High-strength aluminum/magnesium dissimilar alloy connector containing intermediate layer, and preparation method thereof

An intermediate layer, high-strength technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as the decline in mechanical properties of joints, achieve the effects of improving organizational structure, improving mechanical properties, and reducing welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a high-strength aluminum / magnesium dissimilar alloy joint containing an intermediate layer in the present invention comprises the following steps:

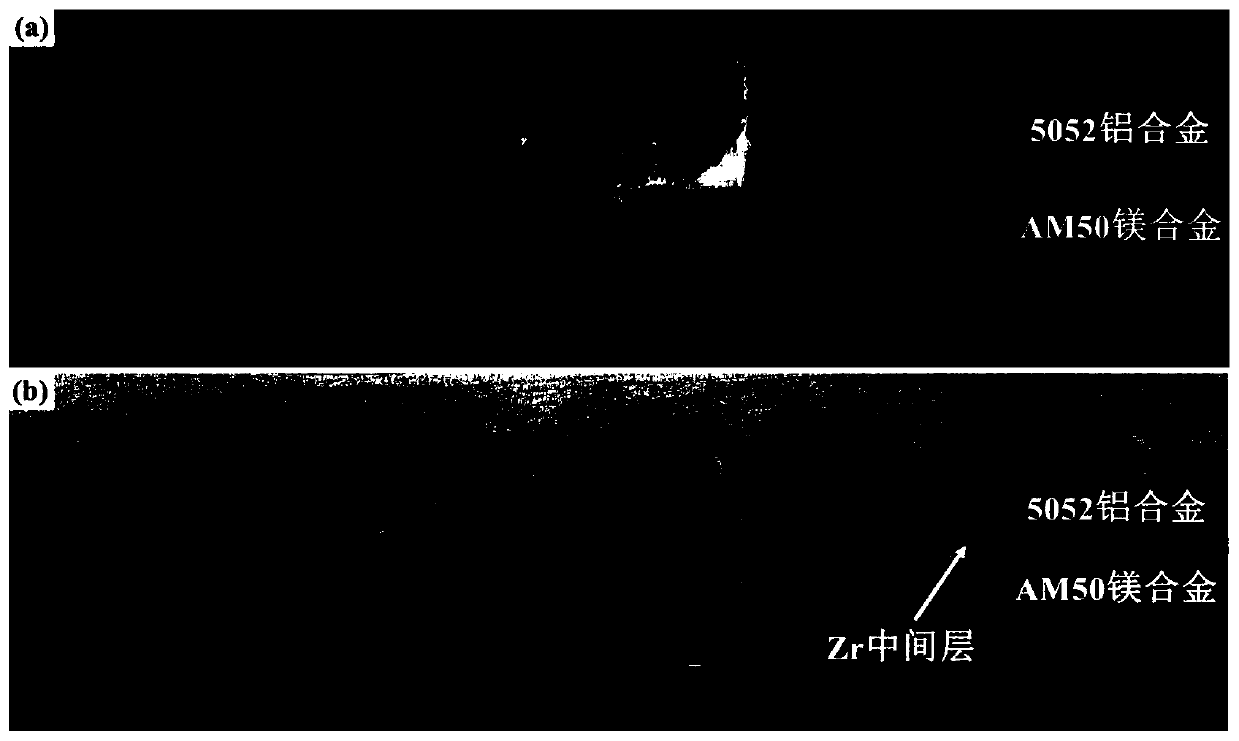

[0028] The first step: Pretreatment before welding

[0029] Pre-treat the surface of the aluminum alloy sheet and magnesium alloy sheet to be welded, and polish it on 500#, 1000#, 1500#, 2000# and 2500# water sandpaper in turn, and then ultrasonically clean it in acetone and alcohol for 10-20 minutes, and cool air Blow dry; overlap the plates to be welded, from bottom to top are magnesium alloy, Zr foil and aluminum alloy, the size of aluminum alloy plate and magnesium alloy plate is 300mm×150mm×3mm, and the width of the overlapping area is 50-75mm , preferably 55-70 mm, the thickness of the Zr foil is 0.05-0.25 mm, preferably 0.10-0.20 mm, the length and width of the Zr foil are consistent with the size of the overlapping area, and then the welding material after the overlapping is fixed.

[0030] S...

