Method and device of measuring pellet shape and profile parameters based on bilateral misalignment differential confocal and interference

A differential confocal and parameter measurement technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of non-uniform value benchmarks, inability to fully reveal the phenomenon and laws of target shot structure changes, and target shot damage, etc. Achieve the effect of improving fixed focus sensitivity and signal-to-noise ratio, improving anti-environmental interference capability, and eliminating common mode noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

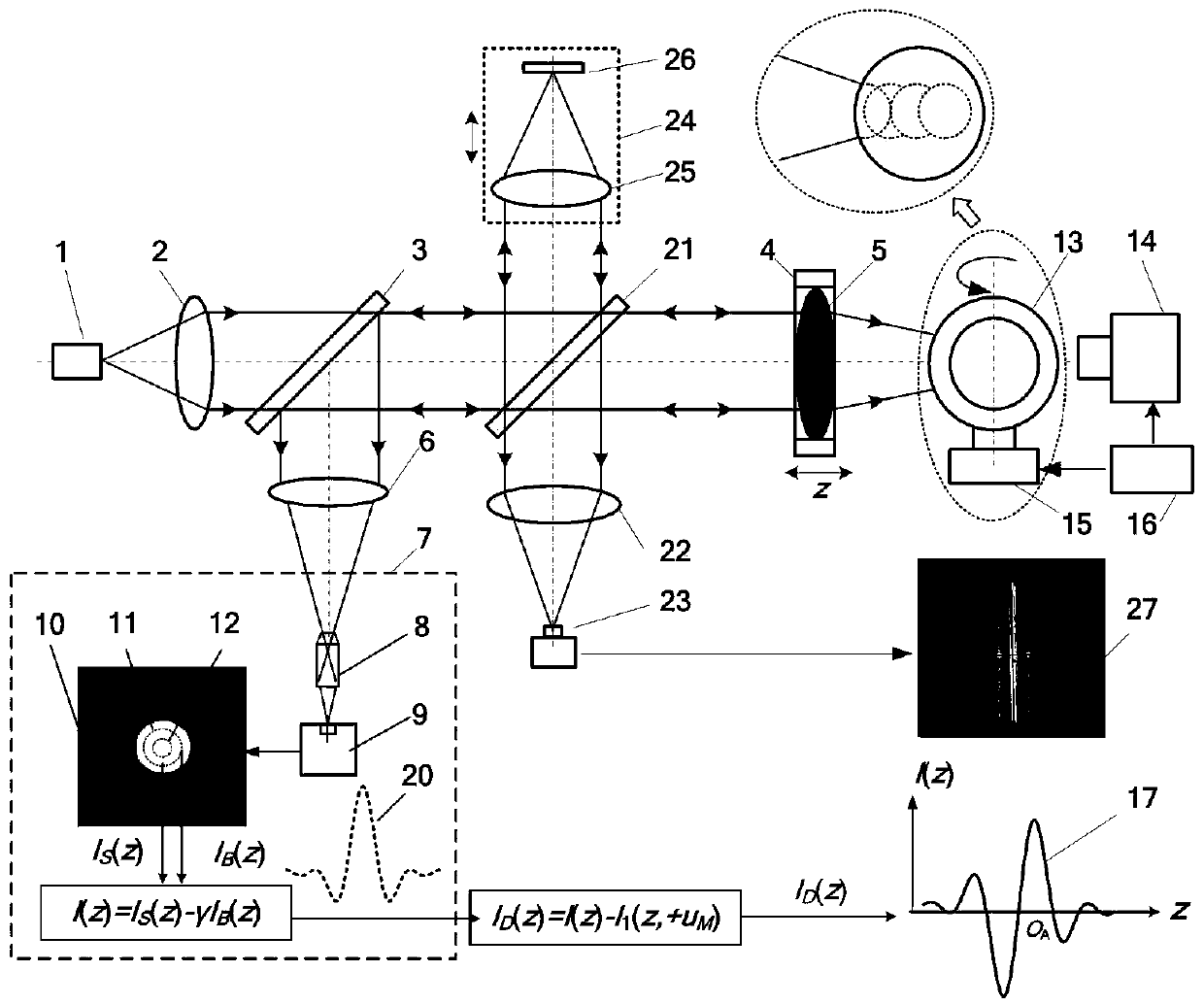

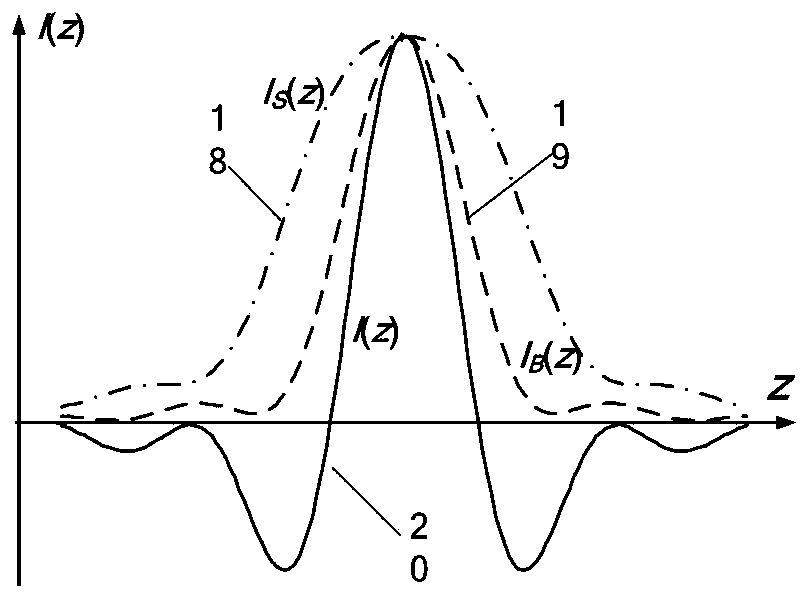

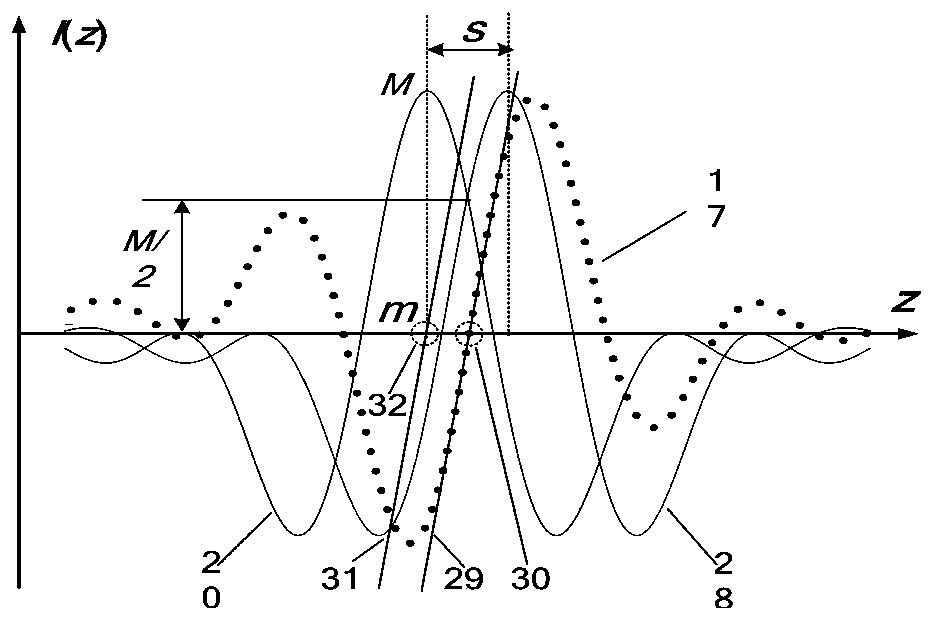

[0055] like figure 1 As shown, the light source system 1 uses a point light source, and the divergent light beam emitted by the point light source is collimated into a parallel light beam by the collimator lens 2. The illuminating light beam, the transmitted illuminating light beam is converged to one point by the measuring objective lens 5 to illuminate the fusion target pill 13 and be reflected. The reflected beam carrying the information of the fusion target pellet 13 passes through the measuring objective lens 5 to form a measuring beam, which is divided into a transmitted measuring beam and a reflected measuring beam by the second beam splitter 21, and the reflected measuring beam is reflected by the first beam splitting mirror 3 and then converged The mirror 6 enters the transverse subtraction confocal detection system 7; the reflected illumination beam enters the interference arm 24 and is reflected and then transmitted by the second beam splitter 21 to form a common pa...

Embodiment 2

[0078] like Figure 5 As shown, the light source system 1 is composed of a laser 18 , a light source converging mirror 19 located in the emitting direction of the laser 18 , and a light source pinhole 20 located at the focal point of the light source converging mirror 19 .

[0079] The measurement process is the same as in Example 1.

Embodiment 3

[0081] like Image 6 As shown, in the comprehensive measurement device for the shape and profile parameters of the laser confocal interference nuclear fusion target pellet, the light source system 1 consists of a laser 18, a light source converging mirror 19 located in the laser 18 exit direction, and a light source pinhole 20 located at the focus position of the light source converging mirror 19 composition. Place the collimator lens 2, the first beam splitter 3 in sequence along the light source exit direction, the second beam splitter 21, the objective lens drive system 4, and the measuring objective lens 5 placed in sequence along the transmission direction of the first beam splitter 3, along the second beam splitter 21 Place the interference arm 24 made up of the interference converging mirror 25 and the reflector 26 positioned at the focal plane of the interference converging mirror 25 in the reflection direction, place the converging mirror 6 and the lateral subtraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com