A fiber-embedded superconducting tape and its preparation method

A technology of superconducting strips and superconducting bare strips, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of no explanation or report found, and the replaceability of superconducting strips and universal constraints, the data has not yet been collected, etc., to achieve the effect of mature technology and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

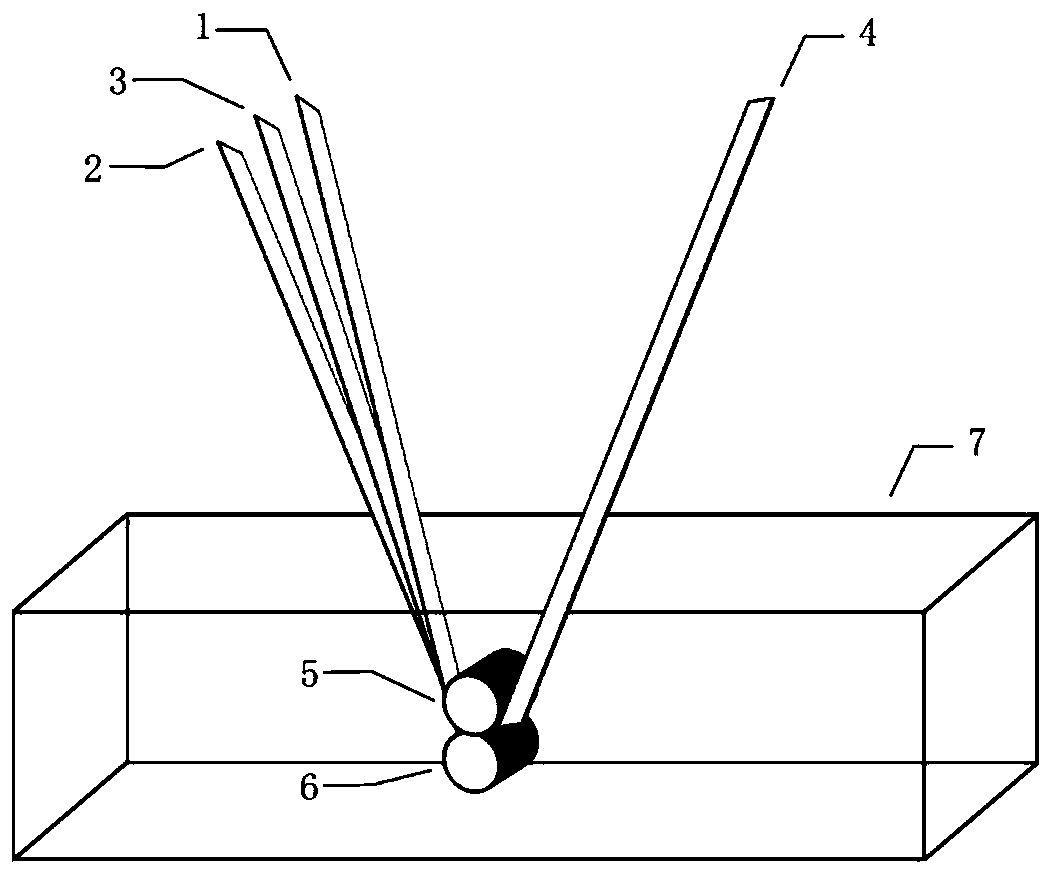

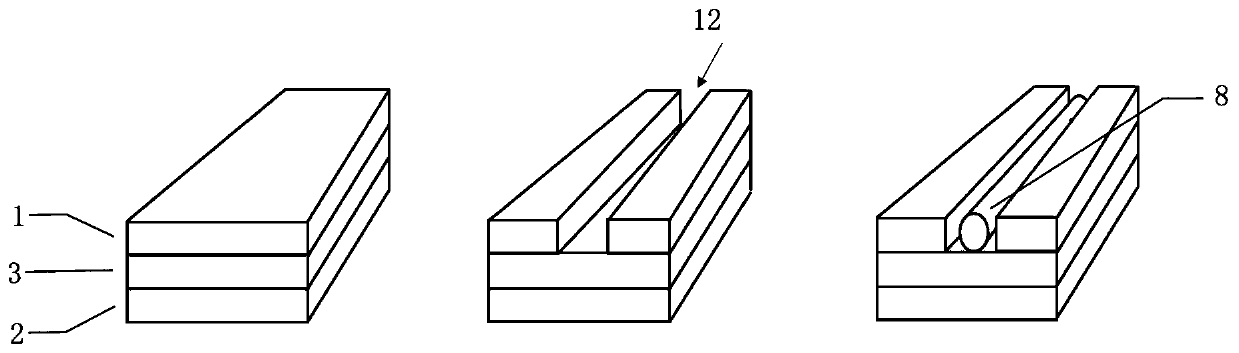

Embodiment 1

[0050] This embodiment provides a fiber-embedded superconducting tape, including an upper protective metal tape, a lower protective metal tape, a bare superconducting tape and a measuring optical fiber. The surface of the upper protective metal strip or the lower protective metal strip is engraved with one or more deep grooves along the length direction of the strip, and the measuring optical fiber is embedded in the deep groove. The depth of the deep groove is less than the thickness of the protective metal strip and greater than the diameter of the optical fiber, said bare superconducting tape is encapsulated between upper and lower protective metal tapes;

[0051] The surfaces of the upper protective metal strip and the lower protective metal strip are tinned;

[0052] The upper protective metal belt and the lower protective metal belt are made of red copper;

[0053] The measuring optical fiber is a commercial-grade single-mode optical fiber, the measuring optical fiber i...

