Preparation method of hexagonal prism zinc oxide

A technology of zinc oxide and prisms, which is applied in the technical field of asymmetric growth of zinc oxide crystals and in the field of zinc oxide synthesis of controllable crystal planes, can solve problems such as difficult ratio regulation, achieve smooth surface, and realize controllable synthesis technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing asymmetrically grown zinc oxide crystals. The specific process includes the following steps: 1) preparing a certain volume fraction of ethylene glycol mixed solution, adding zinc acetate and urotropine in sequence after ultrasonic dispersion, and ultrasonically dissolving ; 2) Put the above mixed solution in an oven to react at high temperature for a period of time, wash and filter with ethanol, and dry; 3) Finally, calcinate the obtained powder at high temperature.

[0023] In order to obtain hexagonal zinc oxide with different surface morphology, the volume fraction and concentration of the mixed solution were adjusted, and the reaction temperature and time were adjusted at the same time. The experimental results were compared to obtain the zinc oxide crystal plane under different parameters.

Embodiment 1

[0025] 1) Preparation of mixed solution

[0026] Accurately weigh 16ml of ethylene glycol and 24ml of deionized water, and after ultrasonic mixing, add 5.268 g of zinc acetate and 3.364 g of urotropine in sequence, and ultrasonically dissolve.

[0027] 2) Hydrothermal reaction

[0028] The above mixed solution was transferred to a 100ml hydrothermal kettle, then placed in an oven at 95°C for 24 hours, and then taken out after natural cooling.

