Preparation method of high-quality agar

A high-quality, agar technology, applied in the fields of biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of many raw materials, cumbersome process, long time consumption, etc., and achieve the effect of less reagents, simple process, and improved transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of preparation method of high-quality agar, comprises the steps:

[0068] (1) Weigh 10g of agar powder and add 100mL of 25% ethanol solution;

[0069] (2) Add 3 g of glutaric anhydride dissolved in 45 mL of absolute ethanol dropwise for esterification, and stir at 30°C while adding dropwise;

[0070] (3) Control the dropwise addition of glutaric anhydride within 1 hour, and use 3wt% NaOH solution to adjust the pH of the reaction system within 8.0-8.5 during the reaction process;

[0071] (4) After continuing to react for 0.5h, filter immediately, wash with deionized water, dry, pulverize and sieve to obtain high-quality glutaric anhydride-modified agar.

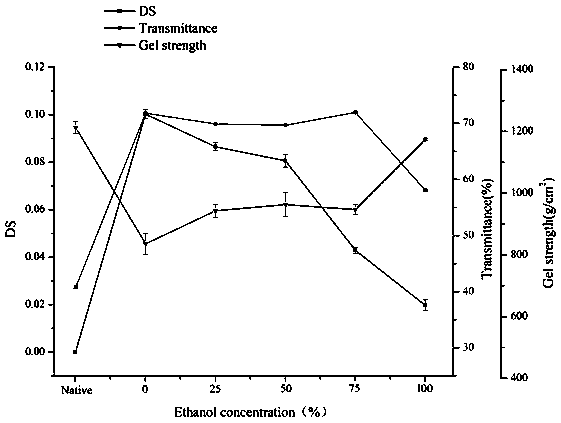

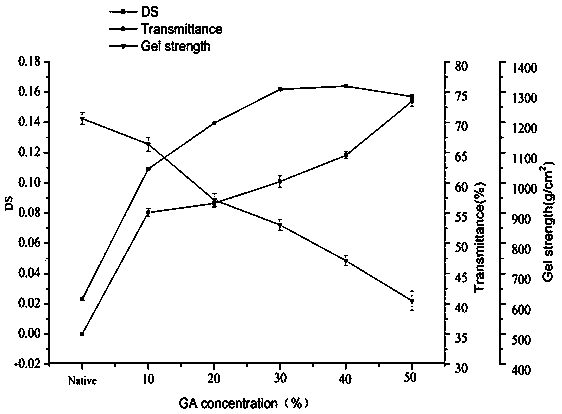

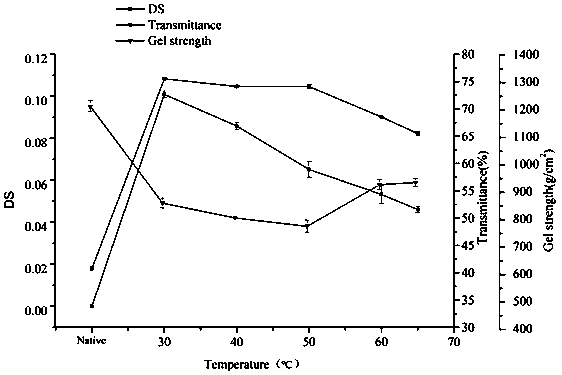

[0072] According to the above optimization results, the obtained high-quality agar has a degree of substitution of 0.1009, a transparency of 75.53%, which is 85% higher than that of the original agar at 40.8%, and a gel strength of 861 g / cm 2 , compared with the original agar 1213.4 g / cm 2 29.04% lower, but s...

Embodiment 2

[0080] The application of high-quality agar as emulsifier comprises the following steps:

[0081] (1) Take 0.45g of high-quality glutaric anhydride-modified agar and original agar respectively, add 30 mL of water, and microwave to dissolve;

[0082] (2) Place the agar solution in a 75°C water bath for 10 minutes;

[0083] (3) Add 1mL soybean oil and perform high-speed shearing for 3 minutes to obtain an emulsion.

[0084] (4) For the prepared emulsion, use the spectrophotometer method to measure its emulsification and emulsification stability. The emulsification is glutaric anhydride modified agar: 0.151±0.026, original agar: 0.188±0.035, and the emulsification stability It has also been improved, indicating that the performance of modified agar as an emulsifier is improved compared with that of the original agar.

Embodiment 3

[0086] The application of high-quality agar as a biological medium (LB medium) includes the following steps:

[0087] (1) Preparation of medium: Weigh 1 g bacteriological peptone, 0.5 g yeast powder, and 1 g NaCl, then add modified agar and original agar accounting for 2% of the total system, add 100 ml of water, and use 1 mol / L The NaOH solution adjusted the pH to 7.5. Sterilize in a high temperature sterilizer for 21 min.

[0088] (2) After cooling the sterilized culture solution to about 60°C, pour it into a petri dish on an ultra-clean workbench. After solidification, Escherichia coli was inoculated by the plate streak method.

[0089] (3) After completing the above steps, place the culture dish in a 37°C incubator for 24 hours. Observe its growth status.

[0090] (4) pass Figure 9 It shows that the modified agar medium is more transparent than the original agar, which is more conducive to observing the growth of the colony.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com