Preparation method and applications of neutral red-modified polyacrylic acid hydrogel mediator functional material

A technology of hydrogel mediator and polyacrylic acid, which is applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc. It can solve the problems of low yield and achieve good biocompatibility and excellent swelling performance and hydrophilic properties, and the effect of increasing the loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

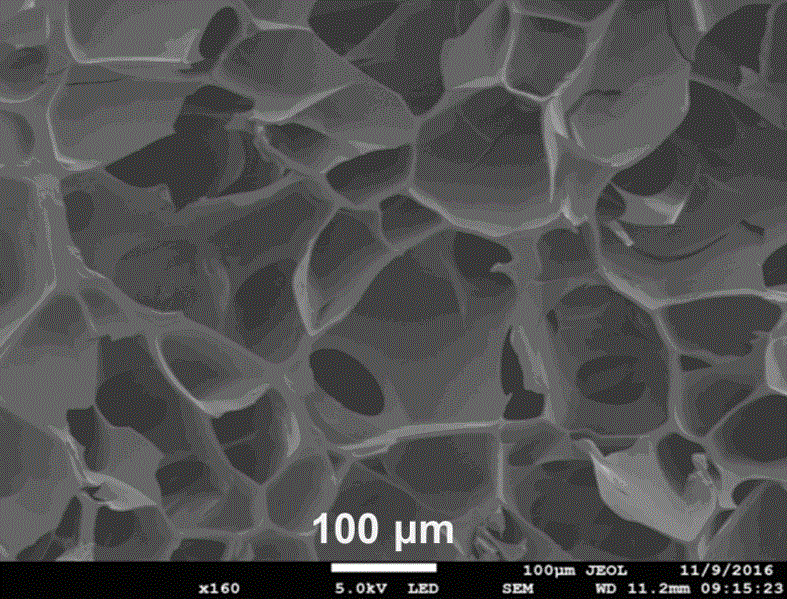

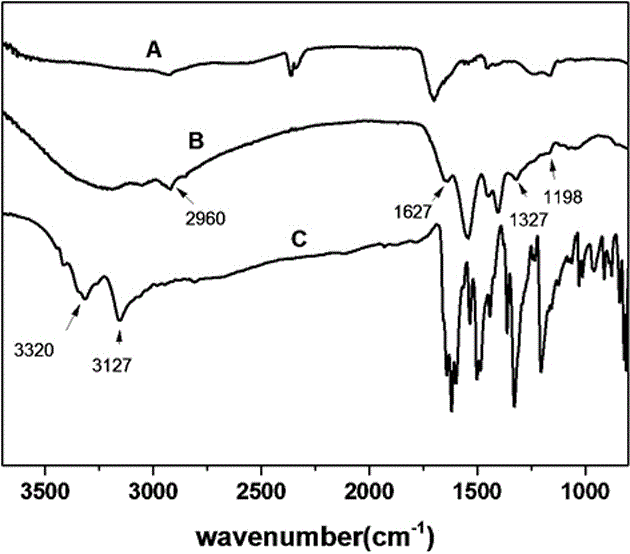

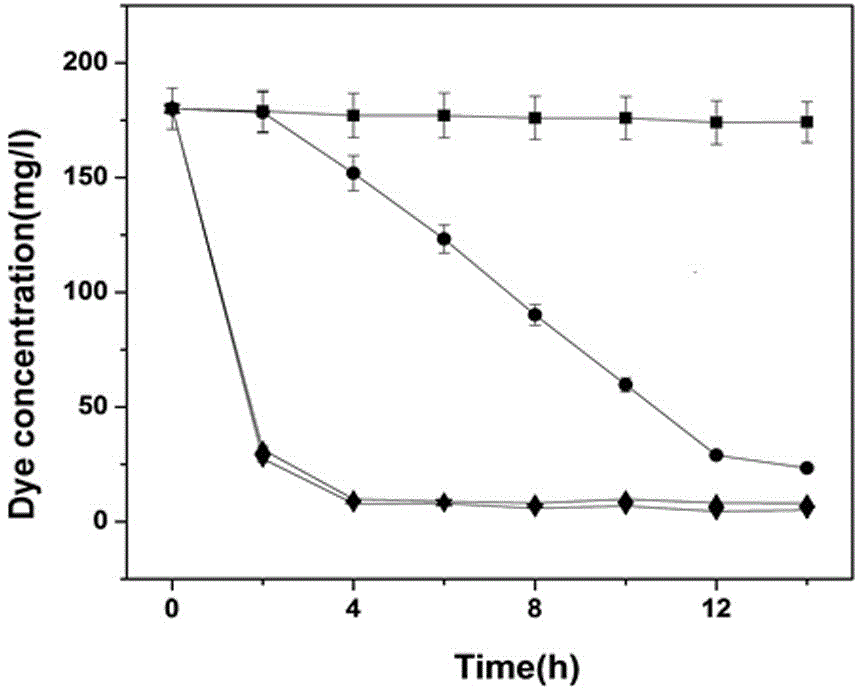

[0018] Dissolve 1.5 g of acrylic acid, 0.062 g of N,N-methylenebisacrylamide and 0.05 g of potassium persulfate in a mixture of 2 mL of ethanol and 17 mL of distilled water, heat in a water bath to 60°C, and stir mechanically until a hydrogel is formed. Its hydrogelation time is 20min, and the hydrogel swelling rate is 22.29.

[0019] Neutral red was branched on polyacrylic acid hydrogel through EDC condensation reaction. The specific operation steps are as follows: 400 mgEDC . HCl, 500 mg NHS and 500 mg neutral red were dissolved in 100 mL of distilled water to prepare a reaction solution, the gel was cut into small cubes and immersed in the reaction solution, and reacted at room temperature for 24 h. The reacted gel was washed three times with distilled water, soaked in distilled water, and the distilled water was replaced every 4 h until the distilled water was colorless and transparent, and continued to soak for 24 h to obtain the NR-PAaH functional material. The graftin...

Embodiment 2

[0027] Dissolve 1.5 g of acrylic acid, 0.09 g of N,N-methylenebisacrylamide and 0.05 g of potassium persulfate in a mixture of 2 mL of ethanol and 17 mL of distilled water, heat in a water bath to 50 °C, and stir mechanically until a hydrogel is formed. The gelation time of the hydrogel was 8 minutes, and the swelling ratio of the hydrogel was 24.18.

