Refractory silicone rubber, preparation method therefor and conducting wire

A silicone rubber and refractory technology, applied in the field of refractory materials, can solve the problems of complex processing technology, cumbersome production equipment, easy breakdown, etc., and achieve the effect of high residual amount, excellent mechanical and processing performance, and fast porcelain forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

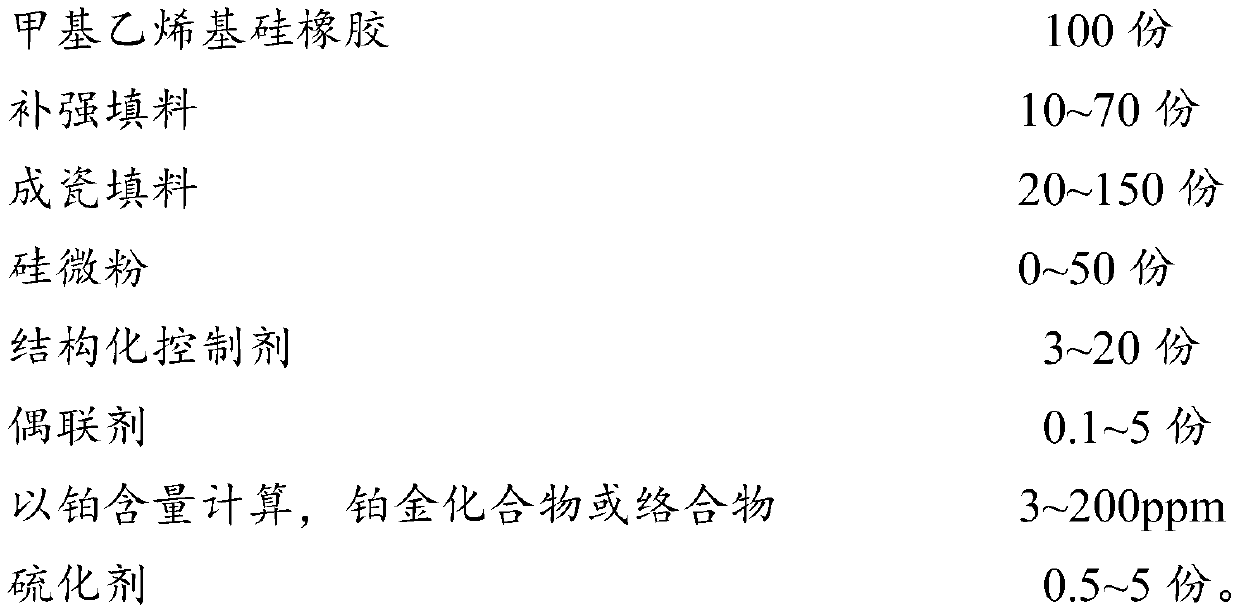

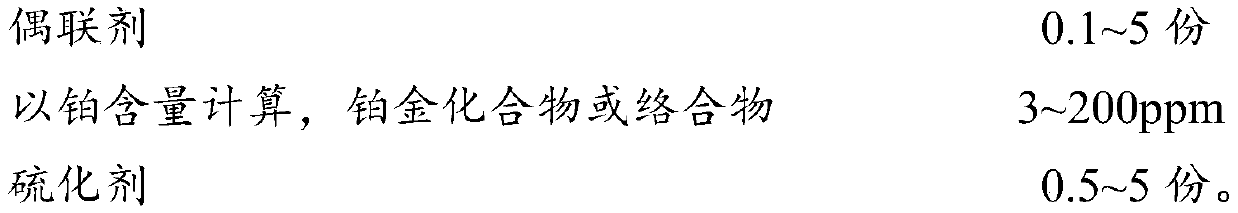

Method used

Image

Examples

Embodiment 1

[0035] Add 100 parts of methyl vinyl silicone rubber into a kneader and knead for 5 minutes, add 50 parts of precipitated silica and 8 parts of hydroxyl silicone oil in 5 times, and knead for 20 minutes each time to obtain base rubber A. Here, 50 parts of white carbon black and 8 parts of hydroxy silicone oil are divided into 5 additions mainly because of the long time of one addition, unstable performance, failure to produce qualified products, or high defective rate of products.

[0036] Add 50 parts of wollastonite, 30 parts of kaolin, and 2 parts of vinyltrimethoxysilane to the base rubber A in 4 times, and knead for 15 minutes each time to obtain the base rubber B; the temperature rises to 110 ° C, and vacuumizes for 1 hour. The temperature is -0.06 to -0.08MPa; lower the temperature to below 80°C, add 20 parts of silicon micropowder and 10ppm (based on platinum content) platinum vinyl complex, and continue kneading for 20min to obtain base C; cool the obtained base C Aft...

Embodiment 2

[0038] Add 100 parts of methyl vinyl silicone rubber into a kneader and knead for 5 minutes, add 50 parts of fumed silica and 70 parts of hydroxy silicone oil in 5 times, and knead for 20 minutes each time to obtain base rubber A; Add 60 parts of wollastonite, 20 parts of α-alumina, and 2 parts of vinyltrimethoxysilane in 4 times, and knead for 15 minutes each time to obtain the base rubber B; the temperature rises to 110 ° C, and the vacuum is started for 1 hour. -0.06MPa; lower the temperature to below 80°C, add 20 parts of silicon micropowder and 10ppm (based on platinum content) platinum vinyl complex, and continue kneading for 20 minutes to obtain base C; cool and filter the obtained base C, that is Refractory silicone rubber compounds are available.

Embodiment 3

[0040]Put 100 parts of methyl vinyl silicone rubber into the kneader and knead for 5 minutes, 20 parts of fumed silica, 20 parts of precipitated silica, and 8 parts of hydroxyl silicone oil, add in 5 times, knead for 20 minutes each time, and obtain the base Adhesive A; add 50 parts of wollastonite, 15 parts of α-alumina, 10 parts of talc, and 2.5 parts of vinyltriethoxysilane to the base A in 4 times, and knead for 15 minutes each time to obtain the base B; The temperature rises to 110°C, start vacuuming for 1 hour, and the vacuum degree is -0.065MPa; cool down to below 80°C, add 10 parts of silicon micropowder and 20ppm (based on platinum content) platinum vinyl complex, continue kneading for 20 minutes, and obtain the base Rubber C: After the obtained base rubber C is cooled and filtered, the refractory silicone rubber compound can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com