A Control System of Synchronous Rectifier in llc Converter

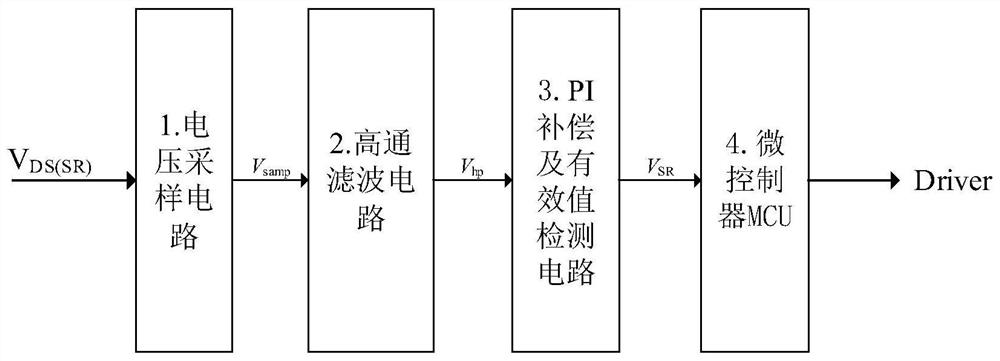

A technology of synchronous rectifier tube and control system, which is applied in control/regulation system, conversion of DC power input to DC power output, instrument, etc., can solve the detection deviation of sampling circuit or microcontroller, synchronous rectifier tube error control signal, acquisition The difficulty of the solution increases, so as to achieve the effect of accurate results, adaptive control, and the length of on-time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

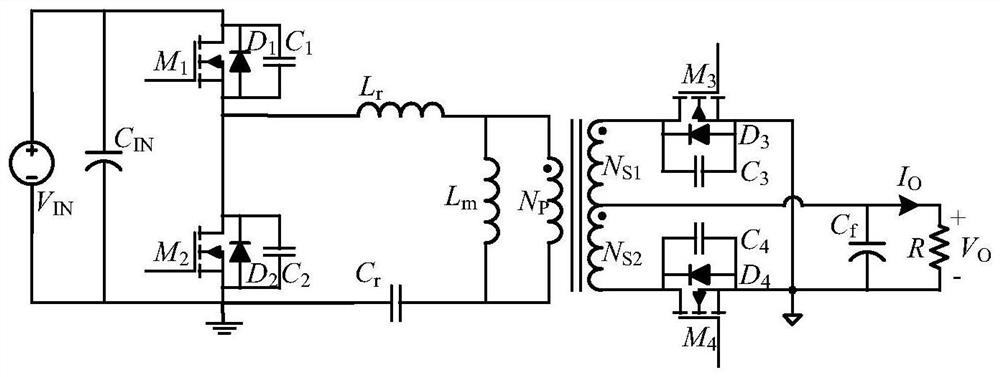

[0032] Such as figure 1 , the circuit components of the existing synchronous rectification LLC resonant converter include the power tube M on the primary side of the transformer 1 , M 2 , the resonant capacitor Cr, the resonant inductance Lr and the exciting inductance Lm, the synchronous rectifier tube M on the secondary side of the transformer 3 , M 4 , output capacitor Cf and load R, etc. Among them, D 1 、D 2 Respectively power tube M 1 , M 2 The parasitic diode, C 1 、C 2 M respectively 1 , M 2 The parasitic capacitance, D 3 、D 4 Respectively synchronous rectifier tube M 3 , M 4 The parasitic diode, C 3 、C 4 Respectively synchronous rectifier tube M 3 , M 4 of parasitic capacitance.

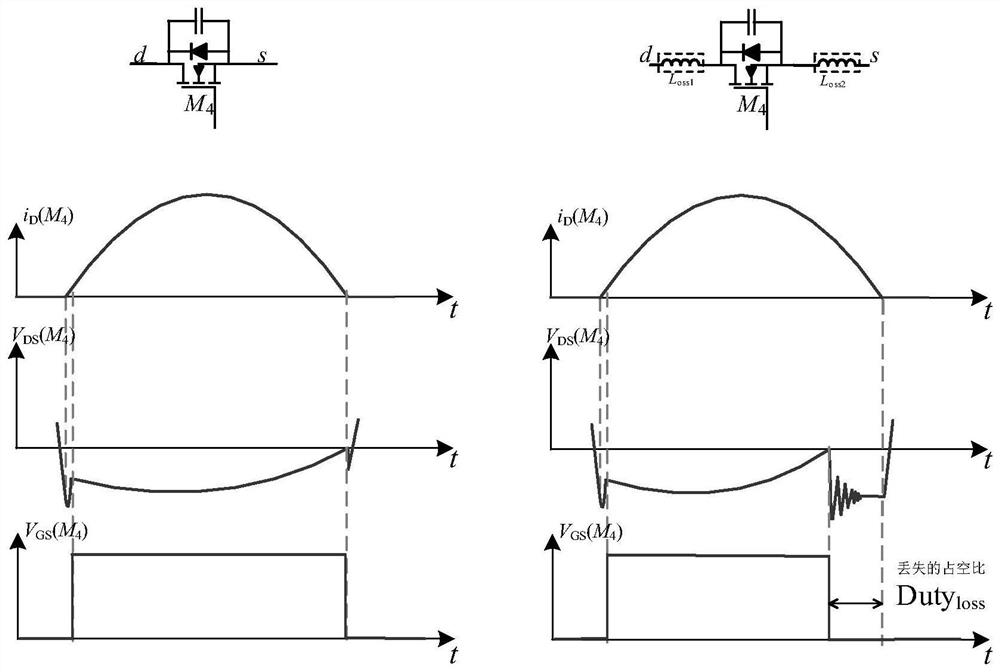

[0033] Such as figure 2 , when the LLC resonant converter operates at low frequency and high frequency, the effect of parasitic induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com