[0028] Neutral red was branched on polyacrylic acid hydrogel through EDC condensation reaction. The specific operation steps are as follows: 400 mgEDC . HCl, 500 mg NHS and 500 mg neutral red were dissolved in 100 mL of distilled water to prepare a reaction solution, the gel was cut into small cubes and placed in the reaction solution, and reacted at room temperature for 24 h. The reacted gel was washed three times with distilled water, soaked in distilled water, and the distilled water was replaced every 4 h until the distilled water was colorless and transparent, and continued to soak for 24 h to obtain the NR-PAaH functional...

Embodiment 3

[0034] Dissolve 1.5 g of acrylic acid, 0.062 g of N,N-methylenebisacrylamide and 0.05 g of sodium persulfate in a mixture of 2 mL of ethanol and 17 mL of distilled water, heat in a water bath to 50 °C, and stir mechanically until a hydrogel is formed. The gelation time of the hydrogel was 20 minutes, and the swelling rate of the hydrogel was 22.29.

[0035] Neutral red was branched on polyacrylic acid hydrogel through EDC condensation reaction. The specific operation steps are as follows: 400 mgEDC . HCl, 400 mg NHS and 500 mg neutral red were dissolved in 100 mL of distilled water to prepare a reaction solution, the gel was cut into small cubes and placed in the reaction solution, and reacted at room temperature for 24 h. Wash the reacted gel three times with distilled water, soak it in distilled water, and replace the distilled water every 4 hours until the distilled water is colorless and transparent, so that the neutral red adsorbed on the hydrogel can be washed off, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting amount | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com