Automatic LED (Light-Emitting Diode) feature parameter collecting system

A technology of automatic collection of characteristic parameters, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as long aging test process, and achieve the effect of accurate and continuous testing, high reliability and high precision of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

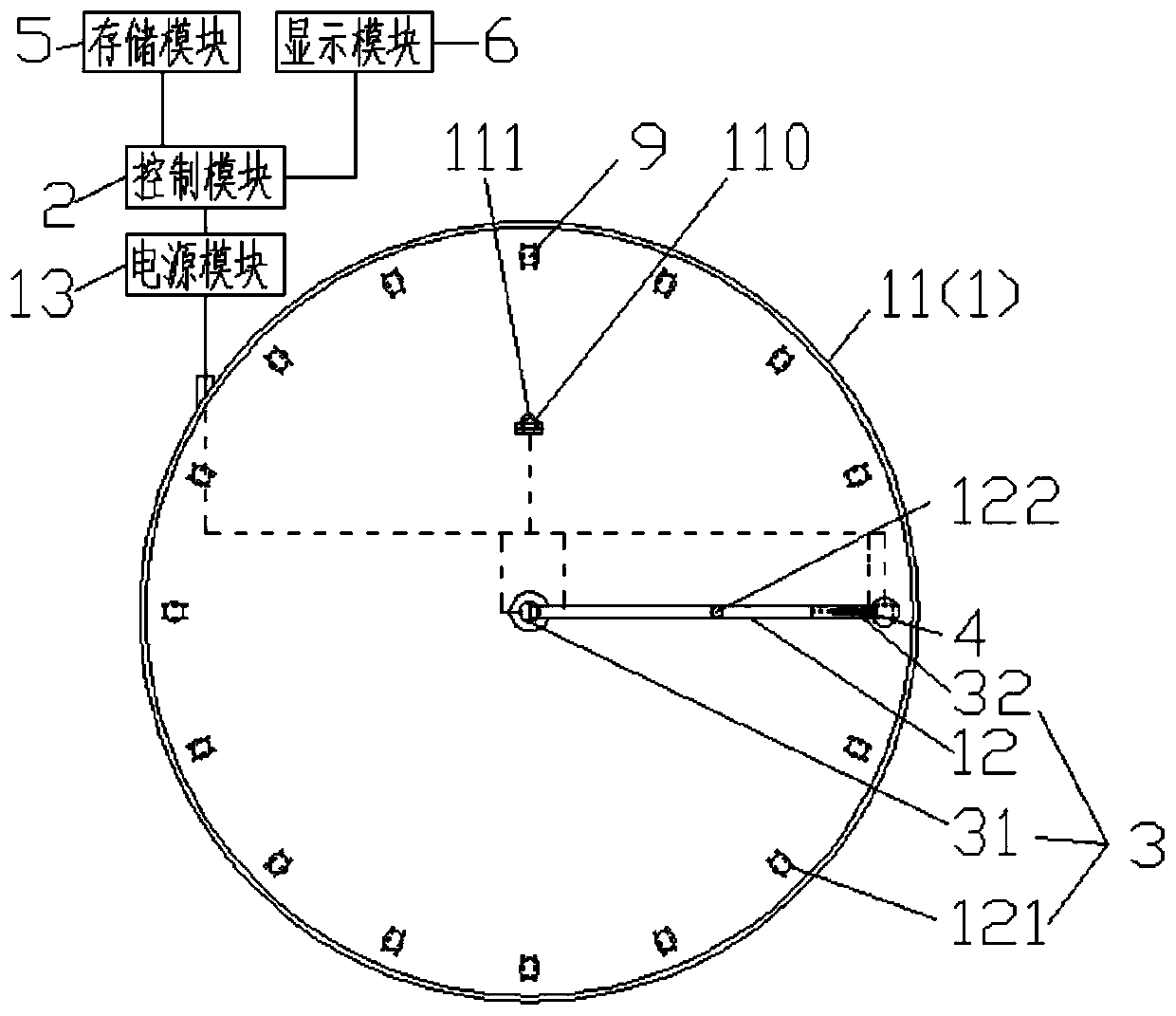

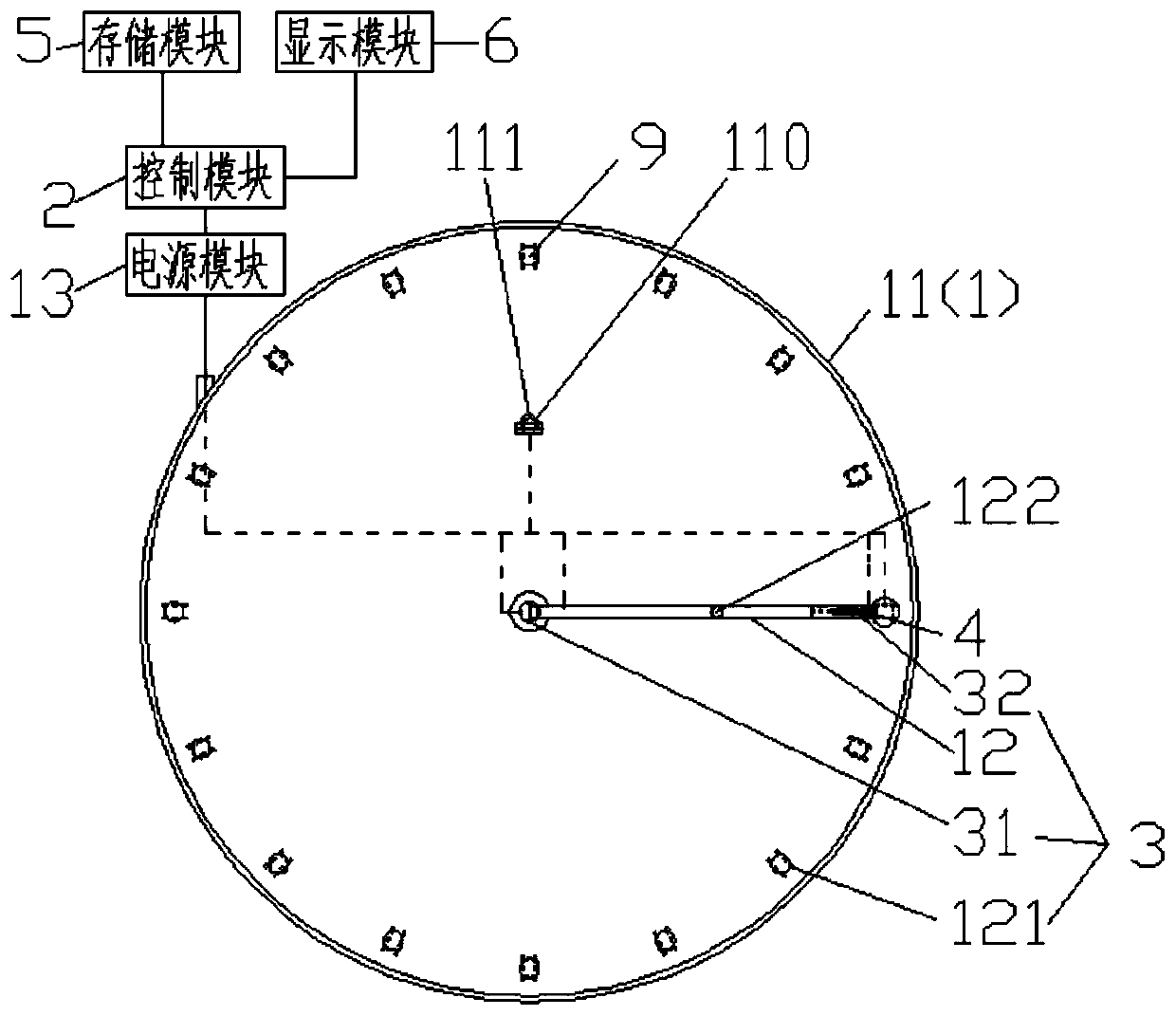

[0025] like figure 1 , an automatic collection system for LED characteristic parameters, which collects characteristic parameters of LED samples 9, including an LED test mechanism 1, a control module 2, an actuator 3, a detection module 4, a storage module 5, a display module 6, and a power supply module 13. The LED test mechanism 1 includes a test bench 11 placed horizontally, a mechanical arm 12 arranged on the test bench 11, and the power supply module 13 is an LED sample 9 and a control module 2, an actuator 3, a detection module 4, and a storage module. 5. The display module 6 supplies power, and the LED sample 9 is placed on the test bench 11. The test bench 11 is provided with a short-circuit mechanism 121 on the side of the LED sample 9, and the short-circuit mechanism 121 is suitable for short-circuiting the LED. catch. The control module 2 is a PLC or a single-chip microcomputer; the LED testing mechanism 1 can be controlled independently or combined with other test...

