Underfloor heating floor with rapid heating function and production process of underfloor heating floor

A geothermal floor and fast technology, which is applied in the field of geothermal floor, can solve the problems of slow heat conduction speed, uneven temperature distribution, and slow floor heating speed of geothermal floor, so as to reduce usage, prevent water seepage, and increase heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

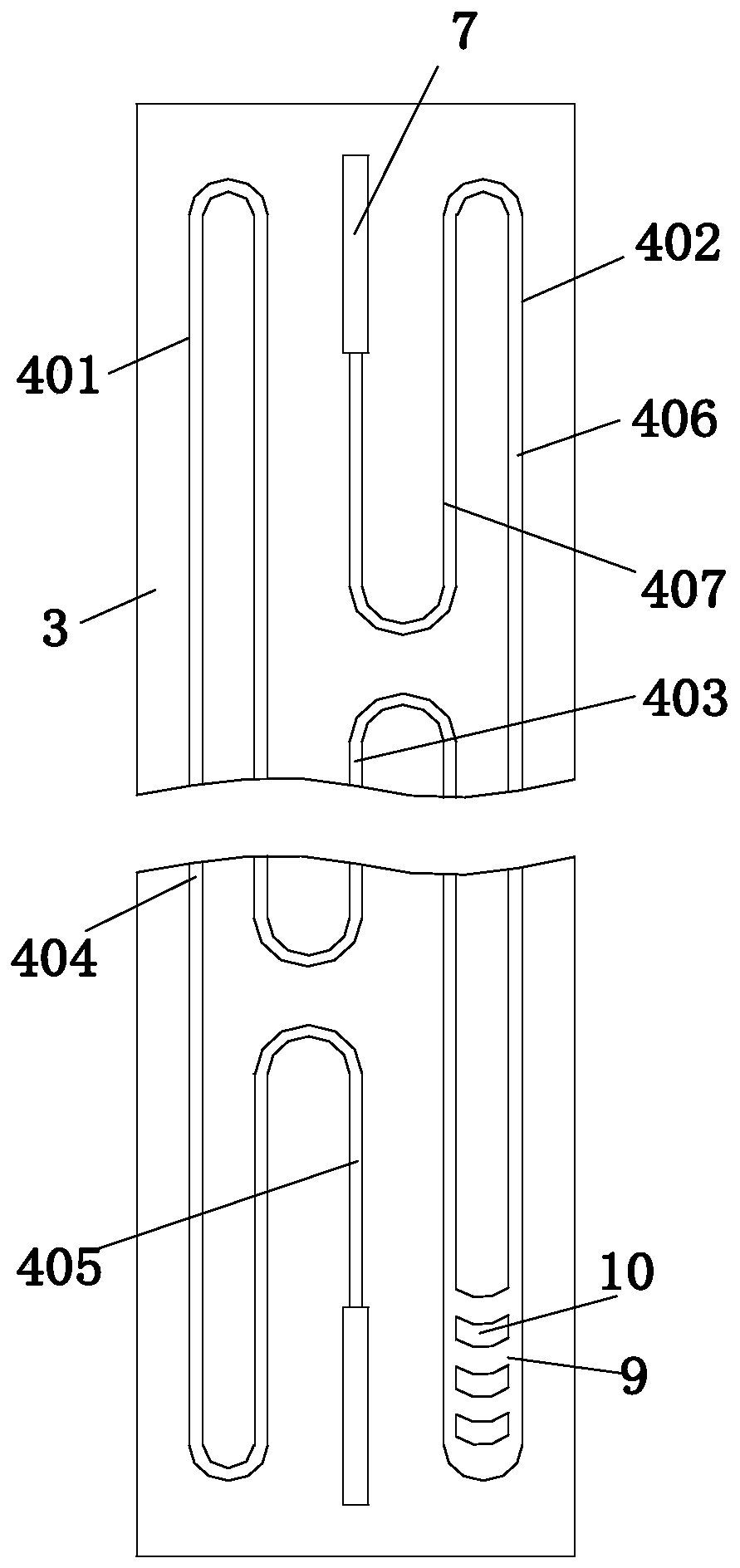

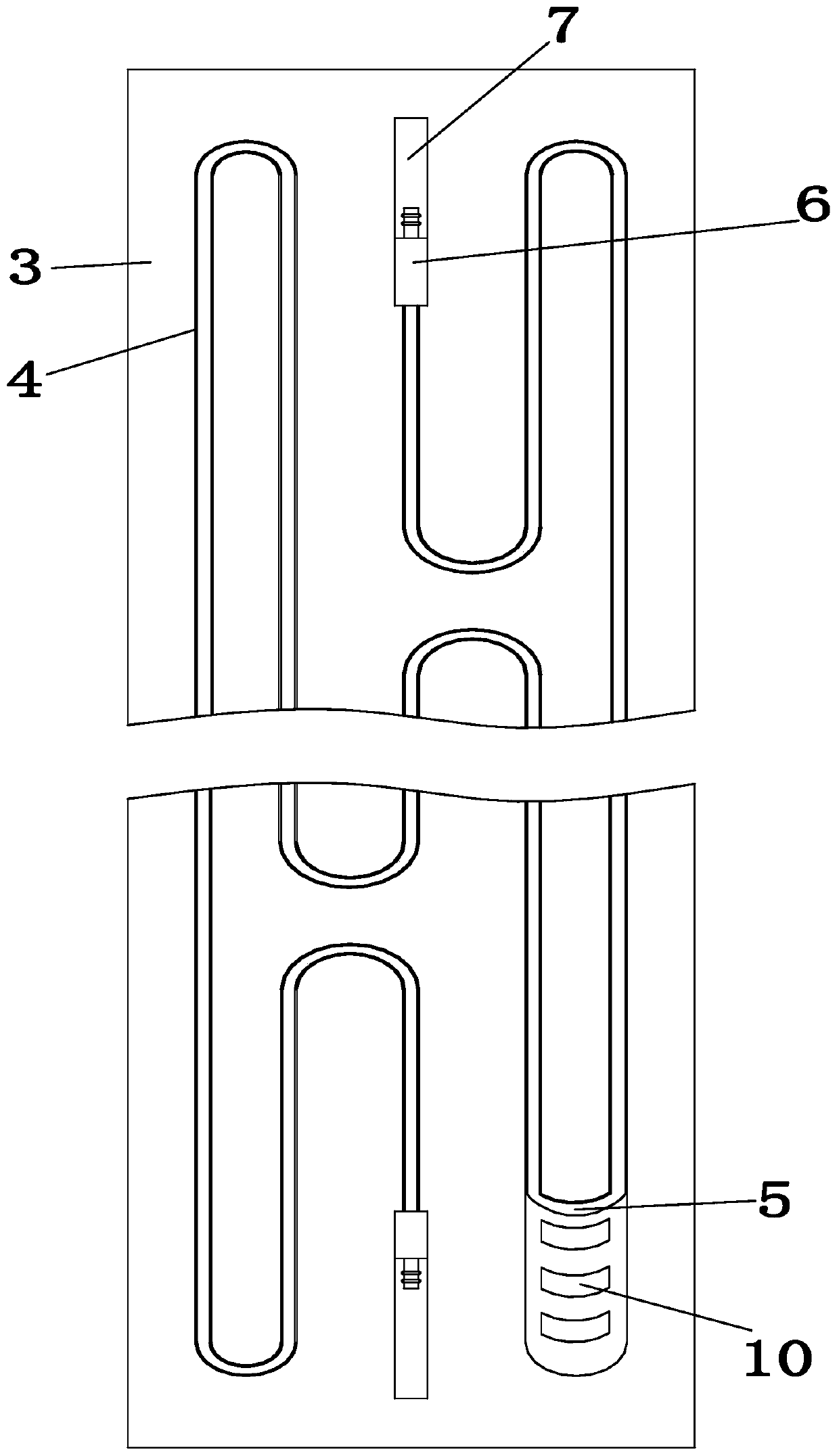

[0030] Example. A geothermal floor that heats up quickly, the specific structure is as follows Figure 1 to Figure 11 As shown, a substrate 1 is included, and a panel 2 is arranged above the substrate 1; the substrate 1 includes a board body 3, and a wire groove 4 is provided on the upper surface of the board body 3, and a heating cable 5 is arranged in the wire groove 4; the substrate 1 and the panel The thickness ratio between 2 is 1:2-1:3.

[0031] Both ends of the heating cable 5 are provided with lugs 6 , and the two ends of the trunking 4 are provided with openings for placing the ends 7 .

[0032] The terminal block 6 is also connected with a terminal block 8; the terminal block 6 includes a female connection head 601, one end of the female connection head 601 is connected to the heating ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com