Three-layer EVA and PO composite photovoltaic film with high reliability and high gain and preparation method of composite photovoltaic film

A high-gain, composite light technology, used in photovoltaic power generation, non-polymer adhesive additives, adhesives, etc., can solve the problems of low peel strength, reliability impact, low reflectivity, etc., to improve the diffuse reflection effect, components Power boost, good reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

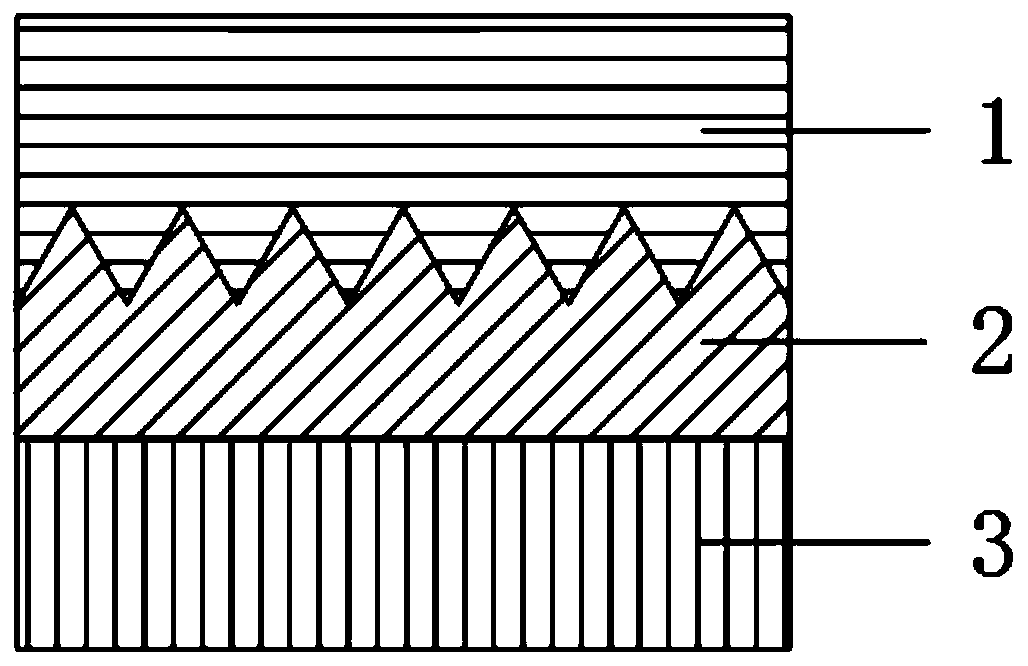

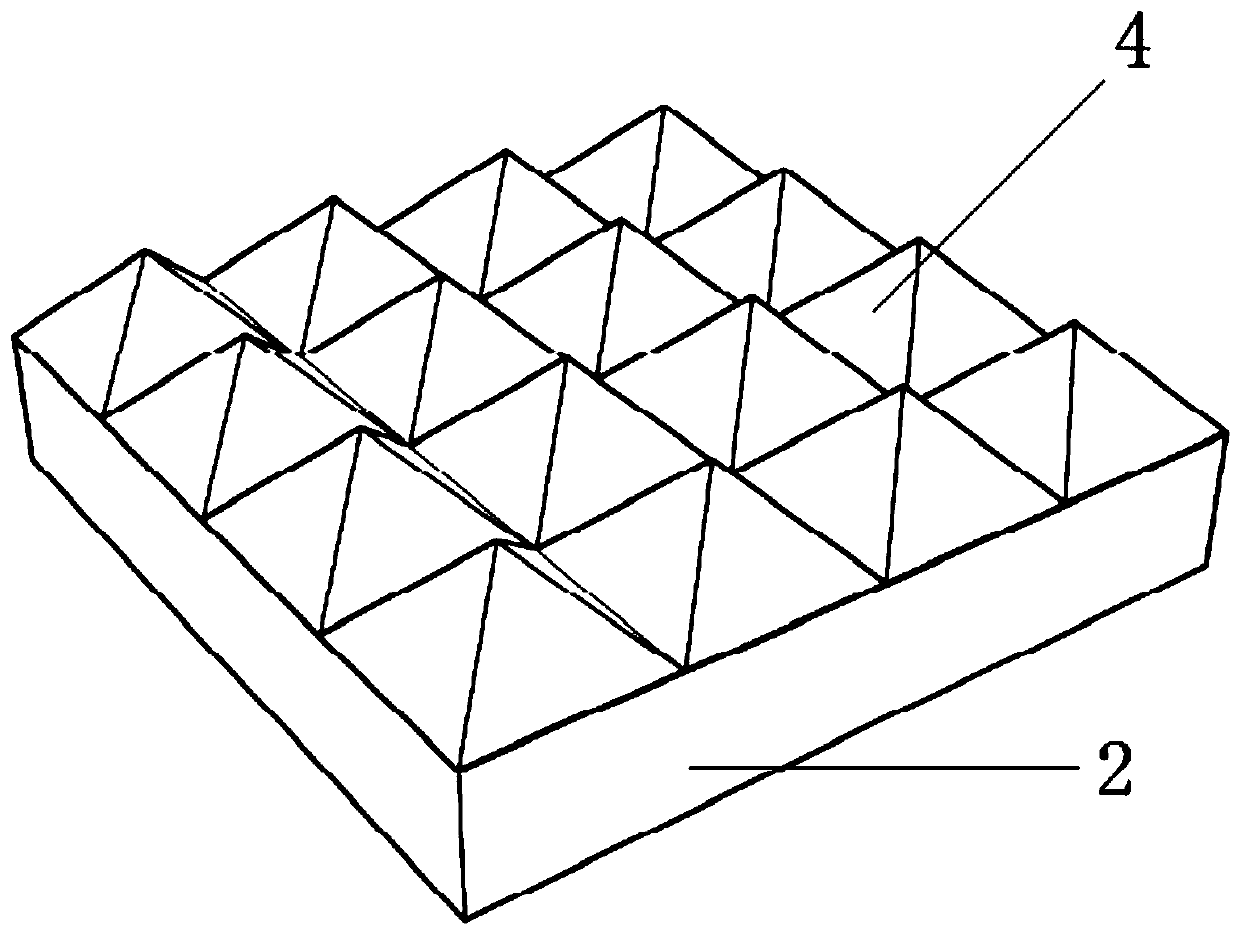

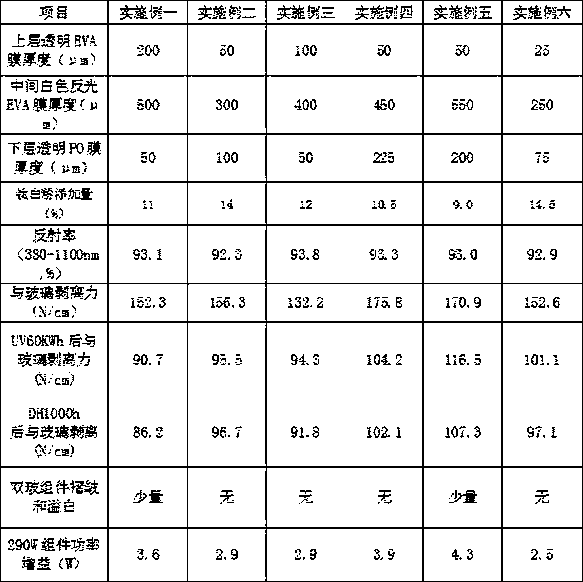

[0041] like figure 1 and figure 2 Shown, the preparation method of a kind of three-layer high reliable high-gain EVA of the present invention and PO composite photovoltaic adhesive film is made of upper transparent EVA layer, middle white reflective EVA layer and lower transparent PO layer; described upper transparent EVA layer is The transparent EVA casting composite layer has a thickness of 25-150 μm; the middle white EVA reflective layer is provided with a pyramid-shaped reflective structure 4, and the thickness is 250-550 μm; the lower transparent PO layer is a transparent EVA casting composite co-extrusion layer, with a thickness of 50~225μm. The total thickness of the EVA photovoltaic adhesive film of the present invention is 350-800 μm.

[0042] Concrete implementation example raw materials and preparation steps are as follows: the first step intermediate white reflective EVA layer production process and formula design:

[0043] Main material: Ethylene-vinyl acetate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com