A method for recovering magnesium chloride and co-producing tetrahydrofuran from Grignard reaction waste residue

A technology of tetrahydrofuran and Grignard reaction, applied in magnesium chloride, magnesium halide, organic chemistry and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

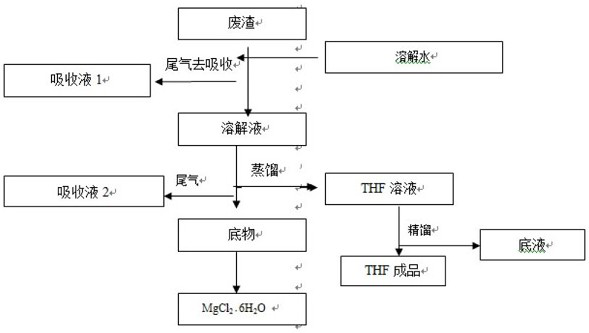

Method used

Image

Examples

Embodiment 1

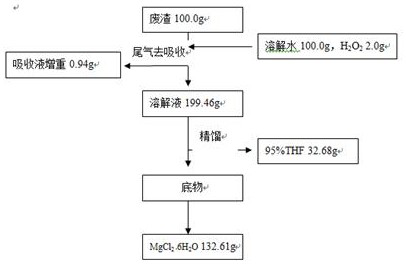

[0025] Embodiment 1: carry out experiment as follows:

[0026] 1) Dissolving: In pass N 2 Under the condition of protection, the complex waste residue is added to the dissolving water at a rate of 10-100kg / min, and a small amount of hydrogen peroxide is added to the dissolving water to oxidize trimethylphosphorus into stable trimethylphosphine. The fully reacted trimethylphosphorus can be oxidized and absorbed by entering the tail gas spray absorption device with nitrogen; the rate of waste residue feeding is controlled during the dissolution process, and at the same time, circulating water is passed outside the dissolution kettle to cool down, and the dissolution temperature is controlled below 40°C;

[0027] 2) Recovery of tetrahydrofuran by rectification: The dissolved material is rectified to recover tetrahydrofuran. During rectification, the liquid phase temperature is 68-75 °C and the material starts to boil, and the gas phase temperature is 62-63 °C to collect fractions...

Embodiment 2

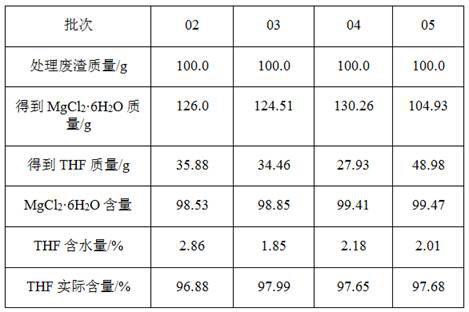

[0031] Three batches of experiments were carried out using the above steps, and the experimental results are as follows:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com