Flower fruit fragrance type cigarette paper and preparation method thereof

A flower and fruit aroma, cigarette paper technology, applied in the directions of tobacco, papermaking, wrapping paper, etc., can solve the problems of raising the production and preparation cost of cigarette paper, poor smoking taste of cigarettes, poor aroma stability, etc. Low rate, reduce the cost of flavoring, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

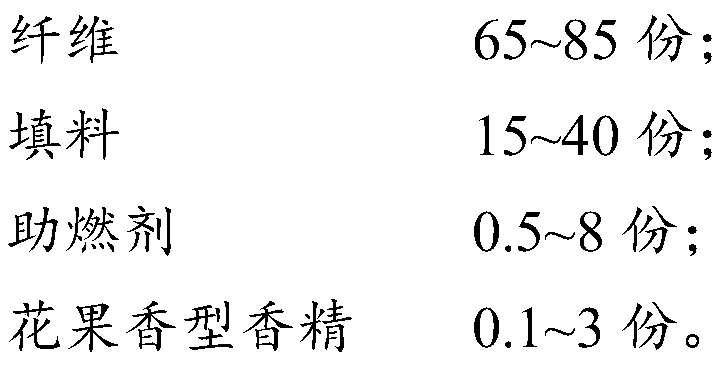

[0037] The present invention also provides a preparation method for the above-mentioned fruity-flowery cigarette paper, comprising the following steps:

[0038] (1) After mixing the fibers with water, disintegrating and beating are performed successively to obtain fiber slurry;

[0039](2) papermaking after mixing the fiber slurry and the filler to obtain the mixed slurry;

[0040] (3) performing shaping, dehydration, embossing and first drying on the mixed slurry in sequence to obtain the first dry paper web;

[0041] (4) Surface sizing and second drying are performed sequentially on the first dried paper web to obtain flowery and fruity flavored cigarette paper.

[0042] In the invention, the fibers are mixed with water and then crushed and beaten in sequence to obtain the fiber slurry. In the present invention, the mass concentration of fibers in the mixture of fibers and water is preferably 2-5%. The present invention has no special requirement on the mixing method of f...

Embodiment 1

[0063] Take 800kg wood pulp fiber, add 23m 3 water, beating to a degree of beating after disintegration is 83 °, adding 350kg calcium carbonate (particle diameter is 20 μm) in the slurry, mixing and papermaking to obtain a mixed slurry.

[0064] The mixed slurry is sequentially subjected to shaping, dehydration, embossing and first drying to obtain a first dry paper web; wherein the starting temperature of the first drying is 65°C, and the end temperature is 105°C, and the obtained first dry paper web is The humidity is 8%.

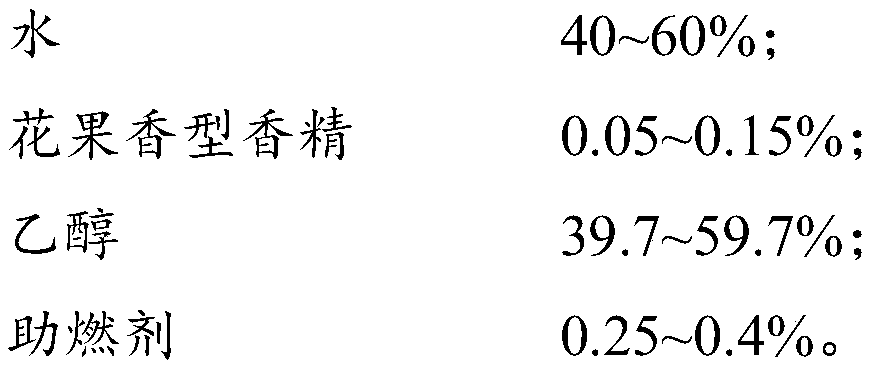

[0065] Add 1.25kg sweet orange essential oil and 1.25kg tangerine peel essential oil into 400kg of ethanol (95% volume concentration) according to floral and fruit essential oils, and stir at a constant speed for 30 minutes to obtain a floral and fruity aroma solvent. In the state of constant stirring, 400kg of water is added to the floral and fruity fragrance solvent at a constant speed, and a mixed solution in which water accounts for 50% of the volume...

Embodiment 2

[0079]Get 650kg wood pulp fiber and 150kg hemp pulp fiber to mix, add 23m 3 Water, after disintegrating, circulate beating until the degree of beating is 83 °, add 450kg talcum powder (particle diameter is 2 μm), mix, and obtain mixed slurry after papermaking.

[0080] The mixed slurry was sequentially subjected to forming, dehydration, embossing and first drying to obtain the first dry paper web; wherein the starting temperature of the first drying was 60°C, the ending temperature was 100°C, and the time was 12s; the obtained first drying A dry web has a moisture content of 8%.

[0081] Add 3kg of vanilla essential oil into 350kg of ethanol (95% volume concentration) according to the flower and fruit essential oil, and stir at a constant speed for 60 minutes to obtain the flower and fruit fragrance type solvent. In the state of uniform stirring, 450kg of water was added to the floral and fruity fragrance solvent at a constant speed, and configured into a mixed solution in wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| beating degree | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com