Ionic liquid loaded microencapsulated penicillium purpureum cell and preparation method and application thereof

A technology for producing Penicillium purpuricum and ionic liquid, which is applied in biochemical equipment and methods, microorganism-based methods, immobilized on or in inorganic carriers, etc. The effect of easy recovery and high biocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

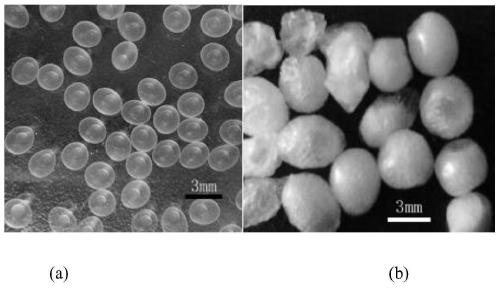

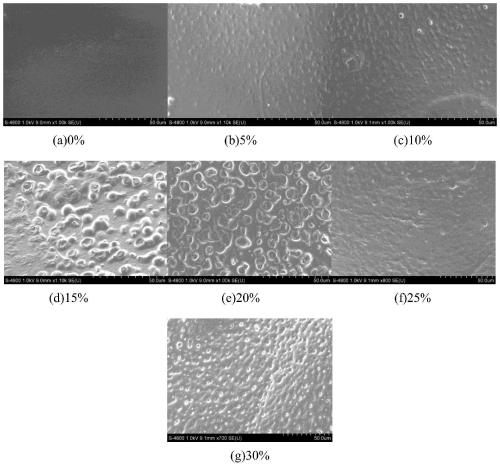

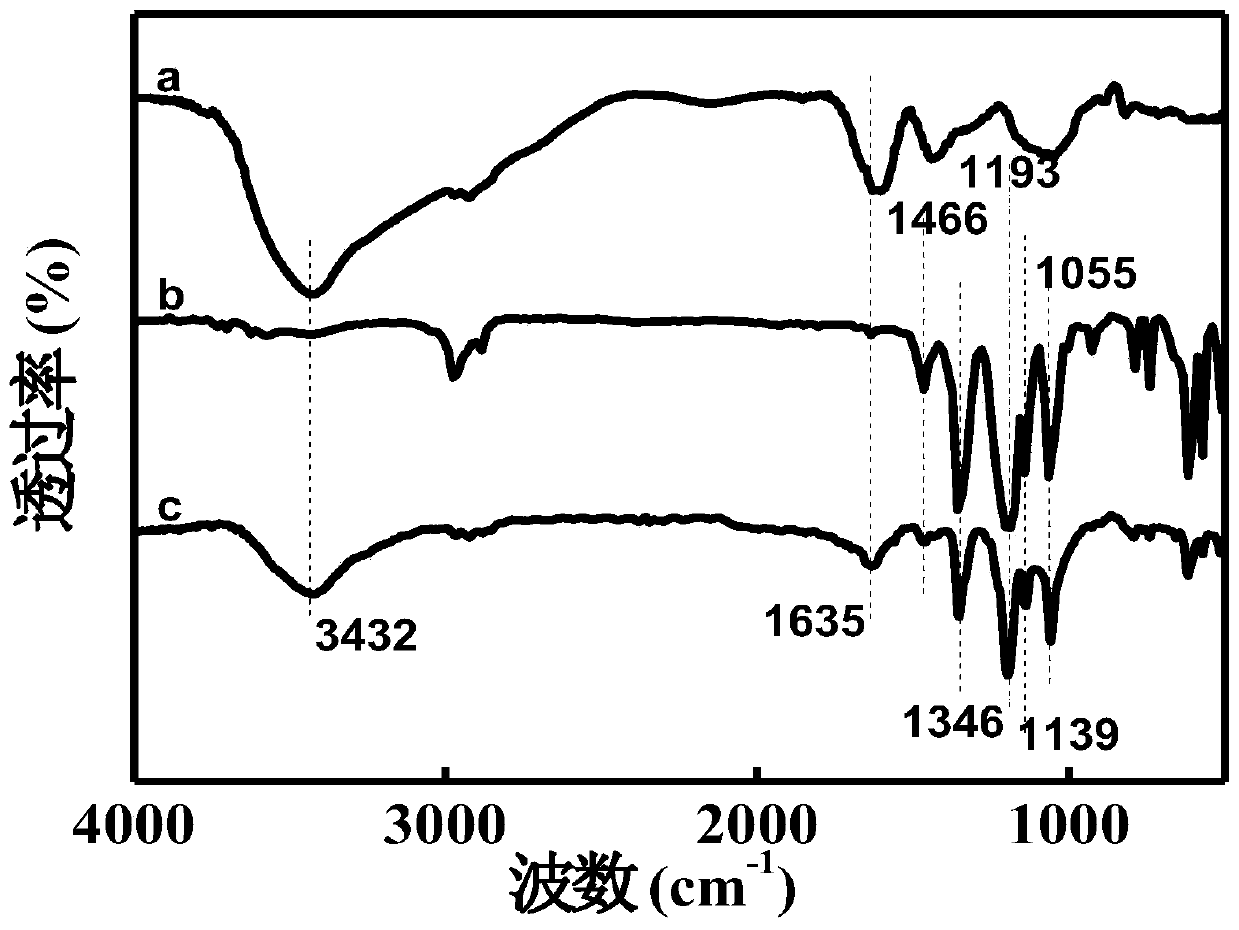

Embodiment 1

[0042] Prepare a solution of CMC (sodium carboxymethylcellulose) at a concentration of 1.4% w / v and a solution of CaCl at a concentration of 1.0% w / v 2 (Calcium chloride) mixed solution, sterilized by high-pressure steam at 121°C for 20 minutes, after the solution was naturally cooled to room temperature, 15% v / v of [MBPy]Tf irradiated by ultraviolet light was added under sterile conditions 2 N, magnetically stir the mixed solution until the ionic liquid is evenly dispersed in the solution, then add 3% v / v bacterial suspension (the strain is Penicillium purpurogenum CGMCC No.446), and magnetically stir evenly. The mixed solution was dripped into the 1.2% w / v SA (sodium alginate) solution by magnetic stirring (120r / min) at a constant speed through the peristaltic pump (120r / min), spherical microencapsulated cells appeared rapidly in the SA solution, and the dripping Stir for 5 minutes after the addition, then filter the SA solution with a sieve with a pore size of about 1mm, ri...

Embodiment 12

