Dust collector motor deceleration method

A vacuum cleaner and motor controller technology, applied in the direction of a single motor speed/torque control, collectors, electric vehicles, etc., can solve the problem of long deceleration time, and achieve the effect of increasing the use time, improving the user experience, and shortening the deceleration time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

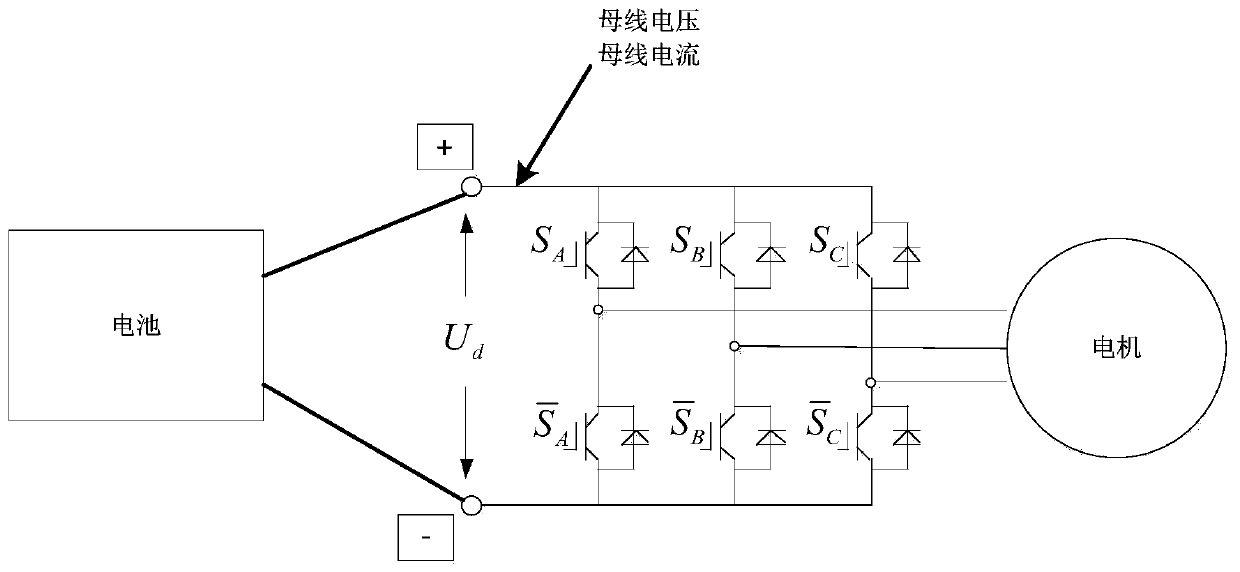

[0023] Such as figure 1 Shown is a schematic diagram of the inverter part of a vacuum cleaner motor controller of the present invention, including a three-phase permanent magnet synchronous motor, a power supply battery and a motor controller, and the single-chip microcomputer on the motor controller controls 6 switching tubes to switch regularly. The motor runs. The "bus voltage" and "bus current" of the motor controller are equal to the voltage and current of the battery.

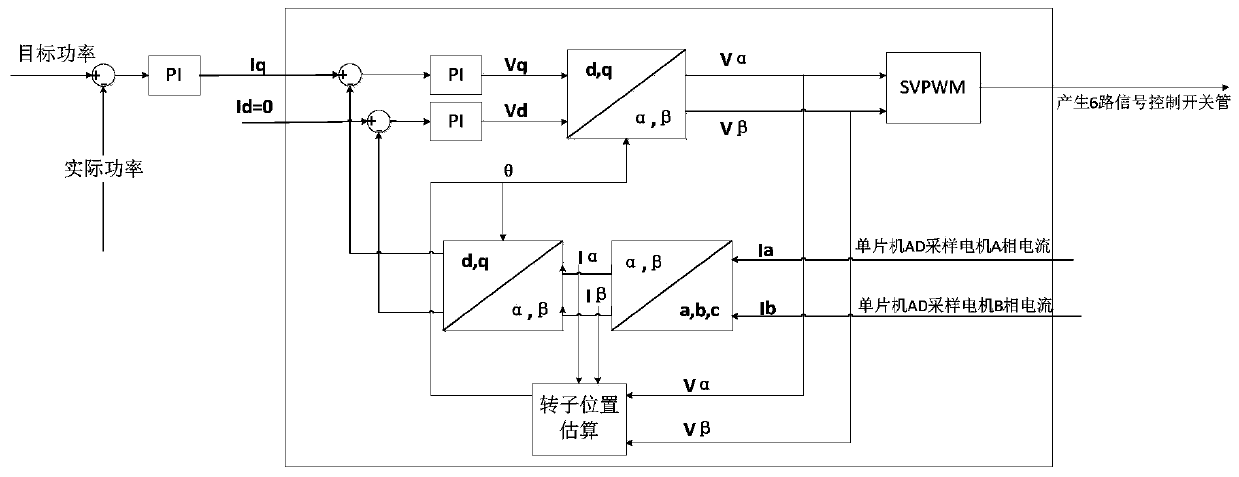

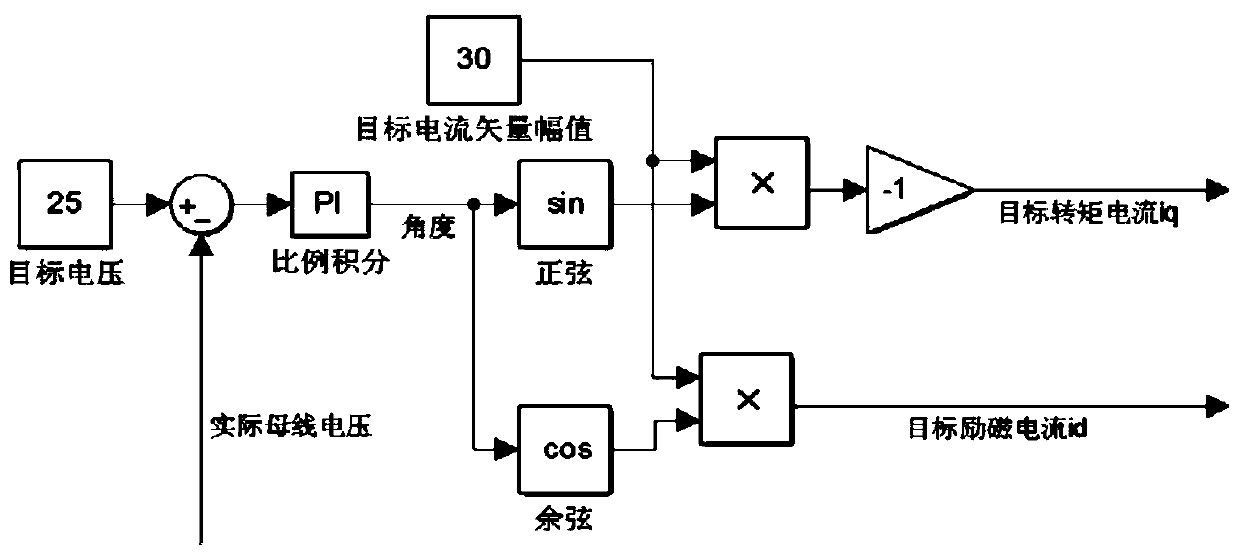

[0024] Such as figure 2 Shown is the vector control algorithm when the motor is running normally, and this algorithm is common. The input to the algorithm is the target torque current i d and the targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com