A temperature-responsive self-degrading temporary plugging agent and workover method

A temperature-responsive, self-degrading technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as complex processes, large rubber plugs, and complex and tedious construction processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] First, take by weighing 5g of acrylamide, 0.3g of polyethylene glycol 600 diacrylate, 0.5g of ammonium persulfate, and 0.25g of AMP-95 in 93.95mL of water to prepare a temperature-responsive self-degradation temporary plugging agent; The polyacrylamide aqueous solution with a mass fraction of 3‰ was used as pre-fluid and post-fluid.

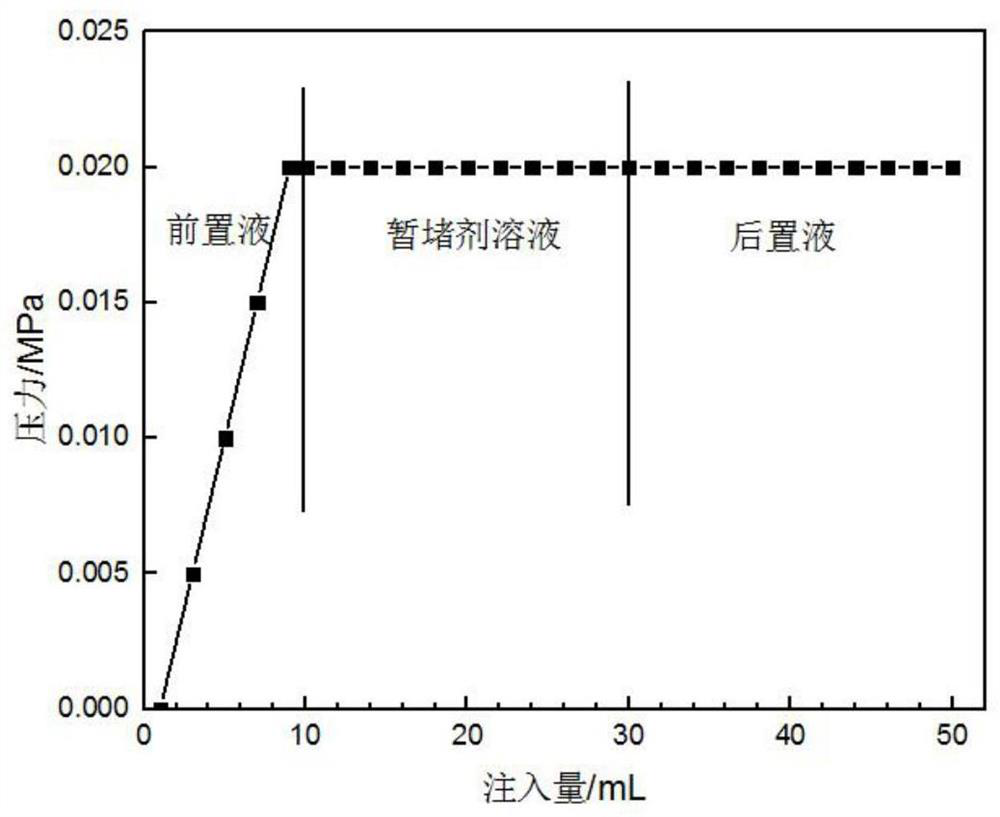

[0046] Inject 10mL of 3‰ polyacrylamide aqueous solution and 20mL temperature-responsive self-degrading temporary plugging agent in sequence into the 2000mD permeability core (simulated oil and gas well), and inject 20mL of 3‰ polyacrylamide aqueous solution after the gel is broken and observe the injection pressure in real time Then put the cores into 50℃, 60℃, 70℃, and 80℃ constant temperature ovens to test the temperature resistance of the temporary plugging agent. The experimental results are as follows figure 1 As shown, the influence of temperature on the gelation time and gel breaking time of the temperature-responsive self-degradin...

Embodiment 2

[0050] First weigh 4g of acrylamide, 0.1g of polyethylene glycol 600 diacrylate, 0.2g of ammonium persulfate, and 0.25g of AMP-95 in 95.45mL of water to prepare a temporary plugging agent solution; Aqueous acrylamide solution was used as pre-fluid and post-fluid.

