Method for forming reactor internal integral compression structure

A compact structure and integral technology, applied in the direction of additive processing, etc., can solve the problems of complex welding process, large welding deformation, large processing deformation, etc., to improve the forming quality, shorten the manufacturing cycle, and have no difference in material properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

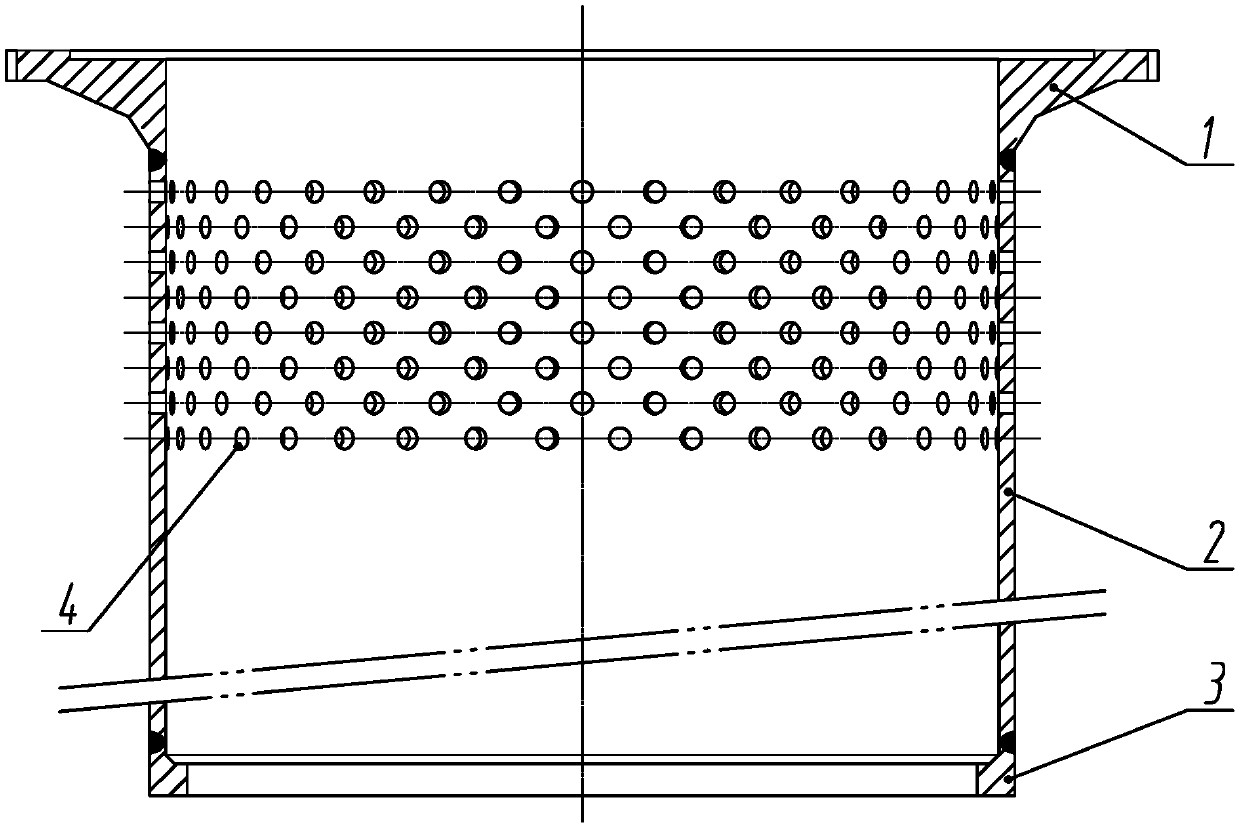

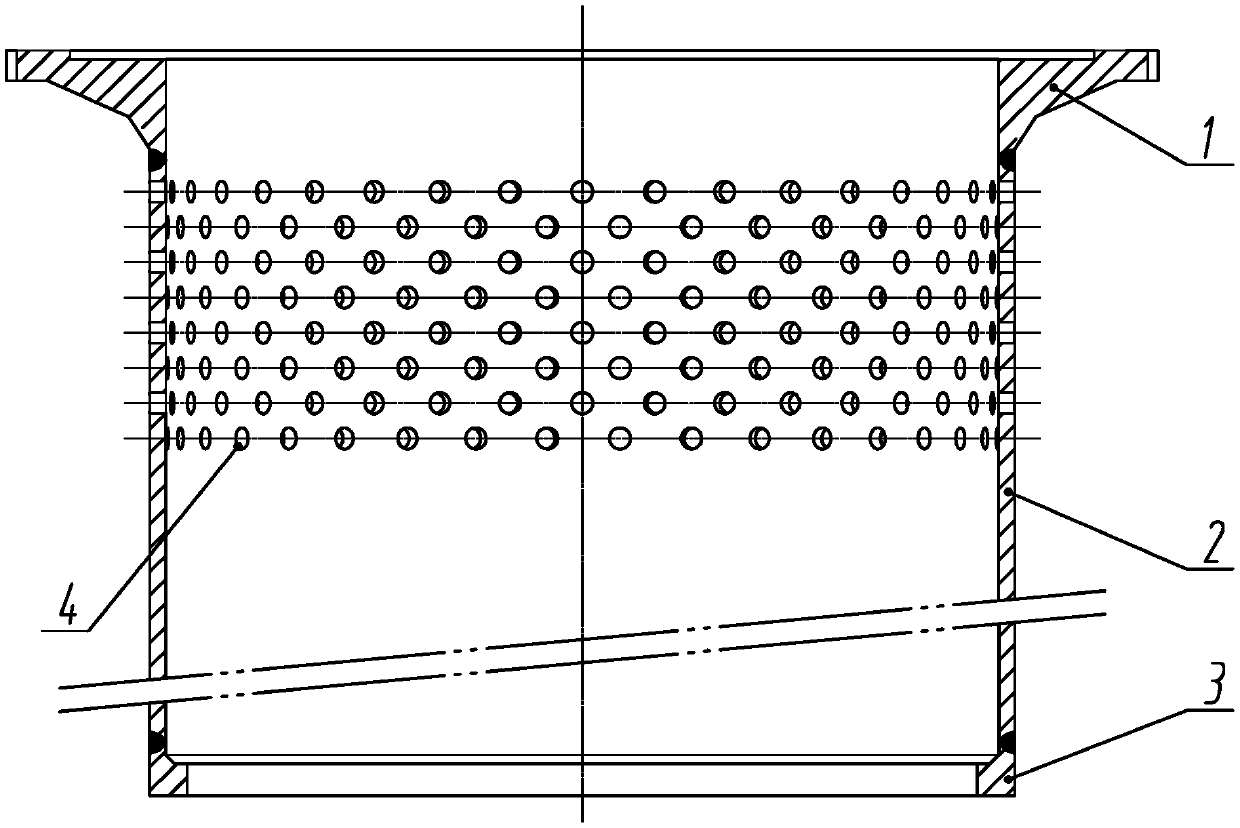

[0076] In the compression structure design of the existing reactor internals, based on the assembly and welding process of each component, the compression structure is divided into an upper support flange (1), a skirt tube (2) and a lower support plate (3), such as attached figure 