Underwater anti-explosion protection structure based on shock wave reflection energy dissipation

A protective structure and shock wave technology, applied in shipping equipment, climate change adaptation, etc., can solve problems such as unsuitable for long-term use, explosion-proof efficiency, poor chemical stability of film materials, and large explosion-proof walls, etc., to achieve significant energy dissipation and anti-explosion effects , The effect of energy dissipation is remarkable, and the effect of improving energy dissipation efficiency and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

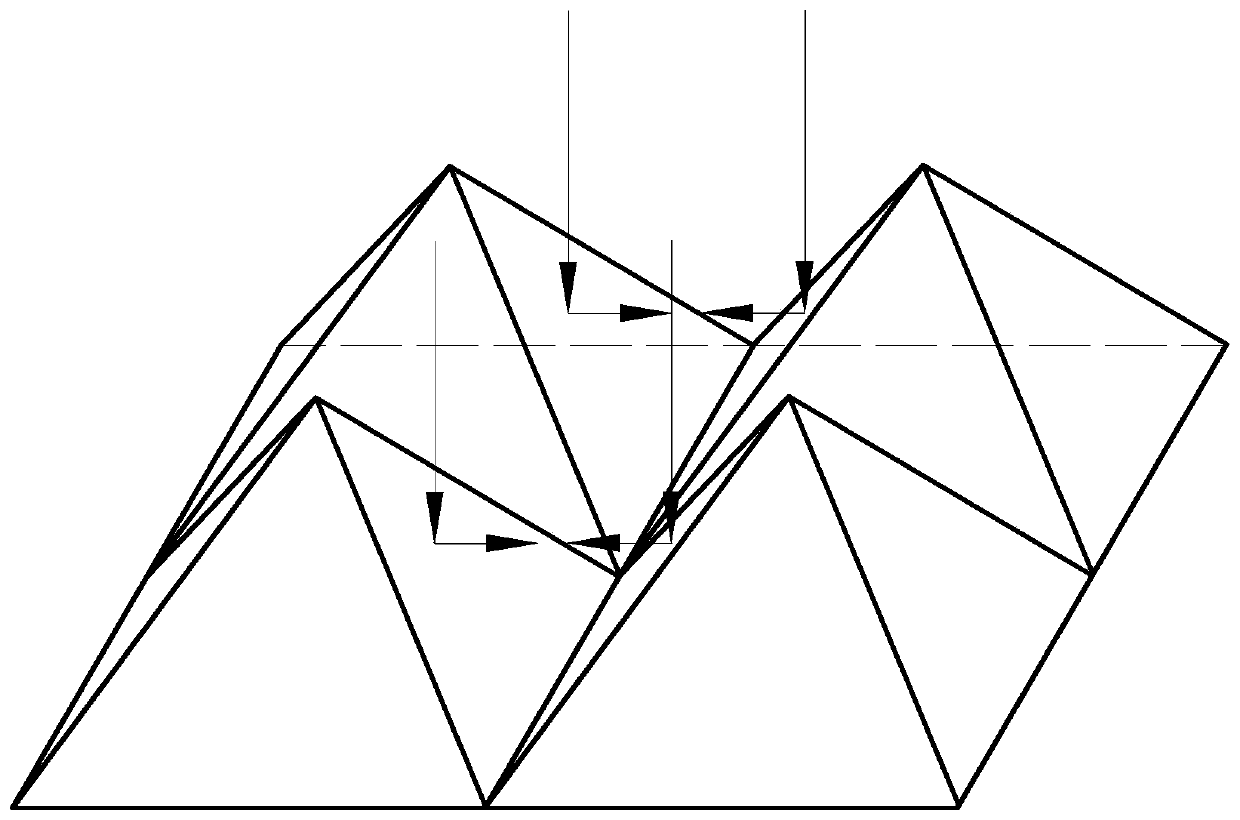

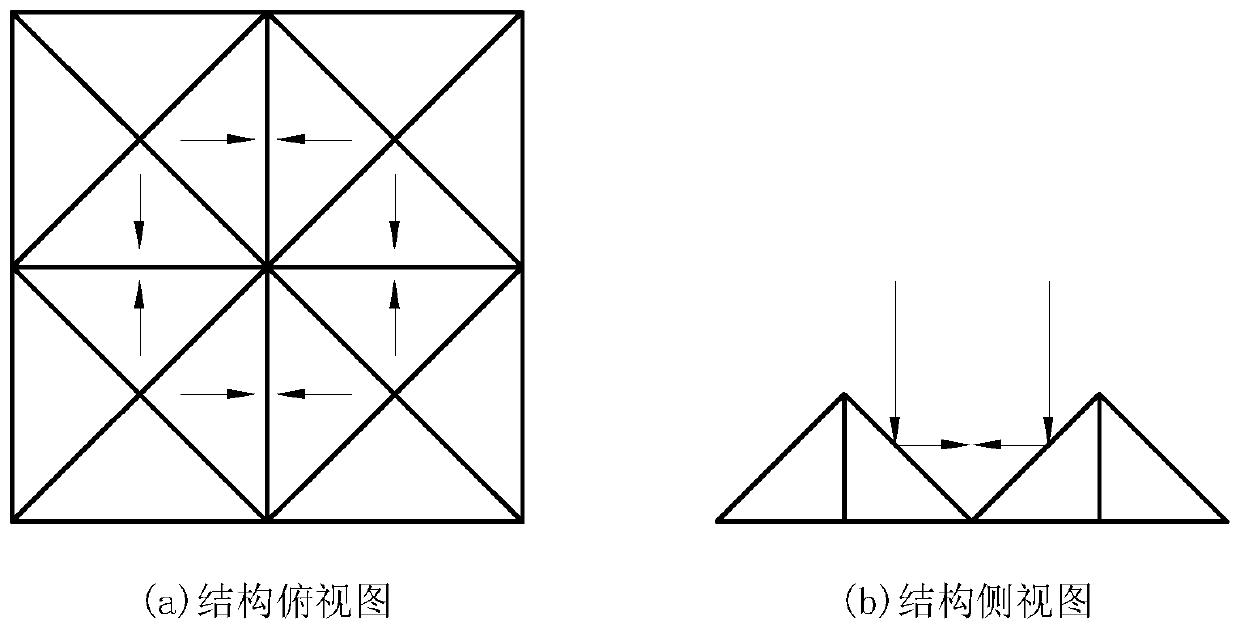

[0023] The underwater anti-explosion protection structure based on shock wave reflection energy dissipation according to the present invention will be described in detail below with reference to the accompanying drawings.

