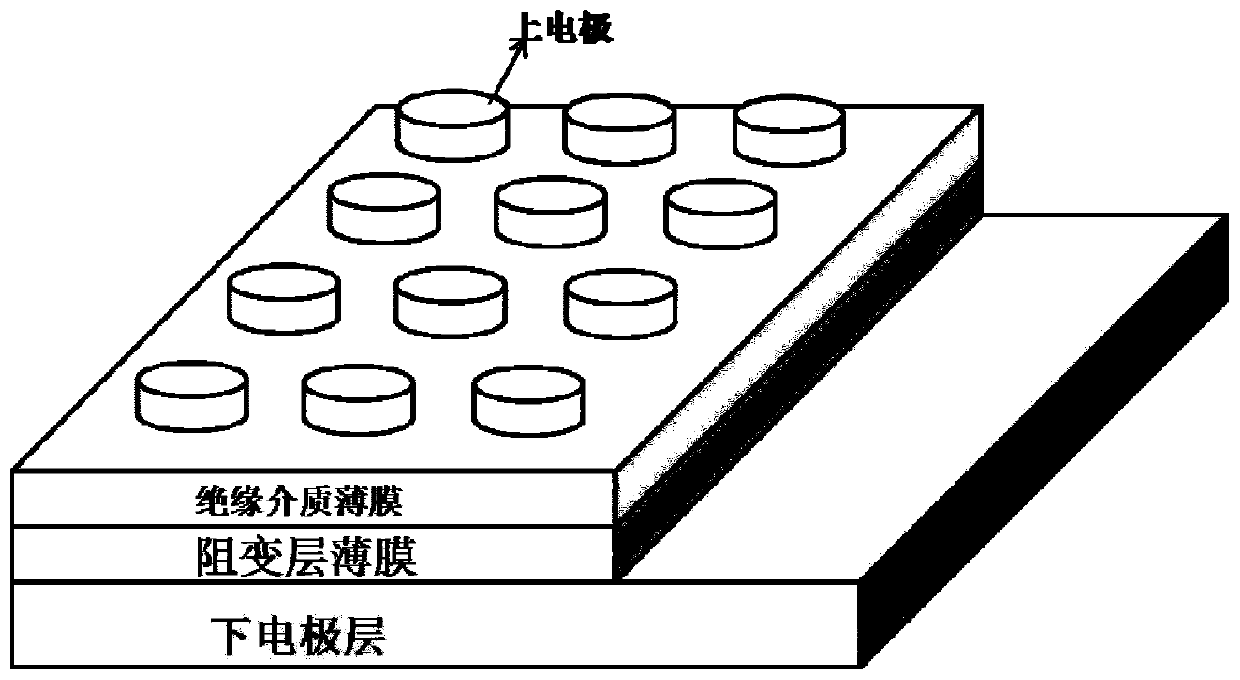

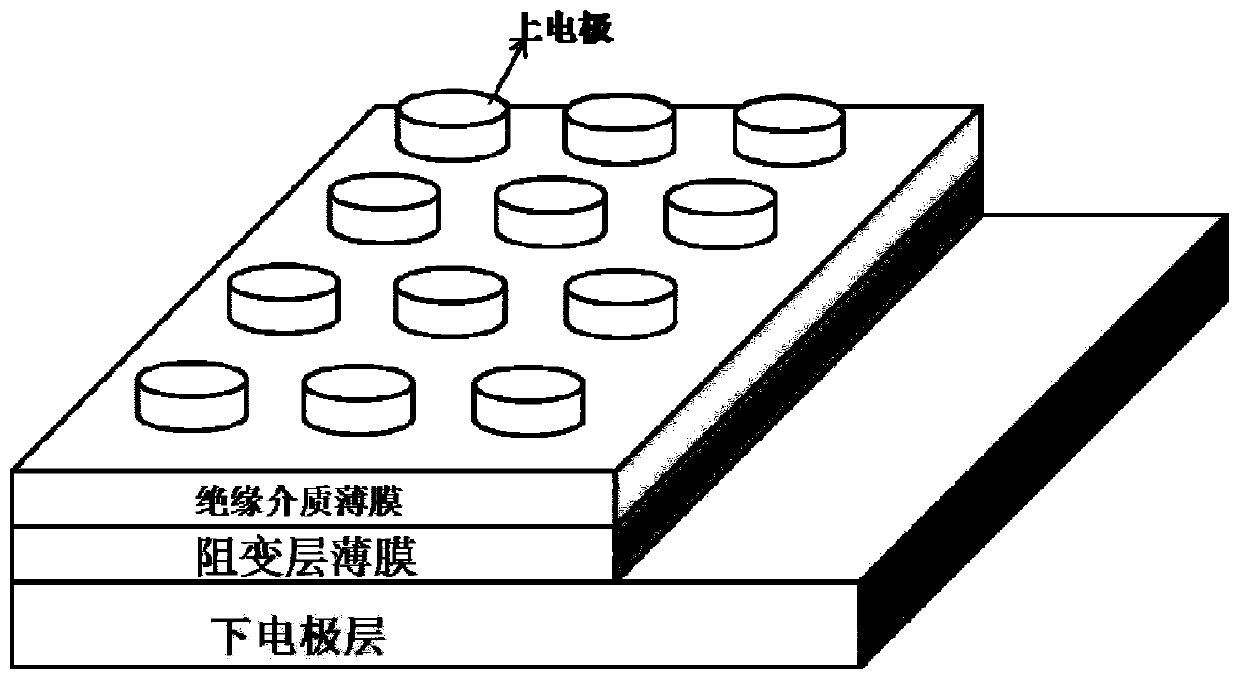

Filament mechanism-based small-area electrode resistive random access memory and preparation method thereof