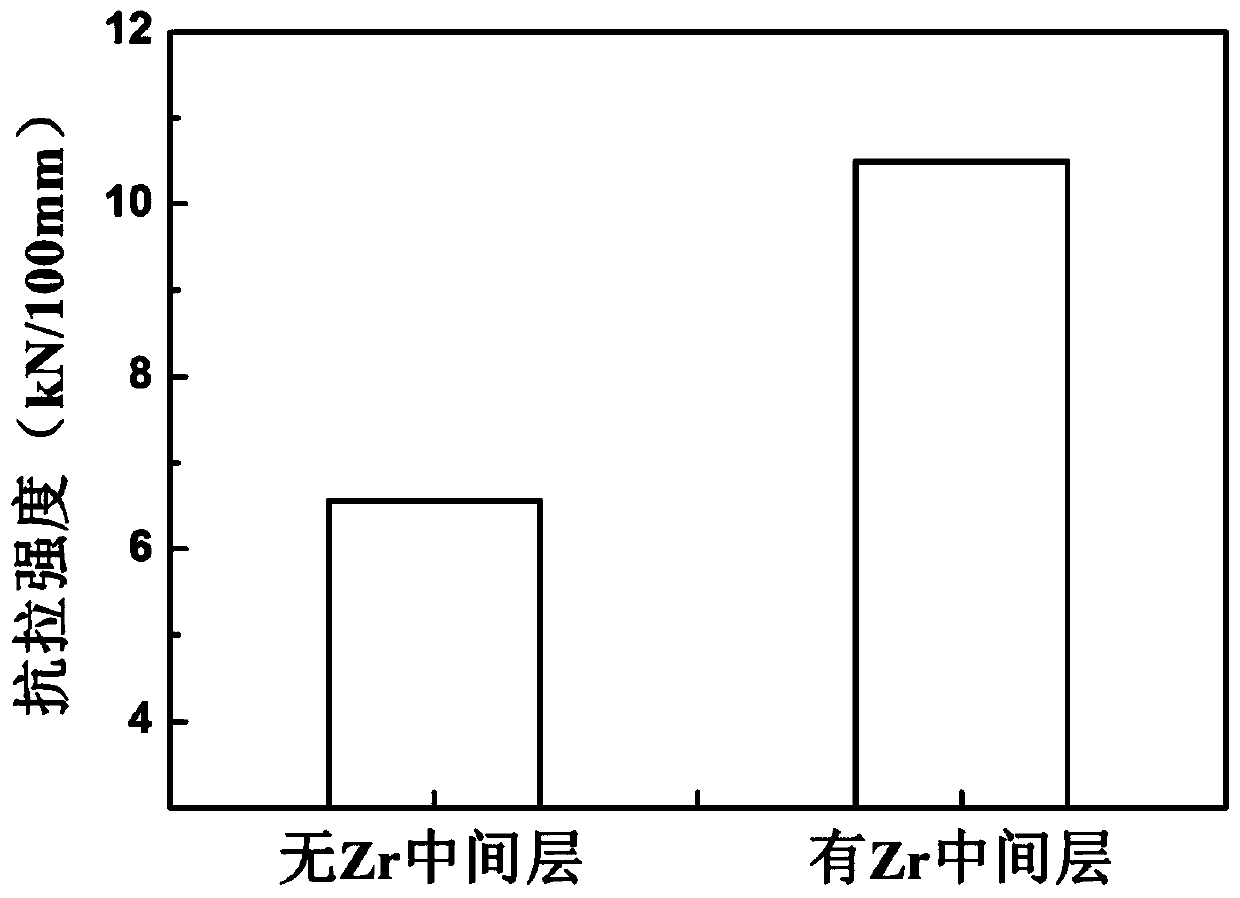

Embodiment 1

[0036] The first step: Pretreatment before welding

[0037] Pre-treat the surface of the 5052 aluminum alloy plate and AM50 magnesium alloy plate to be welded, and polish it on 500#, 1000#, 1500#, 2000# and 2500# water sandpaper in turn, and then ultrasonically clean it in acetone and alcohol for 15 minutes, and cool air Blow dry; Lap the plates to be welded, from bottom to top, they are magnesium alloy, Zr foil and aluminum alloy. The thickness of the foil is 0.10mm, the length and width of the Zr foil are consistent with the size of the overlapping area, and then the welding consumables after the overlapping are fixed.