Embodiment 2

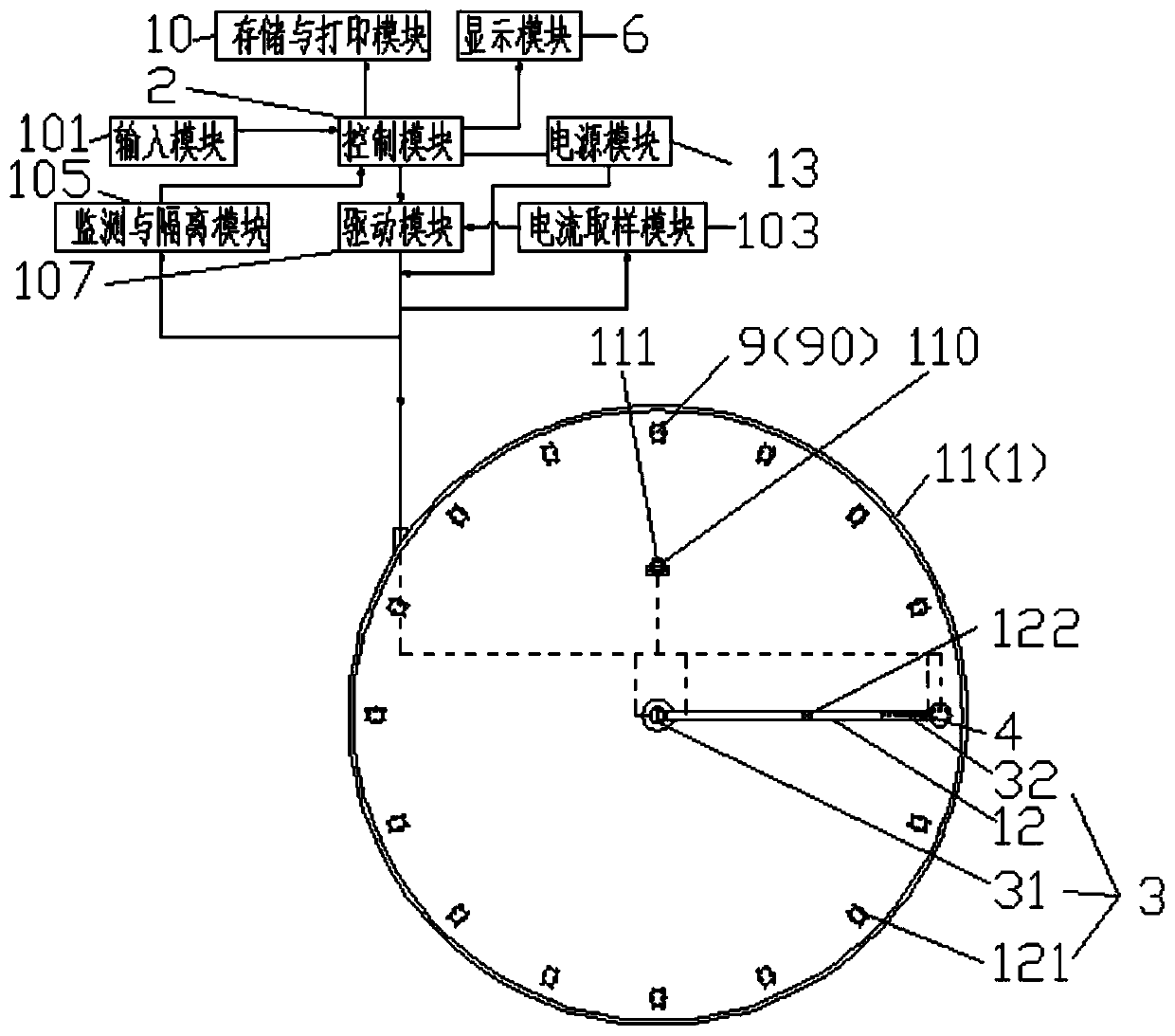

[0032] like figure 2 , Embodiment 2 On the basis of Embodiment 1, the following expansions are made:

[0033] The LED characteristic parameter automatic collection system is integrated in the LED test automatic control system, and the automatic control system conducts a power-on test on a group of LED samples connected in series, and outputs the test current, preferably using a programmable constant current source to output the test current; When a failed sample appears in a group of LED samples, the failed sample is automatically short-circuited, and the number and failure time of the failed sample are recorded until the test cut-off condition is reached. This scheme can automatically short-circuit the failed samples and restore the test, which is convenient and reliable.

[0034] Specifically, in addition to the LED test mechanism 1, control module 2, actuator 3, detection module 4, display module 6, and power module 13 mentioned in Embodiment 1, the LED test automatic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com