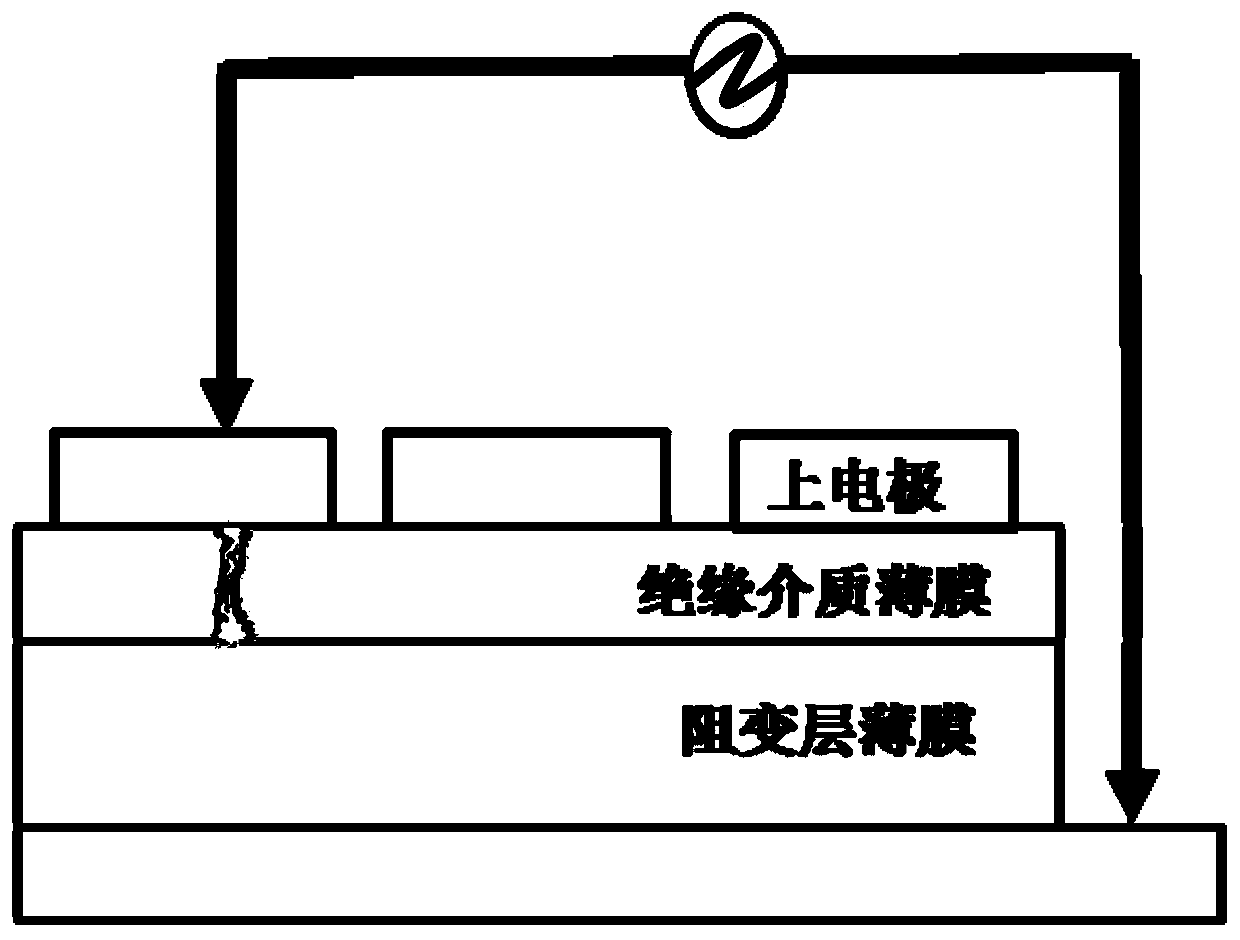

A resistive variable memory, small-area technology, applied in the direction of electrical components, etc., can solve the problems of enhancing the uncertainty of resistive variable behavior, the uncontrollable position of filament formation, and the inability to use multiple times, so as to reduce fluctuations and optimize devices , to achieve the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A copper sheet is selected as the lower electrode, and a boron nitride film is deposited on it as a resistive layer by magnetron sputtering, with a thickness of about 50nm; a plurality of aluminum metal upper electrodes with a thickness of about 150nm are deposited by using a mask plate through PVD process . The electrical characteristics are tested by a semiconductor parameter analyzer. The device is a unipolar resistive memory device that can realize unipolar operation. Its Reset voltage is concentrated around 1.3V, and the distribution range is plus or minus 0.3V, that is, Reset The voltage distribution is 1-1.6V, and the concentration is around 1.3V.

[0032] Under the same preparation process conditions, a 5nm aluminum oxide insulating layer is prepared between the upper electrode and the resistive switch layer by thermal oxidation process. The device is a unipolar resistive switch memory device, which can realize unipolar operation. Its Reset voltage is concentra...

Embodiment 2

[0034] The Pt substrate is selected as the lower electrode, and N-type TiO with a thickness of about 70 nm is grown on it by ion beam assisted reactive sputtering. 2 thin film, on TiO 2 A P-type NiO film with a thickness of about 70 nm was prepared on the film by ion beam-assisted reactive sputtering, and TiO 2 / NiO stacked structure as the resistive layer; through the ion sputtering process, through the mask plate, in the TiO 2 Au electrodes with a thickness of 30 nm were prepared on the stacked structure of NiO / NiO. The electrical characteristics are tested by a semiconductor parameter analyzer. The device is a unipolar resistive memory device that can realize unipolar operation. Its Reset voltage is concentrated around 1.5V, and the distribution range is plus or minus 0.5V, that is, Reset The voltage distribution is 1-2V, and the concentration is around 1.5V.

[0035] Under the same preparation process conditions, a BCB (benzocyclobutene) film with a thickness of 10nm wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com