New-type wire for micro-unmanned aerial vehicle internal connection and preparation method thereof

An internal connection, drone technology, used in cable/conductor manufacturing, circuits, conductive materials, etc., can solve problems such as the inability to meet the needs of micro drones and the unsuitability of wires in special environments, to improve weather resistance performance, reduce The effect of body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

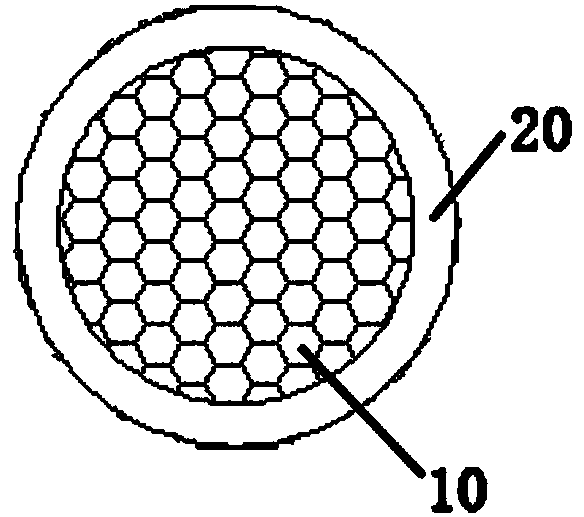

[0028] Such as figure 1 As shown, the new miniature drone provided by the present invention is connected with wires including a wire core composed of a copper wire conductor 10 and an insulating layer 20 covering the outside of the wire core; wherein the copper wire conductor 10 is preferably TR Type soft copper wire, the insulating layer 20 is made of high-density polyethylene material.

[0029] Preferably, the core is formed by twisting 40 TR-type soft copper wires, and the twisted pitch diameter ratio of the 40 TR-type soft copper wires, that is, the ratio of the pitch length to the outer diameter of the strands is not more than 8. , May be preferably 6.

[0030] Different from the existing general cables, the copper wire conductor 10 in the present invention adopts a thinner copper wire than the sixth type conductor. The diameter of the copper wire conductor 10 is not greater than 0.1 mm, preferably 0.08 mm; the length of the copper wire conductor 10 The rate may preferably be...

Embodiment 2

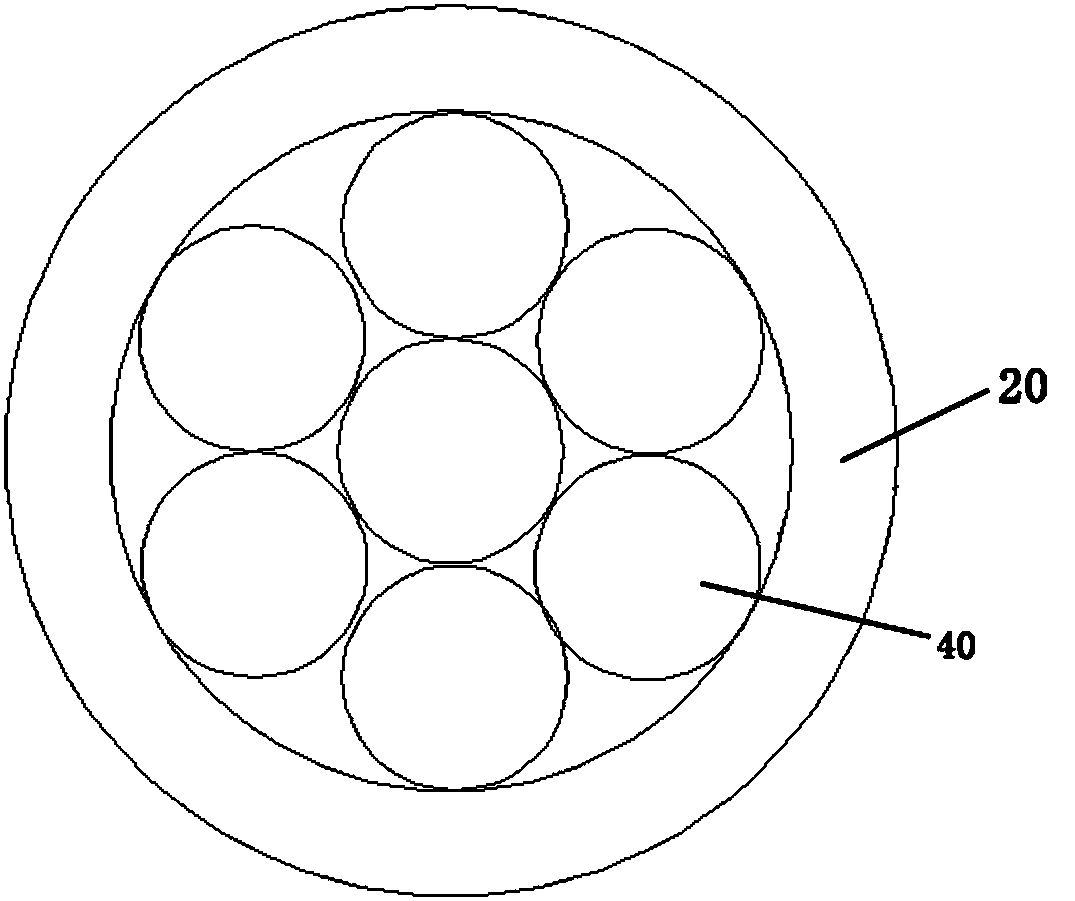

[0039] Such as image 3 As shown, the wire for internal connection of the novel micro-UAV provided in this embodiment has stronger bending resistance than the first embodiment. Specifically, the difference between this embodiment and the first embodiment is that the wire core is not directly twisted by 40 TR-type soft copper wires, but is first twisted into an intermediate conductor 40 from TR-type soft copper wires, and then the intermediate conductor 40 The wires are twisted directly into the core and twisted twice, so that the wire for internal connection of the micro-UAV provided in this embodiment has extremely strong bending resistance. fracture.

[0040] Specifically, each intermediate conductor 40 is formed by twisting a plurality of TR-type soft copper wires, and the stranding direction of the plurality of TR-type soft copper wires is leftward, and the plurality of TR-type soft copper wires are twisted. After twisting and twisting, a plurality of middle 40 is obtained. ...

Embodiment 3

[0047] Such as Figure 4 As shown, the wire for internal connection of the novel micro-drone provided in this embodiment has a larger cross-sectional area than the first embodiment, and is suitable for models with larger currents.

[0048] Specifically, the difference between this embodiment and the first embodiment is that the wire core adopts a composite stranding process structure. First, a plurality of copper wire conductors 10 are twisted into a plurality of inner core conductors 30 according to a certain twist pitch ratio, and the outer surface of each inner core conductor 30 is covered with tissue paper, and then a plurality of inner core conductors 30 The wire cores are twisted according to a certain stranded pitch diameter ratio. The stranded voids of each inner core conductor 30 can be filled with a filling layer. The filling layer can preferably be a flexible polyester-cotton fiber rope or a flexible The reinforcing ribs are made to make the stranded inner core conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com