Numerical control deep hole keyway milling machine

A keyway milling machine and deep hole technology, applied to milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of increasing the labor intensity of the staff, it is difficult to ensure the consistency of multi-section groove lines, and it is difficult to ensure the accuracy of the keyway, etc., to achieve The effect of increasing the size of the cantilever, reducing the volume and ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

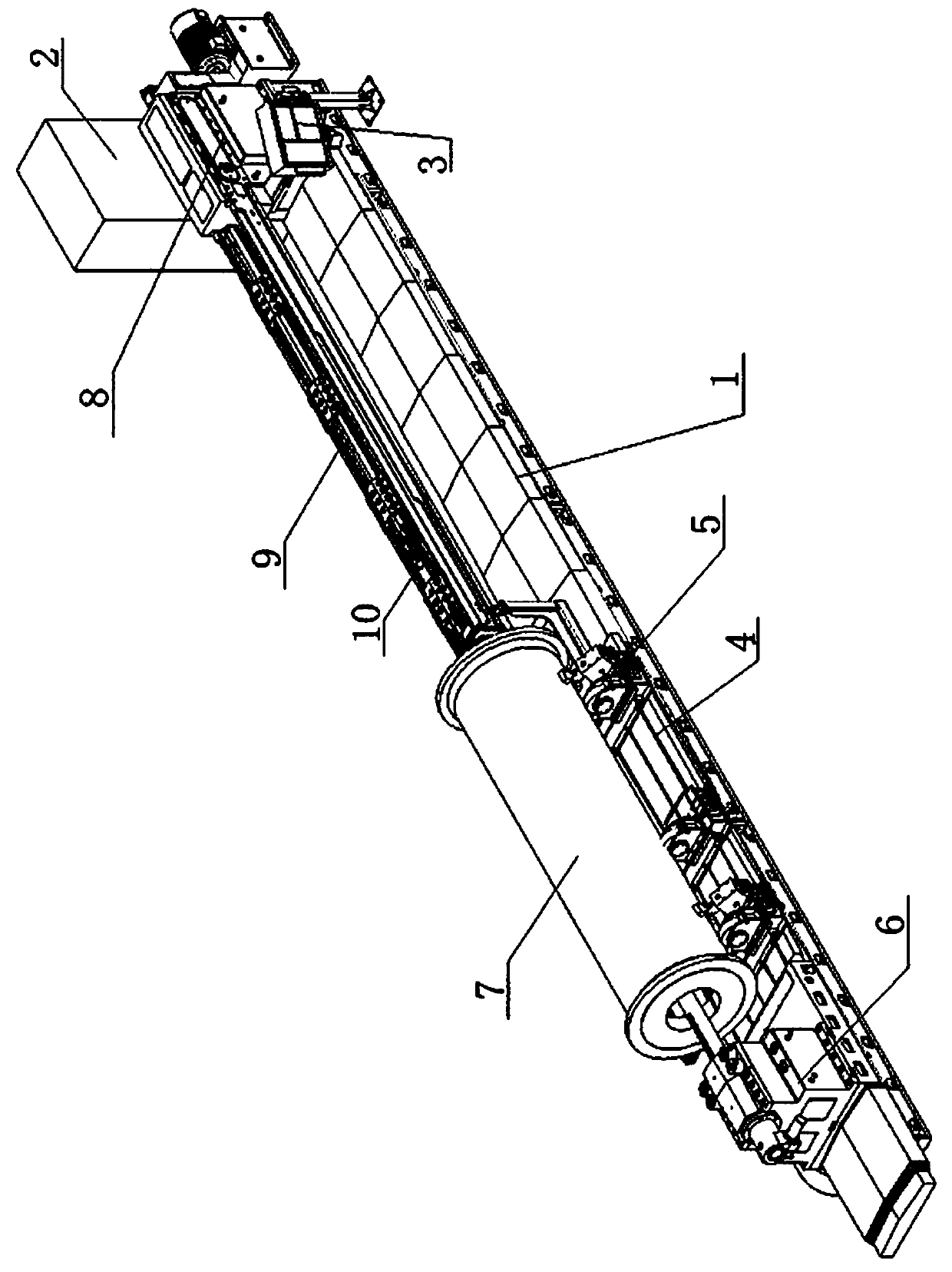

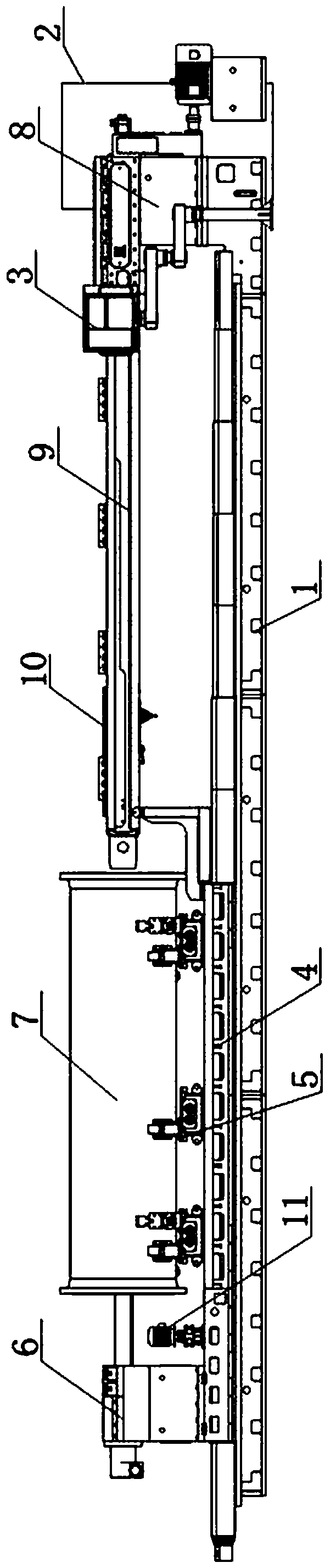

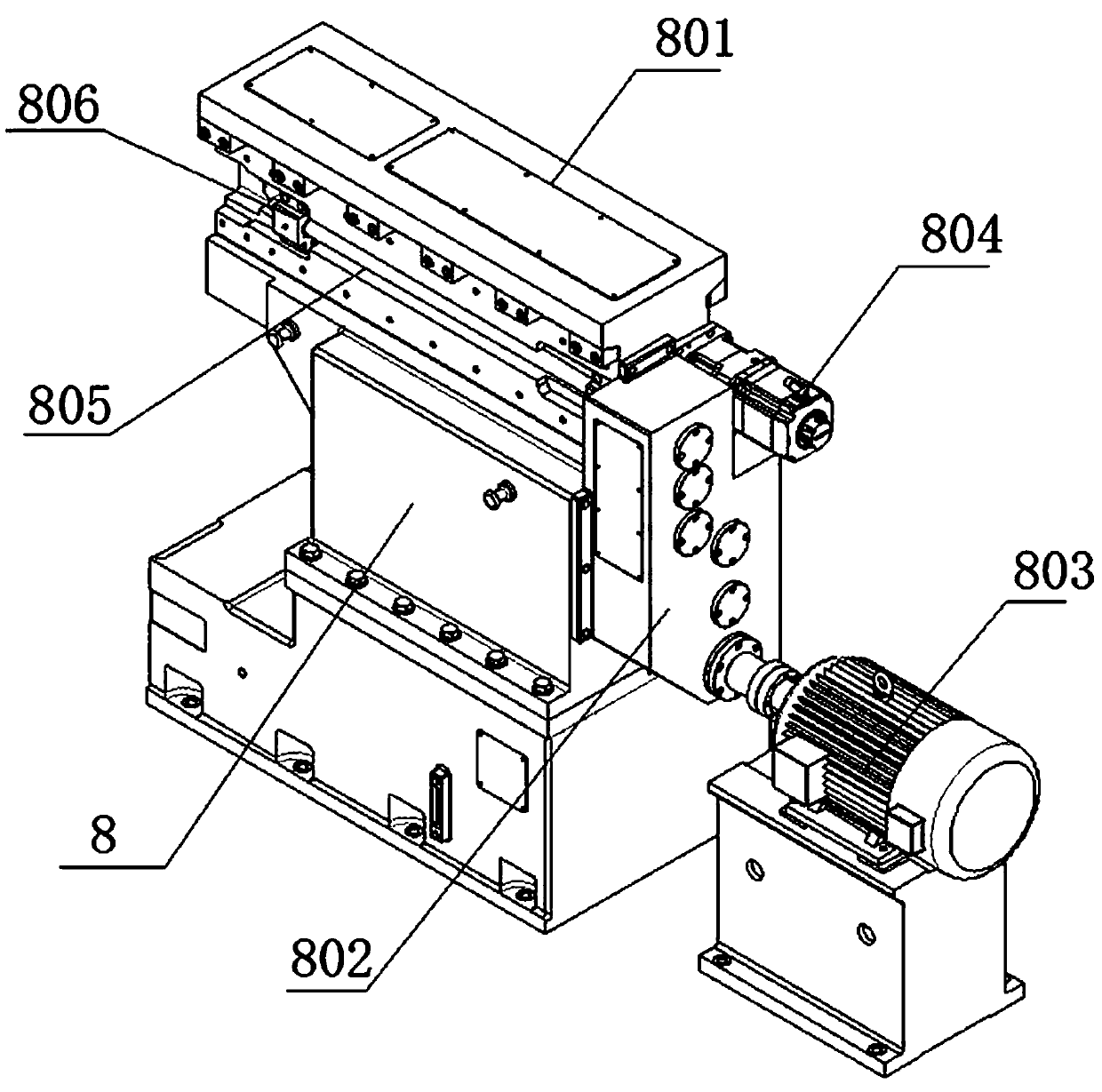

[0045] Such as Figure 1-20 As shown, a CNC deep hole keyway milling machine includes a machine bed 1, a machine electric cabinet 2, a machine control panel 3, a workbench 4, a support frame 5, a tailstock 6, a main transmission box 8, a cantilever boring frame 9, a milling machine Axle box 10, workbench driving motor 11, machine bed 1 is a horizontal bed, two parallel guide rails of machine bed 1 are installed with workbench 4, and the front end of workbench 4 is fixedly equipped with follow-up tailstock 6, The workbench 4 supports the deep-hole workpiece 7 through the supporting frame 5. The main transmission box 8 is provided behind the machine bed 1. The main transmission box 8 is provided with a cantilever boring frame 9 protruding forward. The two sides of the main transmission box 8 are respectively provided with There is a machine tool electrical cabinet 2 and a machine tool control panel 3, the machine tool electrical cabinet 2 is connected to each electrical componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com