Ester-producing yeast ZB406 and application thereof

A technology of yeast and Saccharomyces cerevisiae, which is applied to microorganisms, vinegar preparation, fungi and other directions, can solve the problems of rebirth, large differences, poor coordination, etc. Ester powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

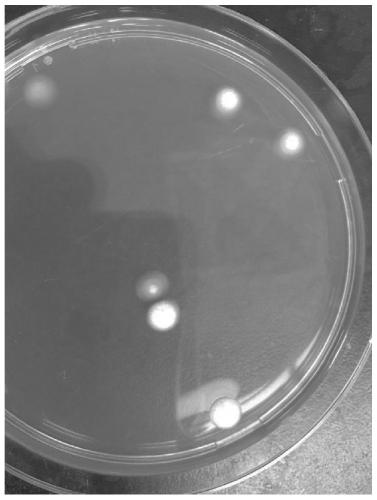

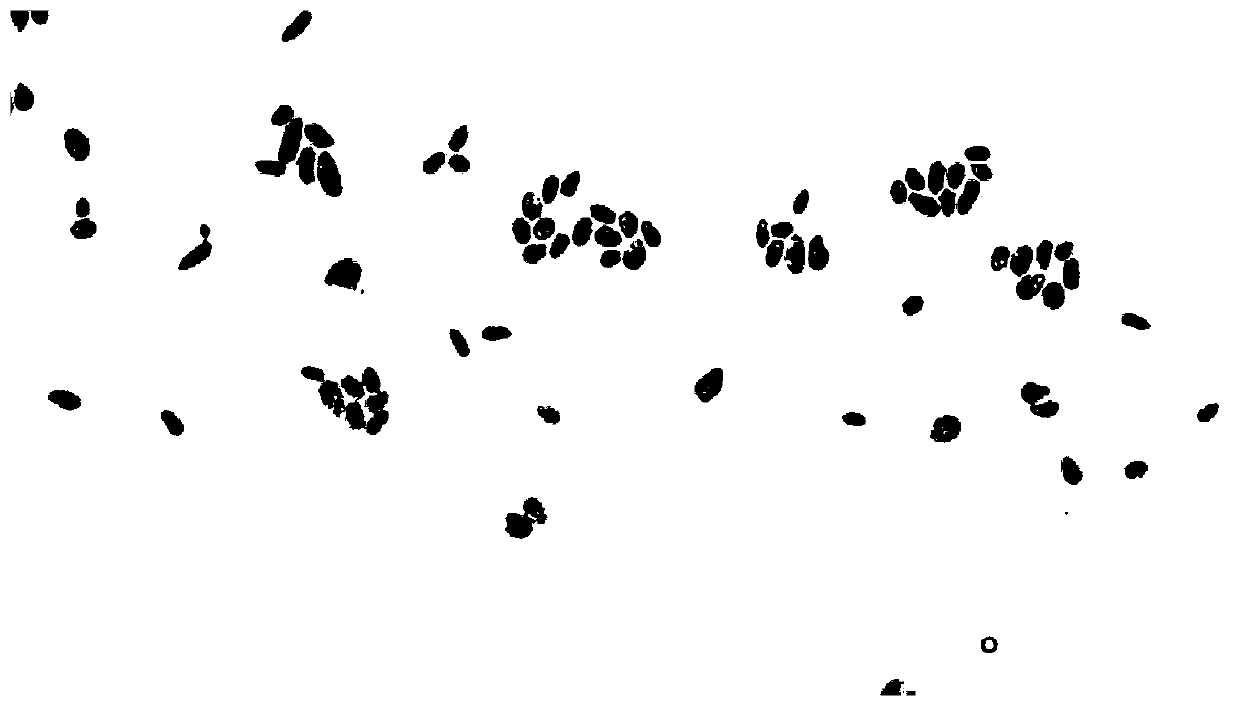

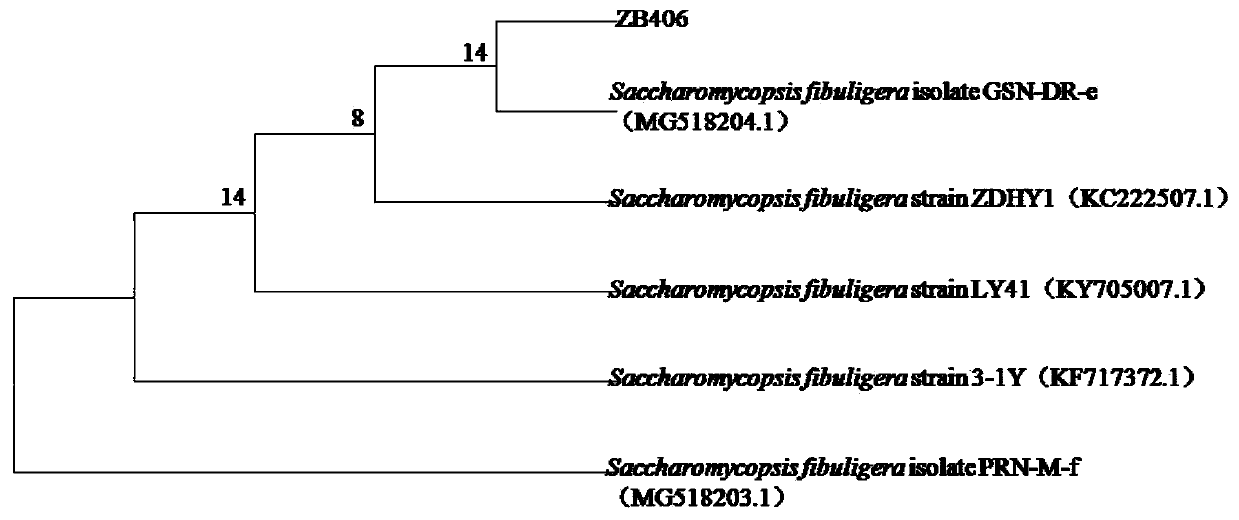

[0036] Example 1 Screening of ester-producing yeast strains

[0037] 1. Material preparation

[0038] Source of strain isolation: distiller's yeast collected by the applicant;

[0039] Saccharomyces rouxii AS 2.180: purchased from China Industrial Microbiology Culture Collection Management Center;

[0040] Wort medium, PDA medium, liquefaction enzyme, glucoamylase: commercially available;

[0041] Rice solid medium: take an appropriate amount of commercially available rice, add 1 to 2 times the weight of water, and autoclave at 121°C for 15 minutes.

[0042] Rice mash: take an appropriate amount of commercially available rice, add appropriate amount of tap water to cook, add liquefaction enzyme and glucoamylase during the cooking process to decompose starchy raw materials, and obtain rice mash.

[0043] 2. Isolation and screening of ester-producing yeast

[0044] 2.1 Strain isolation

[0045] Take 10 g of distiller's yeast and add it into 100 mL of wort medium, and enri...

Embodiment 2ZB406

[0058] Embodiment 2 ZB406 bacterial strain genetic stability evaluation