[0024]

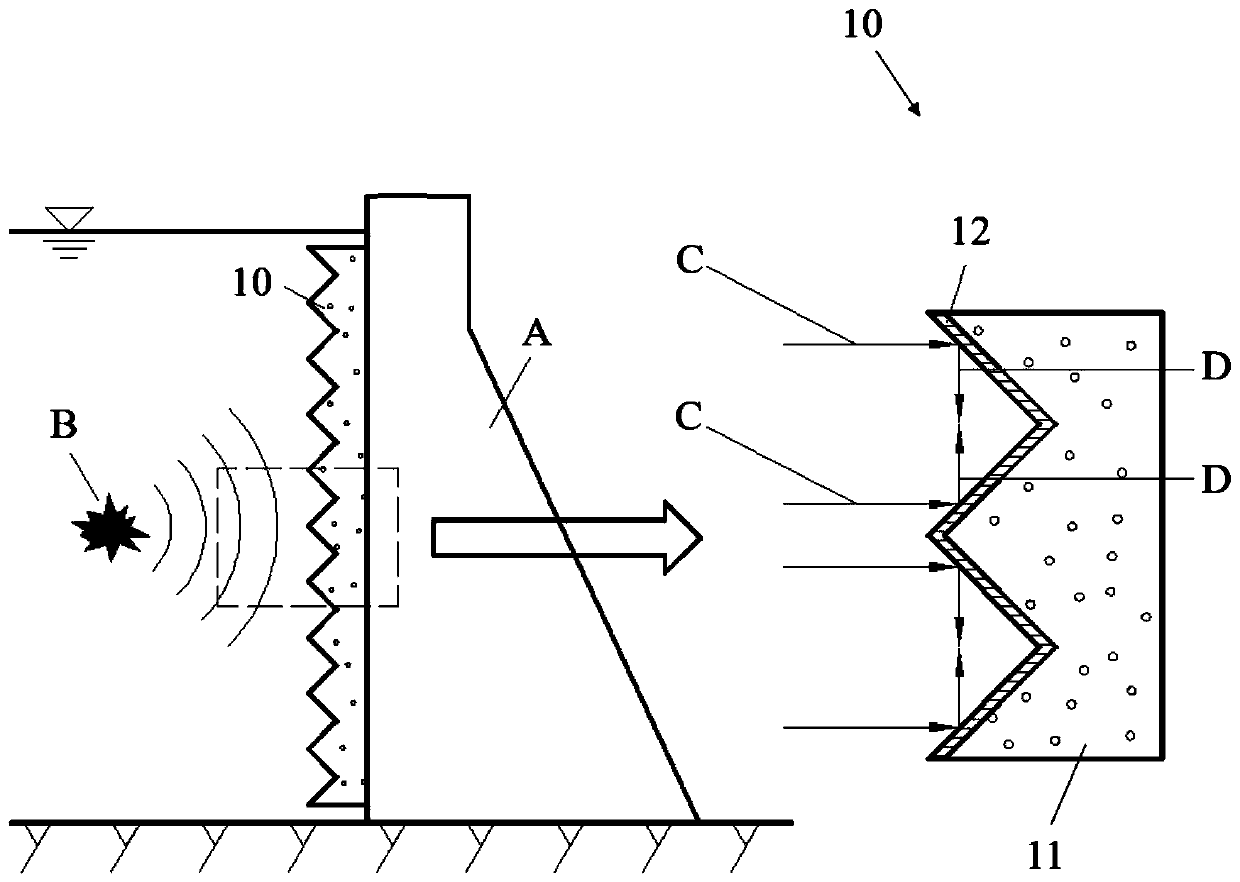

[0025] Such as figure 1 As shown, in this embodiment, a concrete gravity dam A with a height of 120 m under construction is taken as the object to be protected, and the structure of the underwater anti-explosion protection structure 10 and its application mode are described in detail.

[0026] While designing the concrete gravity dam A, the underwater anti-explosion protection structure 10 is designed on the water facing surface, and the thickness of the protection structure 10cm is reserved respectively. After making the template of the underwater anti-explosion protection structure 10, it is installed, and the concrete gravity dam A's main structure is constructed by in-situ pouring at the same time. During the on-site construction, starting from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com