Quantum dot purification method

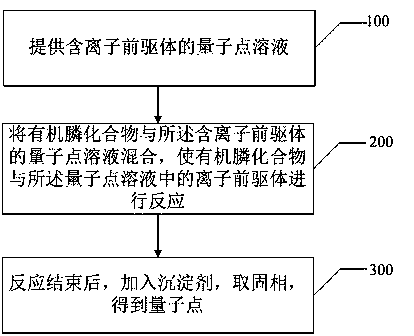

A purification method and technology for quantum dots, applied in the field of quantum dots, can solve the problem of inability to effectively separate quantum dot products from system impurities, and achieve the effects of easy repeatability and simple purification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this example, trioctylphosphine (TOP) was used to purify the quantum dot reaction system containing excess zinc oleate cation precursor, including the following steps:

[0062] (1) Provide 20mL of quantum dot reaction system containing excess zinc oleate cationic precursor after the reaction, and control the temperature from 300°C to 150°C;

[0063] (2) Add 2 mL of trioctylphosphine to the reaction system, and keep the temperature at 150°C for 15 minutes;

[0064] (3) Cool the reaction system to room temperature, then add acetone to obtain a precipitate, then centrifuge, discard the liquid phase, and redisperse the solid phase obtained by centrifugation in n-hexane, then add acetone to re-precipitate and centrifuge, and repeat this process for 5 times. Obtain high-purity quantum dot samples.

Embodiment 2

[0066] This embodiment uses octadecyl phosphonic acid to purify the quantum dot solution containing excess zinc oleate cationic precursor, including the following steps:

[0067] (1) Under the protection of an inert atmosphere, take 15 mL of n-hexane solution of quantum dots containing excess zinc oleate cation precursor, and inject it into a three-necked flask containing 15 mL of octadecene;

[0068] (2) Heat the solution system in the three-necked flask to 80°C and maintain it for 30mins to completely remove n-hexane in the solution system; continue to heat the solution system to 320°C, add 10mL of octadecylphosphonic acid to the solution system, and keep The temperature is 320°C for 1mins;

[0069] (3) After cooling the reaction system to room temperature, add acetone to obtain a precipitate, then centrifuge, discard the liquid phase, and then redisperse the solid phase obtained by centrifugation in n-hexane, then add acetone to re-precipitate and centrifuge, and repeat thi...

Embodiment 3

[0071] This embodiment uses tributylphosphine to purify the quantum dot reaction system containing excess Se-TOP anion precursor, including the following steps:

[0072] (1) Provide 20mL of quantum dot reaction system containing excess Se-TOP anion precursor after the reaction, and control the temperature from 300°C to 150°C;

[0073] (2) Add 0.2 mL of tributylphosphine to the reaction system, and stir for 12 hours at room temperature under nitrogen atmosphere;

[0074] (3) After cooling the reaction system to room temperature, carry out conventional precipitation and centrifugation purification: add acetone to obtain precipitation and then centrifuge, pour off the liquid phase, redisperse the solid phase obtained by centrifugation in n-hexane, then add acetone to re-precipitate and centrifuge, By repeating this process 5 times, a high-purity quantum dot sample can be obtained.

[0075] In summary, the present invention provides a method for purifying quantum dots. By adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com