Process and plant for thermal treatment in a fluidized bed reactor

A fluidized bed reactor and reactor technology, applied in chemical instruments and methods, heat treatment, chemical/physical processes, etc., can solve the problems of increasing the specific energy of the calcination method, achieve the effect of reducing investment and operating costs, and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

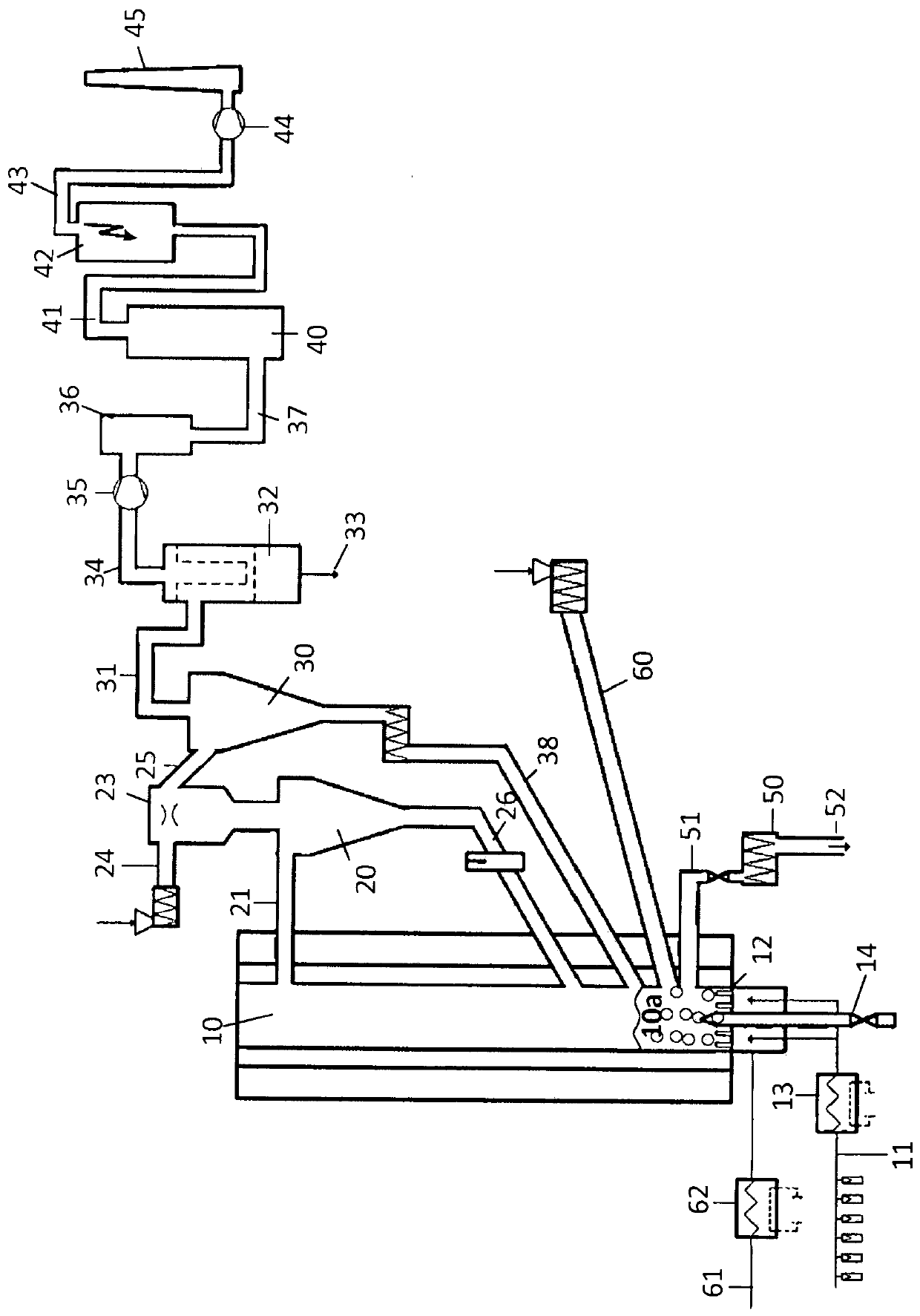

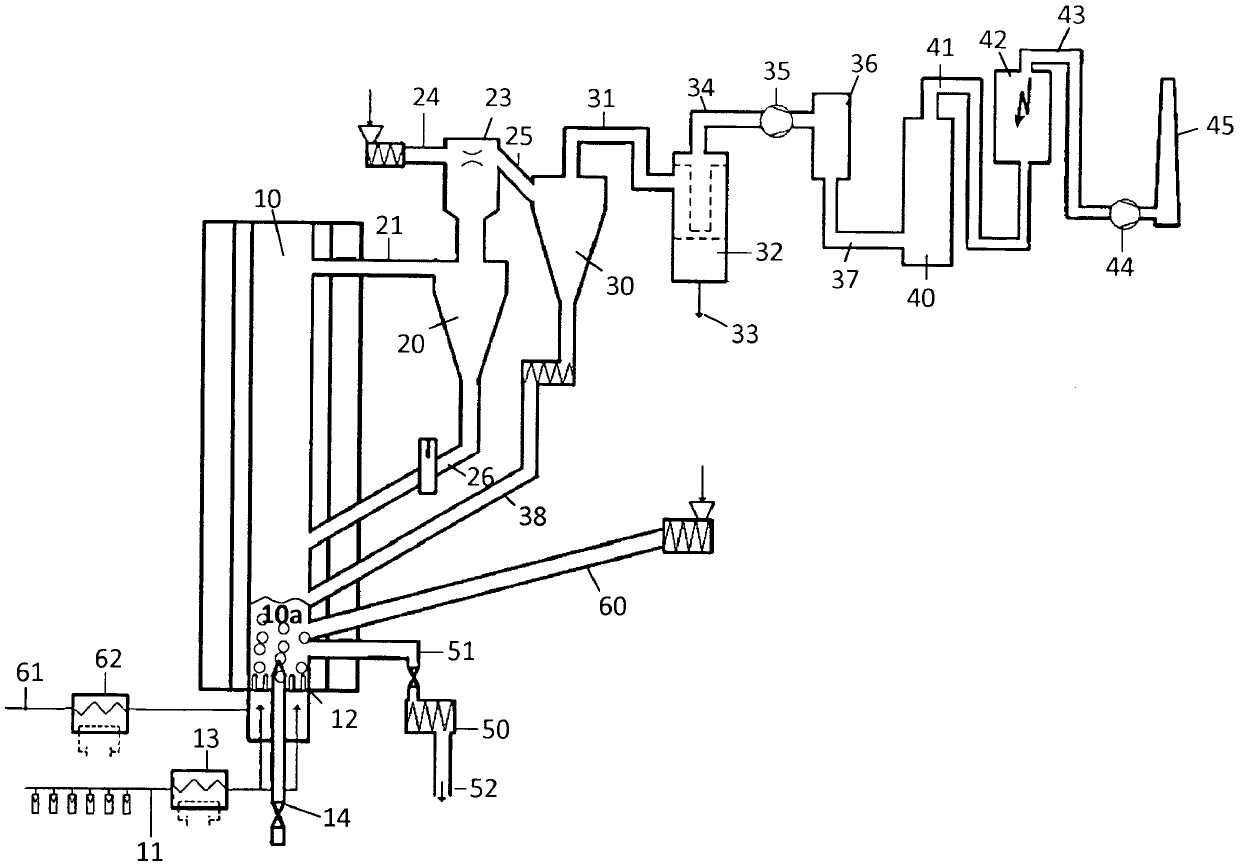

[0069] figure 1 A method of calcining minerals using biogas as fuel and a novel injection system is shown. Gas with the desired composition enters nozzle grate 12 via conduit 11 and fluidizes the material in reactor 10 . Before entering the nozzle grate 12, the air may be heated to the required temperature by an electric preheating system 13. Temperatures were measured at various locations and the data recorded.

[0070] Biogas is injected into the reactor 10 as fuel via the lance 13 . The fuel is combusted in the reactor to thermally treat the solid particles in the fluidized bed 10 .

[0071] The solids entrained by the reactor flue gas in the gas-solid mixture are recycled to the fluidized bed 10a through the conduit 31 and the cyclone separator 20 . The separated solids fraction comprising at least 60% by weight of the solids contained in the discharged gas-solid mixture is recycled to the reactor 10 via conduit 26 . The dust laden gas leaving the cyclone 20 flows via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com