Enzyme-microbe coupled fracturing fluid system and preparation method and applications thereof

A technology for microorganisms and fracturing fluid, applied in the field of water-based fracturing fluid system and its preparation, can solve the problems of affecting fracturing stimulation, large damage to formation original microorganisms, easy formation of filter cakes, etc., so as to improve fracture conductivity, The gel breaking time is controllable and the effect of promoting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A new water-based fracturing fluid for oil and gas extraction was created by:

[0031] 1) Weigh 0.45 g of vegetable gum polymer according to the weight ratio, and add it into 100 mL of water at a uniform speed under the condition of high-speed stirring to prepare guar gum base liquid.

[0032] 2) Add 0.02g of biological fungicide, 0.025g of biological drainage aid, 0.05g of preflush biooptimizer, 0.1g of microbial enhanced production increase agent, 2g of clay stabilizer, and 30mg / L of biological enzyme gel breaker.

[0033] 3) Adding a pH regulator to adjust the pH value to 8.5-9.5.

[0034] 4) Adding a cross-linking agent for cross-linking, the cross-linking agent is 1.5wt% borax aqueous solution, the addition amount is 5mL, and stirring gently at the same time, the jelly for fracturing can be obtained.

[0035] A preparation method of a pre-fluid bio-optimizer, whose function is to activate the original microorganisms of the oil well and provide a nutrient source fo...

Embodiment 2

[0047] Reagent preparation is as described in embodiment 1, construction scheme:

[0048] 1. Configure guar gum base liquid 40m according to the above formula 3

[0049] 2. Mix the sand in the sand mixer, and slowly add the gel breaker at the same time, the dosage is about 2kg / well. After cross-linking, pump it into the well with a pump truck.

