhesion to metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com