Sour and sweet taste composite reconstituted tobacco leaf and preparation method and application thereof

A technology for reconstituting tobacco leaves and sweetness, applied in the application, preparation of tobacco, tobacco and other directions, can solve the difficulty in directly blending solid characteristic flavors, reduce the smoking experience of consumers, and limit the development of characteristic flavors. It can reduce the dryness and irritation, the sensory design space is large, and the structure is novel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

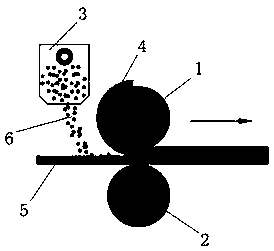

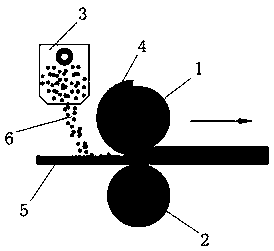

[0038] Such as figure 1 As shown, the device of the present invention comprises an upper drum 1, a lower drum 2 and a screw metering device 3 arranged on one side of the upper drum 1 and the lower drum 2.

[0039] Based on the above-mentioned device, the composite reconstituted tobacco leaf with a sweet and sour taste in this embodiment consists of a continuous upper and lower layer of papermaking tobacco leaf base as the sea phase, and a sour and sweet taste evenly dispersed between the two layers of the base as the island phase. Sensitive function complex composition.

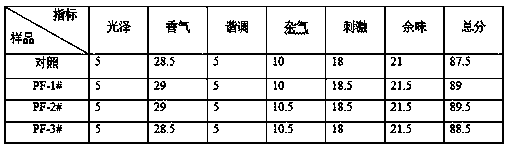

[0040] The sour-sweet functional compound of this embodiment is a compound powder of sour plum powder: neohesperidin dihydrochalcone: tangerine peel powder=5:3:2.

[0041] The preparation method of the sweet and sour taste compound of the present embodiment comprises the following steps:

[0042] Dried sour plum and tangerine peel until the water content is 5-8%, then using a swing type high-speed tradition...

Embodiment 2

[0052] In the compound reconstituted tobacco leaves with a sweet and sour taste in this embodiment, the sweet and sour functional compound is a compound powder of sour plum powder: glycyrrhizin: tangerine peel powder: Zimbabwe tobacco leaf powder = 3:3:2:2.

[0053] Wherein, the preparation method of the compound with sweet and sour taste comprises the following steps:

[0054] Dried sour plum, tangerine peel and Zimbabwean tobacco leaves to a moisture content of 5-8%, then crushed the natural plant materials with a swing-type high-speed traditional Chinese medicine grinder, and sieved them with a 50-mesh standard filter screen and a 200-mesh standard filter screen respectively Divided to obtain sour plum powder, tangerine peel powder and Zimbabwean tobacco leaf powder with a particle size of 50-200 meshes, and then compounded according to the mass ratio of sour plum powder: glycyrrhizin: tangerine peel powder: Zimbabwean tobacco leaf powder=3:3:2:2 Stir evenly to prepare the ...

Embodiment 3

[0063] In the compound reconstituted tobacco leaves with a sweet and sour taste in this embodiment, the functional compound with a sweet and sour taste is a compound powder of jujube powder: sour papaya powder: steviol glycoside: licorice powder = 4:3:2:1.

[0064] Wherein, the preparation method of the compound with sweet and sour taste comprises the following steps:

[0065] Dry jujube, sour papaya and licorice to a moisture content of 5-8%, then use a swing-type high-speed traditional Chinese medicine grinder to crush the natural plant materials, and sieve them with a 50-mesh standard filter screen and a 200-mesh standard filter screen respectively , to obtain the particle size is 50-200 purpose wild jujube powder, sour papaya powder and licorice powder, then according to the mass ratio of wild jujube powder: sour papaya powder: steviol glycoside: licorice powder = 4:3:2:1 compound and stir evenly, namely A compound with sour-sweet taste function required for preparing reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com