Aerogel composite glass and manufacturing method thereof

A technology for combining glass and a manufacturing method, which is applied in the fields of visual, thermal insulation, lighting, heat insulation and sound insulation materials, can solve the problems of easy damage, difficult market promotion, difficult aerogel preparation, etc., so as to improve thermal performance and reduce The effect of secondary radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The airgel composite glass was prepared by the following steps:

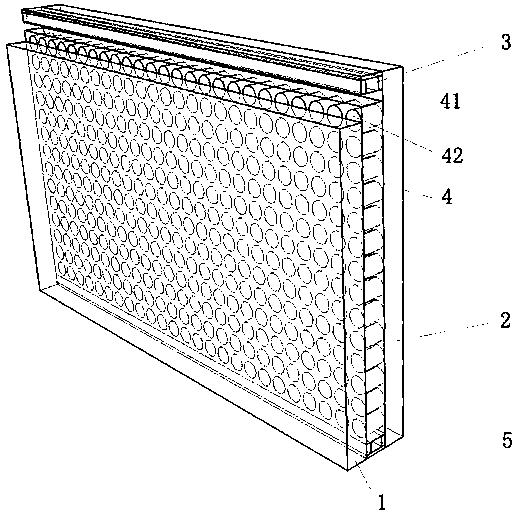

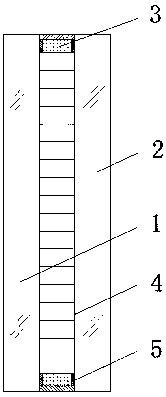

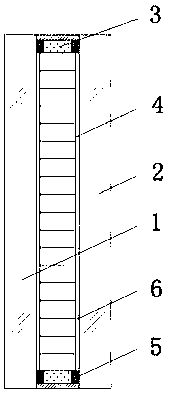

[0082] (1) Arrange several airgels 42 vertically between two pieces of float glass (1, 2), wherein the airgels 42 are cylindrical in shape, with a pore diameter of 10 mm, a height of 9 mm, and a wall thickness of 0.1 mm, use butyl sealant 5 and bridge-breaking aluminum spacer frame 3 to bond around two pieces of float glass (1, 2), reserve at least one injection port, and then inject molten polycarbonate through the injection port cooling and forming in the gap between the airgel 42 to obtain a composite honeycomb core 4 placed between two pieces of float glass (1, 2);

[0083] (2) Use a spacer to seal the injection molding port, and then use silicone sealant 5 to seal the U-shaped gap formed between the bridge-breaking aluminum spacer frame 3 and the two pieces of float glass (1, 2).

[0084] The airgel composite glass obtained through the above steps has a heat transfer coefficient of 1.24W / m 2 K, the...

Embodiment 2

[0086] (1) Arrange several aerogels 42 vertically between two pieces of float glass (1, 2), wherein the shape of the aerogels 42 is a regular hexagonal prism, the aperture is 20mm, the height is 12mm, and the thickness of the hole wall is 0.5mm, use butyl sealant 5 and bridge-breaking aluminum spacer frame 3 to bond around two pieces of float glass (1, 2), reserve at least one injection port, and then inject molten polypropylene through the injection port cooling and forming in the gap between the airgel 42 to obtain a composite honeycomb core 4 placed between two pieces of float glass (1, 2);

[0087] (2) Use a spacer to seal the injection molding port, and then use silicone sealant 5 to seal the U-shaped gap formed between the bridge-breaking aluminum spacer frame 3 and the two pieces of float glass (1, 2).

[0088] The airgel composite glass obtained through the above steps has a heat transfer coefficient of 0.98W / m 2 K, the visible light transmittance is 70%, and the sola...

Embodiment 3

[0090] (1) Arrange several aerogels 42 vertically between two transparent polycarbonate plates (1, 2), wherein the shape of the aerogels 42 is a square prism with a pore diameter of 80 mm and a height of 40 mm. The thickness is 1mm, using epoxy resin sealant 5 and fiber-reinforced plastic spacer frame 3 to bond around two transparent polycarbonate plates (1, 2), reserve at least one injection port, and then pour the molten poly Methyl acrylate is injected into the gap between the airgel 42 through the injection port, cooled and molded to obtain a composite honeycomb core 4 placed between two transparent polycarbonate plates (1, 2);

[0091] (2) Use a spacer to seal the injection port, and then use silicone sealant 5 to seal the U-shaped gap formed between the fiber-reinforced plastic spacer frame 3 and the two transparent polycarbonate plates (1, 2) .

[0092] The airgel composite glass obtained through the above steps has a heat transfer coefficient of 0.31W / m 2 K, the visi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com