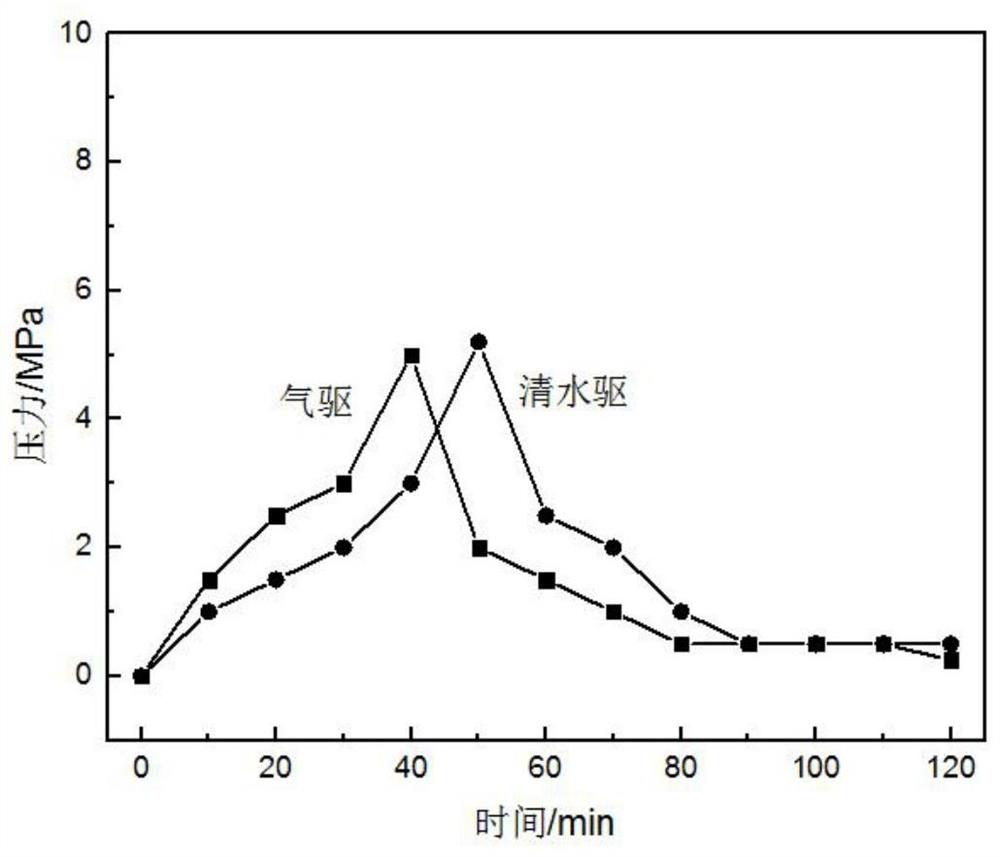

[0051] Inject 10mL of 4‰ polyacrylamide aqueous solution, 20mL of temperature-responsive self-degrading temporary plugging agent, and 20mL of 4‰ polyacrylamide aqueous solution into the 2000mD permeability core (simulated oil and gas well), and react in a constant temperature oven at 60°C for 4 hours After gelation, the core was taken out and used in the displacement device to test the breakthrough pressure of the temporary plugging agent by water flooding and gas flooding reverse displacement respectively. The experimental results are as follows: figure 2 As shown, it can be seen from the experimental results that the breakthrough pressure of the temporary plugging agent is up to 5MPa and 5.5MPa when the core is r...

Embodiment 3

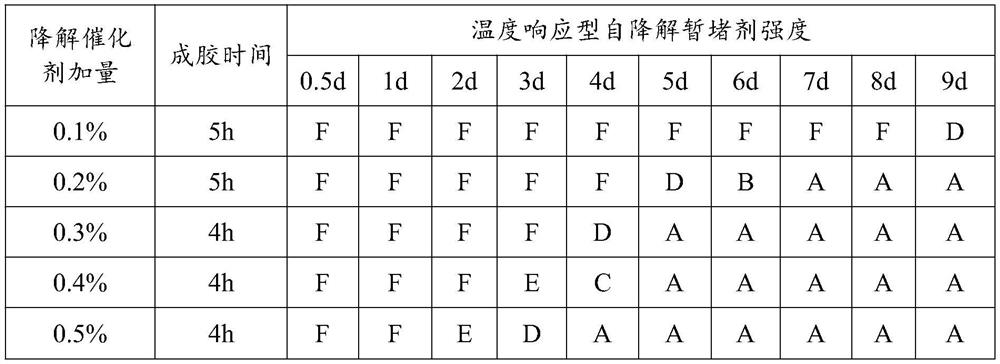

[0053] First, weigh 4g of acrylamide, 0.8g of polyethylene glycol 600 diacrylate, 1g of ammonium persulfate, respectively 0.1g, 0.2g, 0.3g, 0.4g, 0.5g of AMP-95 in water to prepare temporary plugging The mass fraction of acrylamide in the temporary plugging agent solution is 4%, the mass fraction of polyethylene glycol 600 diacrylate is 0.8%, the mass fraction of ammonium persulfate is 1%, and the mass fraction of AMP-95 is respectively 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, to test the effect of different degradation catalyst additions on the gel breaking time of the temperature-responsive self-degrading temporary plugging agent, and use the visual method to check the gel breaking time of the temporary plugging agent. Observation records, using the gel strength code method to represent the strength change of the gel temporary plugging agent, the experimental results are shown in Table 2. From the experimental results, it can be known that the composition of the temperature-responsive s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com