Organic light emission diode device coated with capping layer and application thereof

An electroluminescent device and cover layer technology, which is applied to luminescent materials, circuits, electrical components, etc., can solve the problems of reducing the angle dependence of the device and low light extraction efficiency, and achieve the goal of improving light extraction efficiency and reducing angle dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0144] Preparation of the organic electroluminescence device of the present invention

[0145] For the material of each layer of the organic electroluminescent device of the present invention or the thickness of each layer of the organic electroluminescent device of the present invention, refer to the description provided above.

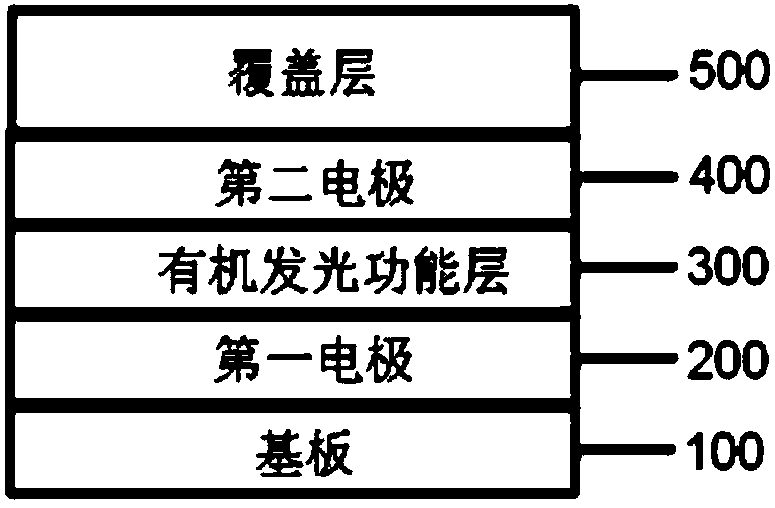

[0146] reference figure 1 The organic electroluminescence device of the present invention includes a substrate layer 100, a first electrode layer 200, an organic light-emitting function layer 300, a second electrode layer 400 and a cover layer 500.

[0147] A known method can be used to form a barrier layer (which can be composed of inorganic materials or / and organic materials to prevent foreign matter from penetrating the substrate and devices) and a wiring layer (which can include driving TFTs, capacitors, wires, and low-temperature polysilicon LTPS) on the substrate layer.

[0148] In a specific embodiment, the first electrode layer 200 may be a reflective...

Embodiment 1

[0160] An organic electroluminescence device is prepared by the following preparation steps, including:

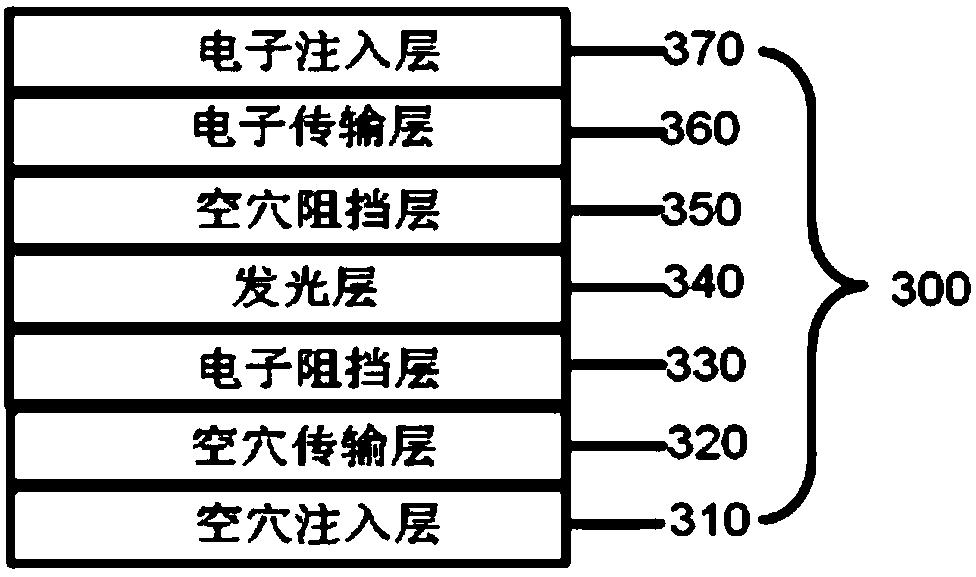

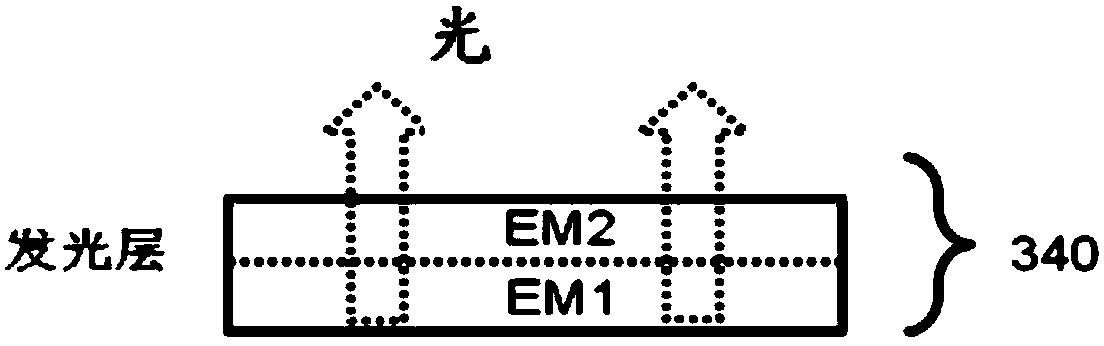

[0161] On a low-temperature polysilicon (LTPS) substrate (substrate layer 100), a 7nm ITO film (first electrode layer 200) is formed by sputtering, and etched into the required pattern, and each is ultrasonically cleaned with deionized water, acetone, and ethanol. 15 minutes, and then treated in a plasma cleaner for 2 minutes; here, the ITO electrode layer is the anode, and the hole injection layer material HAT-CN is evaporated on the ITO anode layer by vacuum evaporation method, the thickness is 10nm, this layer As the hole injection layer 310; on the hole injection layer 310, the hole transport material NPB is evaporated by vacuum evaporation method, the thickness is 110nm, this layer is the hole transport layer 320, and can also be used as a microcavity adjustment layer; On the hole transport layer 320, the electron blocking material TCTA is evaporated by a vacuum evaporat...

Embodiment 2

[0163] The preparation method is the same as device embodiment 1, but the following device structure is adopted:

[0164] ITO(7nm) / HAT-CN(10nm) / NPB(150nm) / TCTA(10nm) / CBP:Ir(PPy) 3 (90:1 0 mass ratio, 90 mass% CBP)(40nm) / / TPBI(35nm) / LiF(1nm) / Yb(1nm) / Mg:Ag(1 0:90 mass ratio, 10 mass% Mg ) (14nm) / Compound 1 of the present invention (50nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com