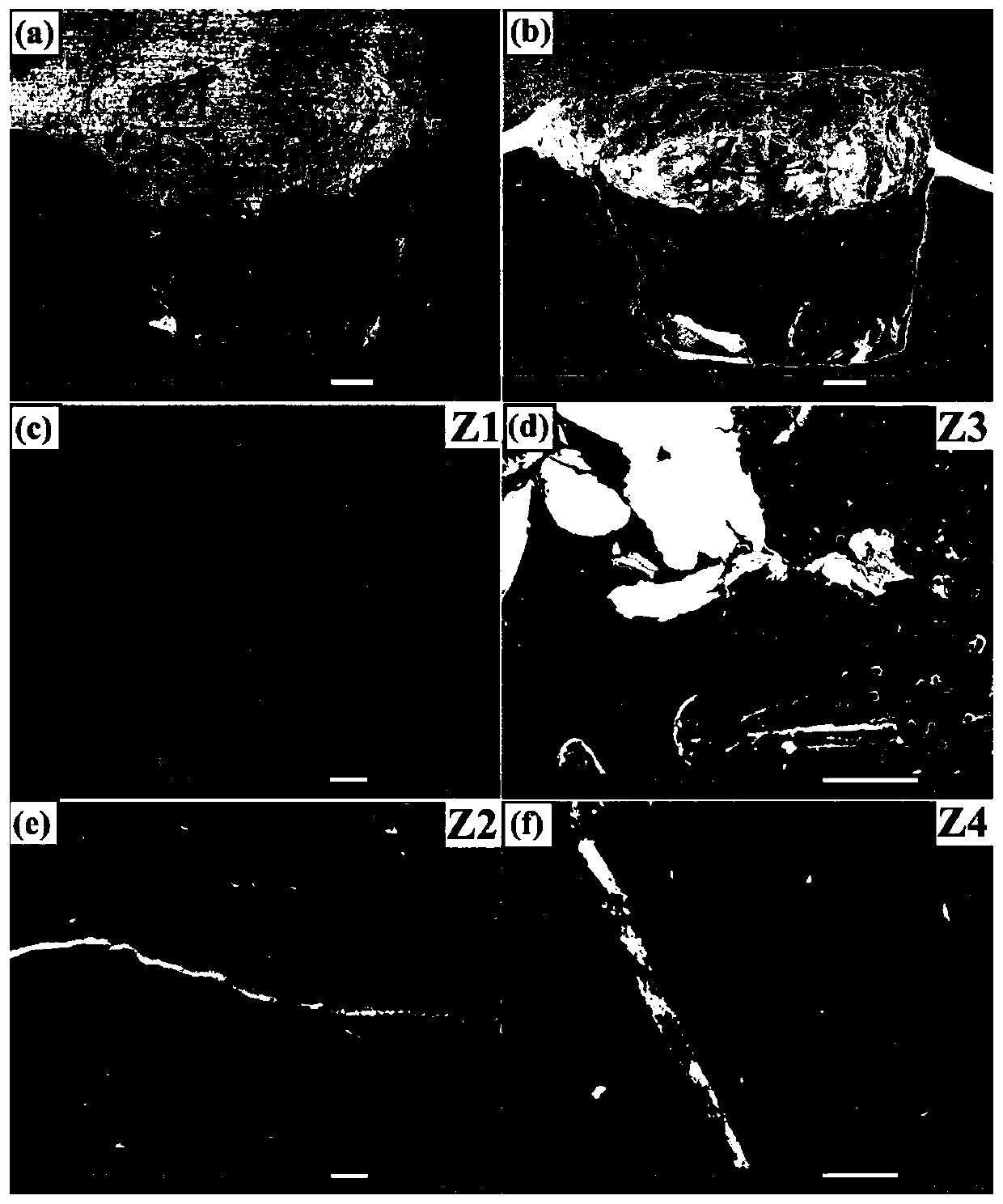

[0038] Step Two: Friction Stir Welding

[0039] Fix the welding consumables after the first step of overlapping on the welding workbench. During the welding process, immerse the welding consumables in a water cooling device to cool down. The temperature of the cooling water is 15°C; then use a small gantry friction stir welding machine for welding. Carry o...

Embodiment 2

[0052] The first step: Pretreatment before welding

[0053] The surface of the 5086 aluminum alloy sheet and the AZ31 magnesium alloy sheet to be welded are pretreated, polished on 500#, 1000#, 1500#, 2000# and 2500# water sandpaper in turn, and then ultrasonically cleaned in acetone and alcohol for 15 minutes, cold air Blow dry; Lap the plates to be welded, from bottom to top, they are magnesium alloy, Zr foil and aluminum alloy. The thickness of the foil is 0.15mm, the length and width of the Zr foil are consistent with the size of the overlapping area, and then the welding consumables after the overlapping are fixed.

[0054] Step Two: Friction Stir Welding

[0055] Fix the welding consumables after the first step of overlapping on the welding workbench. During the welding process, immerse the welding consumables in a water cooling device to cool down. The temperature of the cooling water is 20°C; then use a small gantry friction stir welding machine for welding. Carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com