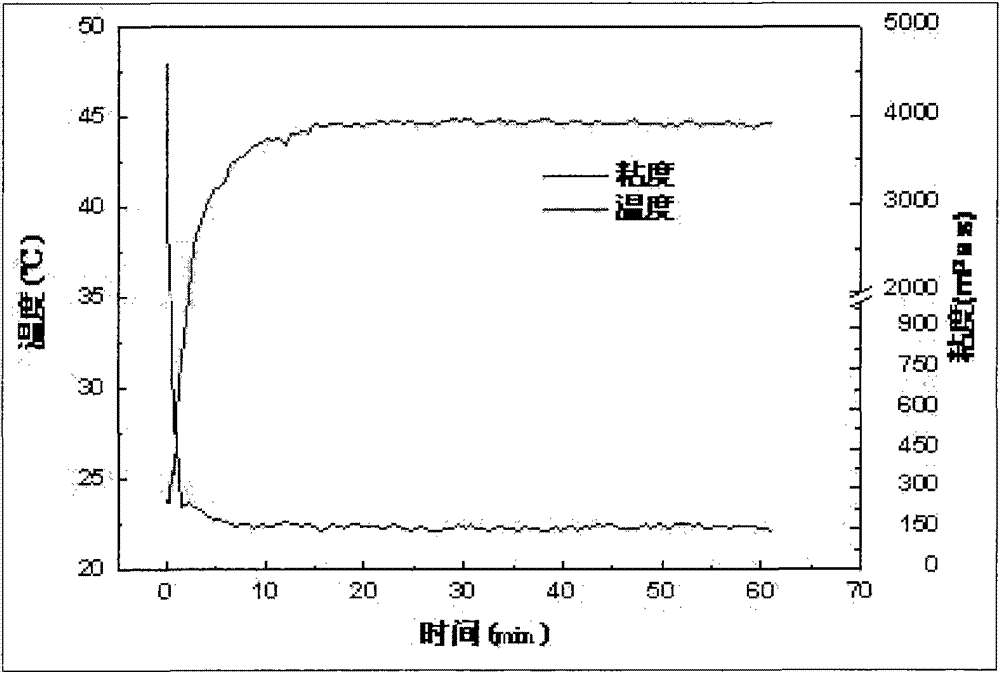

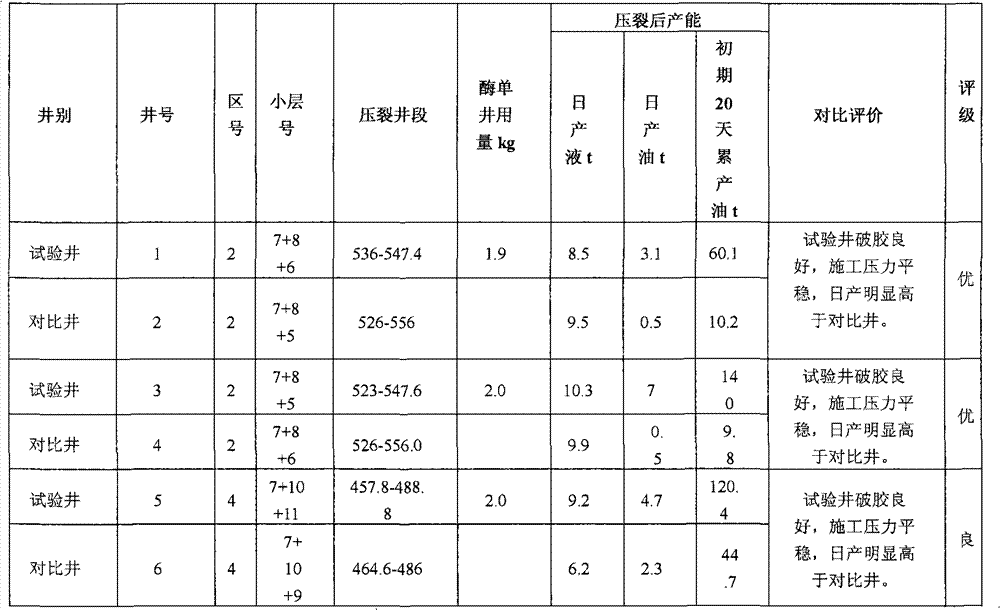

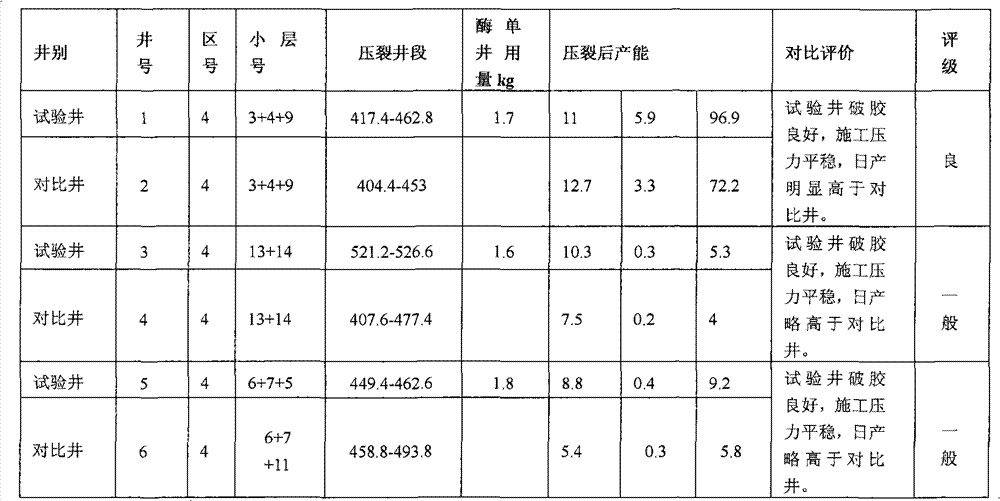

[0050] 3. The flowback of the gel breaking fluid is delayed for 2-3 hours, and the construction results are as follows:

[0051]

[0052] According to the above experimental data, the daily oil production of wells adopting the enzyme-microbial coupling fracturing system of the present invention is significantly increased in the case of delayed flowback after gel breaking. It can be seen that the use scheme of this invention can increase the oil production by half .

Embodiment 3

[0054] To reduce the amount of residue, use a core permeability tester, a core porosity tester, a core vacuum pressure saturation device, etc. to do the following tests. Reagent preparation is as described in embodiment 1, selects three rock cores of the same formation, and the initial data of rock cores are as follows:

[0055] Core physical parameter table

[0056]

[0057] The gel-breaking fluid that passes through the 1# core uses ammonium persulfate as the gel-breaking agent, the gel-breaking fluid that passes through the 2# core uses only biological enzymes as the gel-breaking agent, and the gel-breaking fluid that passes through the 3# core uses an enzyme-microbial couple The joint system is a gel breaker. The core damage is determined by instrumentation. The experimental procedure is as follows:

[0058] 1. The core is injected with kerosene until saturated. Inlet pressure is maintained at About 20MPa , the outlet pressure is maintained at About 0.2MPa . De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com