Non-asphalt-based on-site coiled material and preparation method thereof

A non-bitumen-based, coiled material technology, which is applied in coatings, fiber types, textiles and papermaking, etc., can solve the problems of inconvenient use, slow drying speed, low temperature of coiled materials, etc., to reduce labor costs, short curing time, and anti-corrosion Good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

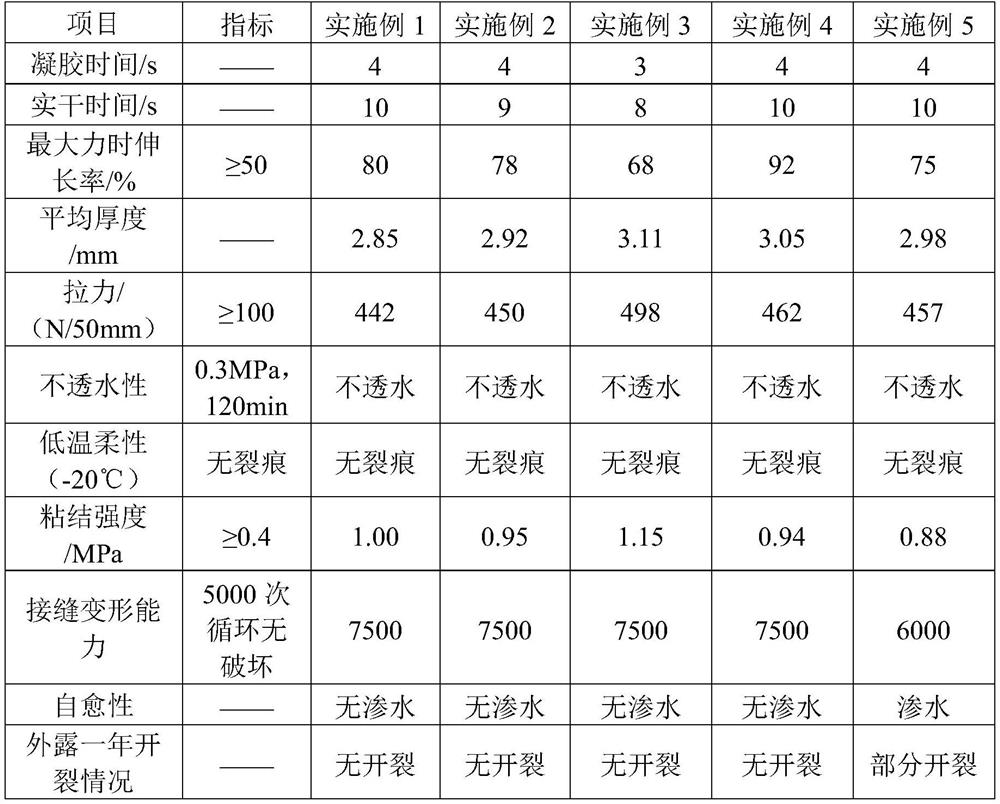

Examples

Embodiment 1

[0030] A non-asphalt-based ready-made coil material has a three-layer structure, from bottom to top, the first waterproof coating, the reinforced carcass layer, and the second waterproof coating, the first waterproof coating and the second waterproof coating are acrylate spray Membrane material, reinforced carcass layer is a carcass formed by fully soaking non-woven fabric in liquid superabsorbent resin and then drying.

[0031] The raw material of the acrylate spray film material is composed of A component and B component. The A component includes the following raw materials in parts by weight: 72 parts of magnesium acrylate aqueous solution with a concentration of 40% by mass, 4 parts of magnesium hydroxide, 15 parts of 3000 mesh light calcium carbonate 1 part, 5 parts of 1200 mesh heavy calcium carbonate, 1 part of dispersant, 0.5 part of wetting agent, 1 part of defoamer, 0.5 part of preservative, 1 part of organic bentonite; B component includes the following raw materials...

Embodiment 2

[0040]A non-asphalt-based ready-made coiled material has a three-layer structure, from bottom to top, the first waterproof coating, the reinforced carcass layer, and the second waterproof coating. The first waterproof coating and the second waterproof coating are acrylate spray coatings. Membrane material, reinforced carcass layer is a carcass formed by fully soaking non-woven fabric in liquid superabsorbent resin and then drying.

[0041] The raw material of the acrylate spray film material is composed of A component and B component, and the A component includes the following raw materials in parts by weight: 76 parts of magnesium acrylate aqueous solution with a mass percentage concentration of 40%, 6 parts of magnesium chloride, 12 parts of 3000 mesh light calcium carbonate, 3 parts of titanium dioxide, 0.5 part of dispersant, 0.5 part of wetting agent, 0.5 part of defoamer, 0.5 part of preservative, 1 part of organic bentonite; component B includes the following raw materia...

Embodiment 3

[0046] A non-asphalt-based ready-made coil material has a three-layer structure, from bottom to top, the first waterproof coating, the reinforced carcass layer, and the second waterproof coating, the first waterproof coating and the second waterproof coating are acrylate spray Membrane material, reinforced carcass layer is a carcass made of polypropylene cloth fully soaked in liquid superabsorbent resin and then dried.

[0047] The raw material of the acrylate spray film material is composed of A component and B component, and the A component includes the following raw materials in parts by weight: 80 parts of calcium acrylate aqueous solution with a concentration of 45% by mass, 8 parts of magnesium hydroxide, 6 parts of 1200 mesh heavy calcium carbonate 1 part, 2 parts of quartz powder, 1 part of dispersant, 0.5 part of wetting agent, 1 part of defoamer, 0.5 part of preservative, 0.5 part of fumed silica, 0.5 part of organic bentonite; B component includes the following raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com