1 . The skirt (2) is rolled into a cylindrical structure by sheet metal, and is formed by full penetration welding along the axial direction of the cylindrical structure, and then the upper support flange (1), skirt (2) and lower support plate (3) are assembled Afterwards, circumferential full-penetration welding is carried out, and then multi-layer radially uniformly distributed flow-through holes (4) are processed to manufacture a complete compacting structure.

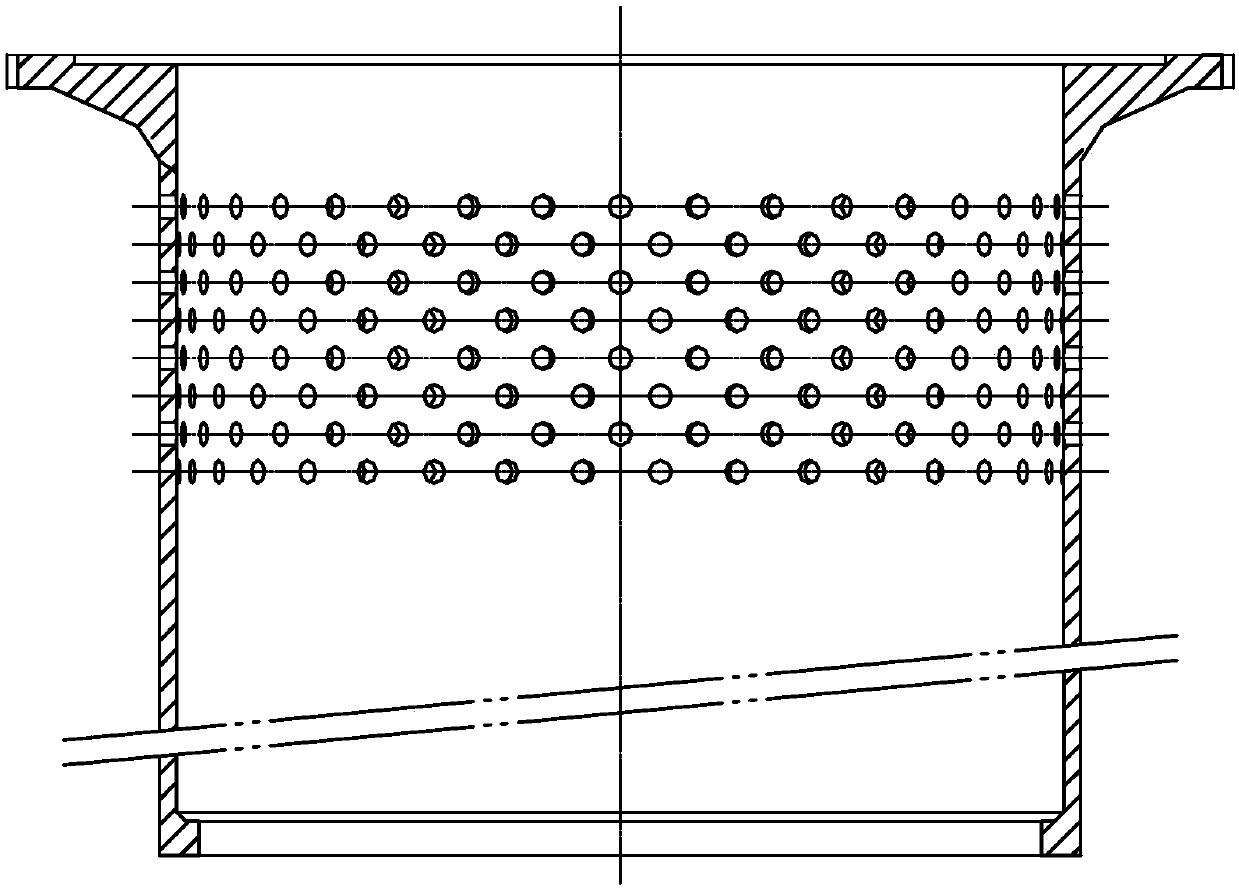

[0077] The present invention is based on the electro-fusion additive manufacturing technology, and designs the compression structure as an integral structure, that is, cancels the connection welds between the structures and the special re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com