[0059] Inoculate the rice mash with ZB405 yeast obtained in Example 1, let it ferment at 30°C for 48 hours, take the fermented liquid and inoculate it with new rice mash, let it ferment at 30°C for 48 hours, and so on to obtain fermented liquids of different generations, and test the fermented liquid The content of ethyl acetate in the medium, the specific results are shown in Table 2.

[0060] Table 2 Evaluation results of genetic stability of strain ZB406

[0061] index 1st generation 5th generation 10th generation Ethyl acetate (g / 100mL) 0.71 0.72 0.70

[0062] From the test results shown in Table 2, the ethyl acetate-producing ability of the 1st generation, 5th generation, and 10th generation strains was stable. This shows that the esterogenic yeast ZB406 has good genetic stability and is very suitable for industrial production.

Embodiment 3

[0063] Example 3 Co-fermentation of ester-producing yeast and Saccharomyces cerevisiae

[0064] 1. Preparation of rice saccharification solution

[0065] Using commercially available rice as raw material, add 3-4 times the weight of tap water, heat up to 60-70°C, add 0.1-0.3% commercially available liquefaction enzyme for liquefaction and hydrolysis, keep warm at 90-95°C for 1 hour, and test the iodine solution to determine the end point of liquefaction. The obtained saccharified solution is used for later use.

[0066] 2. Rice Wine Preparation

[0067] Using rice saccharification liquid as raw material, ester-producing yeast strain ZB406 was activated with wort medium, and added simultaneously or step by step with S. The added amount is 0.3-0.5% of the weight of the rice raw material, the alcohol is fermented at 30 DEG C for 8-10 days, and the fermented rice wine is obtained by pressing the wine mash. The rice wine with different crafts was sent to ethyl acetate for insp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com