Preparation method of solvent-free polyurethane adhesive

A polyurethane adhesive, solvent-free technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as long open time, adhesive penetration, inability to achieve large-scale industrial production, and achieve good mechanical properties. The effect of strength, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of solvent-free polyurethane adhesive comprises the steps:

[0031] Step 1, the preparation of polyurethane emulsion:

[0032] In a three-neck flask equipped with a thermometer and a stirring rod, first put the self-made polyester diol in N2 Under protection, dehydrate under vacuum at 115°C for 100min, then cool to 70°C, adjust the rotating speed to 200r / min, slowly add isophorone diisocyanate and dibutyltin dilaurate (catalyst, the dosage is 0.01% of the mass of the reactant), and React at 90°C for 2.5h, use the di-n-butylamine method to measure the mass fraction of -NCO groups, when it reaches the theoretical value (9.59%-9.69%), cool to 78°C, add metered dimethylolbutyric acid and Dibutyltin dilaurate (the amount used is 0.01% of the mass of the reactant), adjust the rotating speed to 250r / min, and react at 80°C for 2.5h; then use the di-n-butylamine method to measure the mass fraction of the -NCO group, when it reaches the theoretical value A...

Embodiment 1

[0050] The preparation method of solvent-free polyurethane adhesive comprises the steps:

[0051] Step 1, the preparation of polyurethane emulsion:

[0052] In a three-neck flask equipped with a thermometer and a stirring rod, first put the self-made polyester diol in N 2 Under protection, dehydrate under vacuum at 115°C for 100min, then cool to 70°C, adjust the rotating speed to 200r / min, slowly add isophorone diisocyanate and dibutyltin dilaurate (catalyst, the dosage is 0.01% of the mass of the reactant), and React at 90°C for 2.5h, use the di-n-butylamine method to measure the mass fraction of -NCO groups, when it reaches the theoretical value (9.59%-9.69%), cool to 78°C, add metered dimethylolbutyric acid and Dibutyltin dilaurate (the amount used is 0.01% of the mass of the reactant), adjust the rotating speed to 250r / min, and react at 80°C for 2.5h; then use the di-n-butylamine method to measure the mass fraction of the -NCO group, when it reaches the theoretical value ...

Embodiment 2

[0063] The preparation method of solvent-free polyurethane adhesive comprises the steps:

[0064] Step 1, the preparation of polyurethane emulsion:

[0065] In a three-neck flask equipped with a thermometer and a stirring rod, first put the self-made polyester diol in N 2 Under protection, dehydrate under vacuum at 115°C for 100min, then cool to 70°C, adjust the rotating speed to 200r / min, slowly add isophorone diisocyanate and dibutyltin dilaurate (catalyst, the dosage is 0.01% of the mass of the reactant), and React at 90°C for 2.5h, use the di-n-butylamine method to measure the mass fraction of -NCO groups, when it reaches the theoretical value (9.59%-9.69%), cool to 78°C, add metered dimethylolbutyric acid and Dibutyltin dilaurate (the amount used is 0.01% of the mass of the reactant), adjust the rotating speed to 250r / min, and react at 80°C for 2.5h; then use the di-n-butylamine method to measure the mass fraction of the -NCO group, when it reaches the theoretical value ...

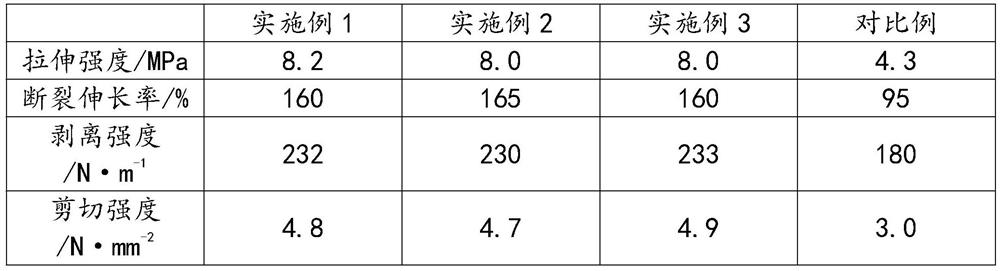

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com