[0029] 3) high temperature calcination

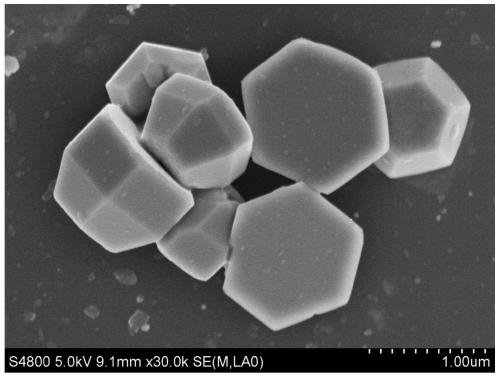

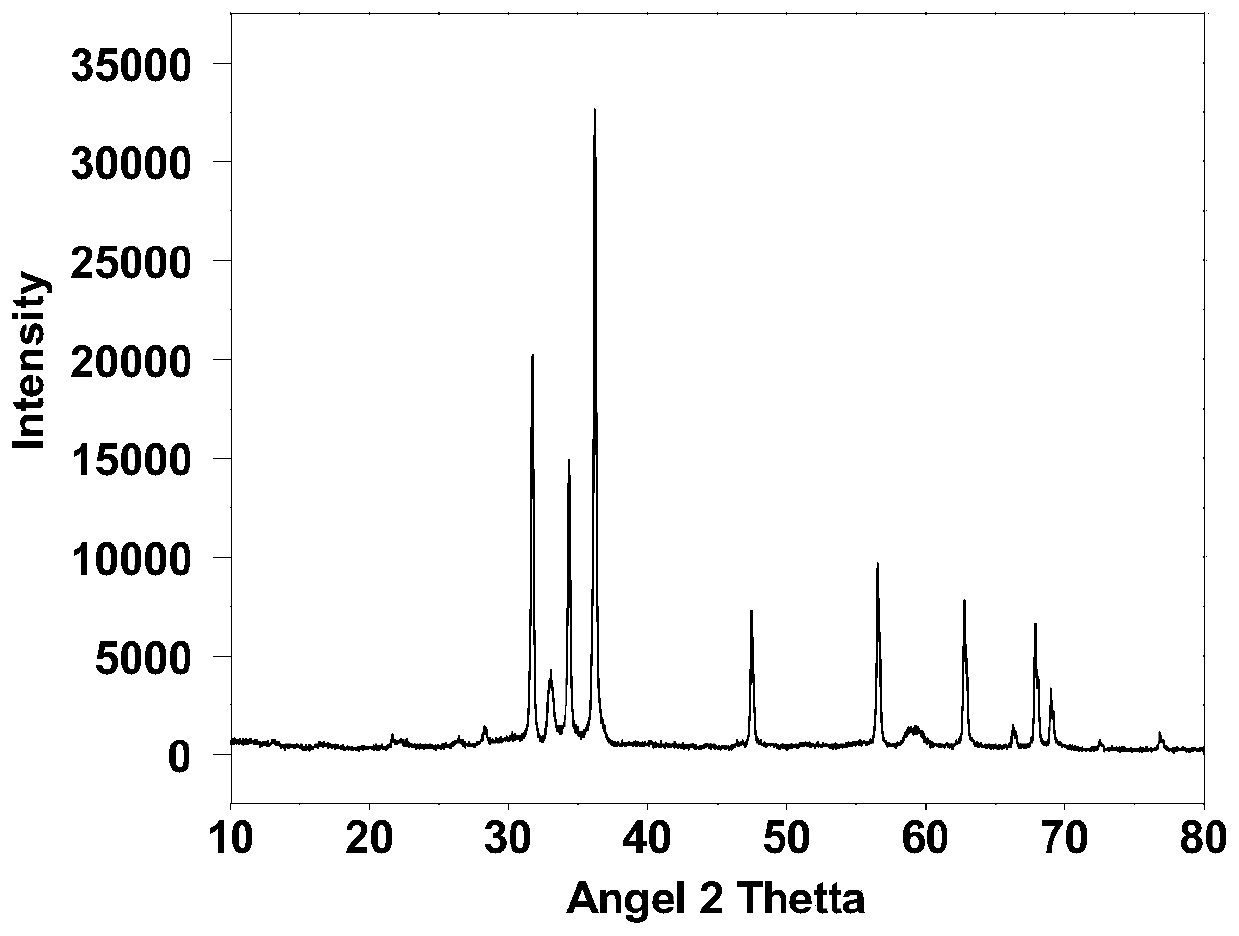

[0030] The above product was washed and filtered three times with ethanol, then dried at 80° C., and finally, the obtained powder was calcined in a muffle furnace at 300° C. for 2 h. The SEM picture of the resulting product is as figure 1 As shown, the XRD pattern is as figure 2 shown.

[0031] Observed figure 1 It can be obtained that the product zinc oxide is in the shape of a hexagonal prism, the upper and lower bottom surfaces are of different sizes, and the sides are not simple symmet...

Embodiment 2

[0033] 1) Preparation of mixed solution

[0034] Accurately weigh 24ml of ethylene glycol and 24ml of deionized water, add 5.268g of zinc acetate and 3.364g of urotropine in sequence after ultrasonic mixing, and ultrasonically dissolve.

[0035] 2) Hydrothermal reaction

[0036] The above mixed solution was transferred to a 100ml hydrothermal kettle, then placed in an oven at 95°C for 24 hours, and then taken out after natural cooling.

[0037] 3) high temperature calcination

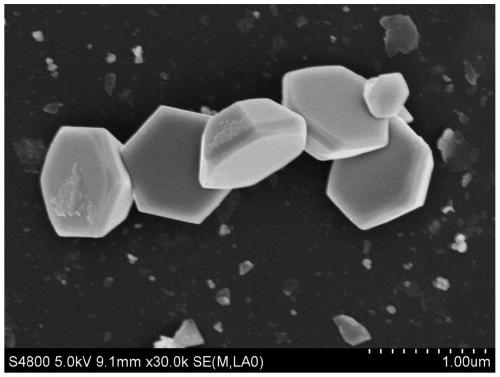

[0038] The above product was washed and filtered three times with ethanol, then dried at 80° C., and finally, the obtained powder was calcined in a muffle furnace at 300° C. for 2 hours. The SEM picture of the resulting product is as image 3 As shown, the XRD pattern is as Figure 4 shown.

[0039] Observed image 3 It can be obtained that the product zinc oxide is still in the form of a hexagonal prism, and the ratio of the upper and lower bottom surfaces is obviously smaller than that of Case 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com