[0045] Prepare a solution of CMC (sodium carboxymethylcellulose) at a concentration of 1.0% w / v and a solution of CaCl at a concentration of 0.5% w / v 2 (Calcium chloride) mixed solution, sterilized by high-pressure steam at 121°C for 20min, after the solution was naturally cooled to room temperature, 5% v / v of [MBPy]Tf irradiated by ultraviolet light was added under sterile conditions 2 N, magnetically stir the mixed solution until the ionic liquid is evenly dispersed in the solution, then add 2% v / v bacterial suspension (the bacterial strain is Penicillium purpurogenum CGMCC No.446, and magnetically stir evenly. The mixed solution is passed through Peristaltic pump (120r / min) drips into 0.6% w / v SA (sodium alginate) solution with magnetic stirring (120r / min) at a constant speed, spherical microencapsulated cells appear rapidly in the SA solution, stir after the addition 5min, then filter the SA solution with a sieve with a pore size of about 1 mm, rinse the formed microencaps...

Embodiment 13

[0047] Prepare a solution of CMC (sodium carboxymethylcellulose) at a concentration of 1.8% w / v and a solution of CaCl at a concentration of 0.25% w / v 2 (Calcium chloride) mixed solution, sterilized by high-pressure steam at 121°C for 20min, after the solution was naturally cooled to room temperature, 30% v / v of [MBPy]Tf irradiated by ultraviolet light was added under sterile conditions 2 N, magnetically stir the mixed solution until the ionic liquid is uniformly dispersed in the solution, then add 6% v / v bacterial suspension (bacterial strain is Penicillium purpurogenum (Penicillium purpurogenum) CGMCC No.446, and magnetically stir evenly. This mixed solution is passed through Peristaltic pump (120r / min) drips into 1.4% w / v SA (sodium alginate) solution with magnetic stirring (120r / min) at a constant speed, spherical microencapsulated cells appear rapidly in the SA solution, stir after the addition 5min, then filter the SA solution with a sieve with a pore size of about 1 mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com