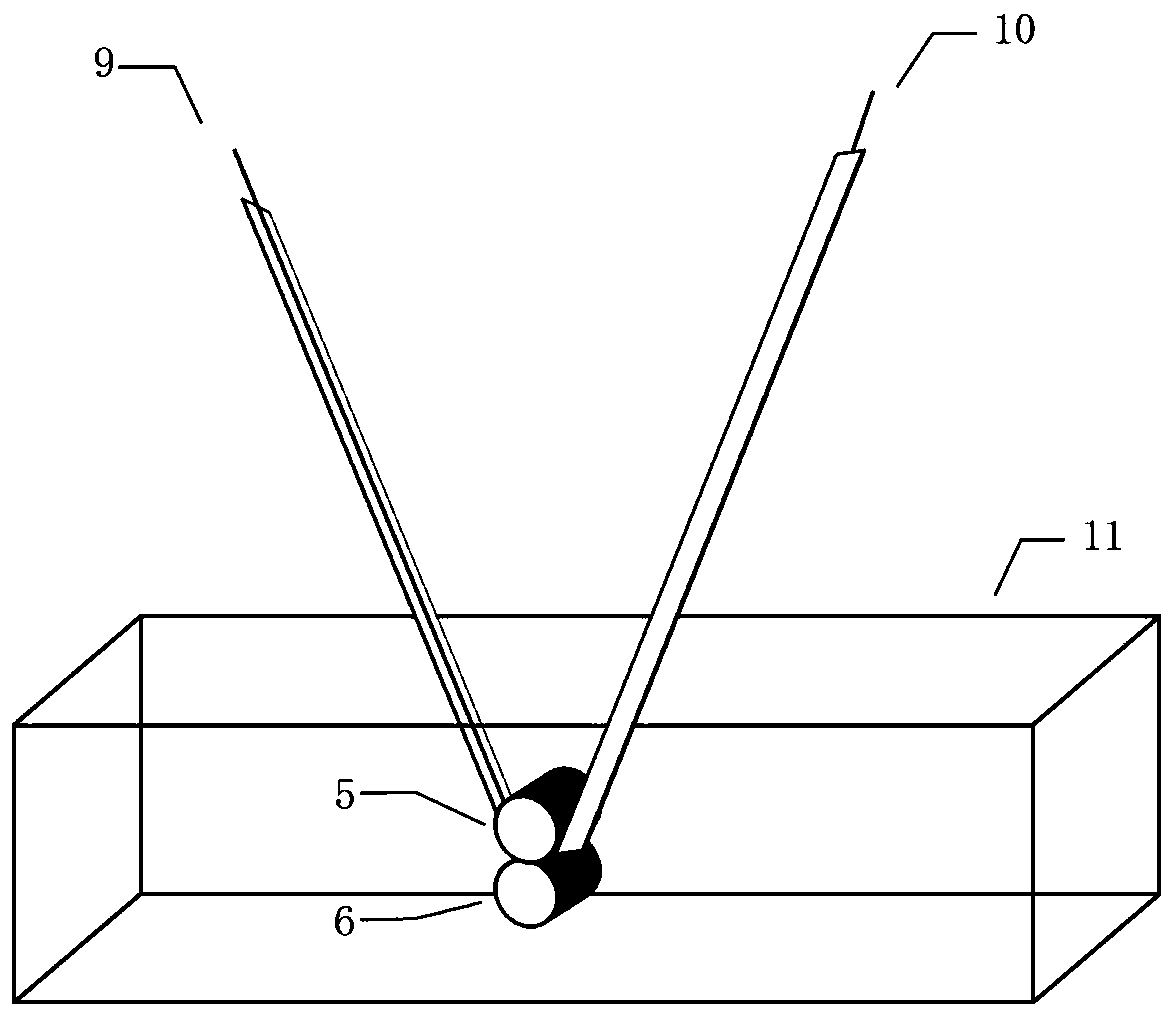

Embodiment 2

[0068] This embodiment provides a fiber-embedded superconducting tape, including an upper protective metal tape, a lower protective metal tape, a bare superconducting tape and a measuring optical fiber. The surface of the upper protective metal strip or the lower protective metal strip is engraved with one or more deep grooves along the length direction of the strip, and the measuring optical fiber is embedded in the deep groove. The depth of the deep groove is less than the thickness of the protective metal strip and greater than the diameter of the optical fiber, said bare superconducting tape is encapsulated between upper and lower protective metal tapes;

[0069] The surface of the upper protective metal strip and the lower protective metal strip has been tinned;

[0070] The upper protective metal belt and the lower protective metal belt are made of brass;

[0071] The measuring optical fiber can use a commercial-grade multimode optical fiber, the measuring optical fiber...

Embodiment 3

[0083] Content 1: In order to demonstrate the advantages of the present invention in the application of superconducting quench self-detection, this example uses the embedded optical fiber superconducting tape with quench self-detection function prepared in Example 1 to wind a single-cake superconducting coil , whose structure is as Figure 4 As shown, there is no insulating material between the turns of the coil; the optical fiber at the end of the superconducting strip is connected to the optical fiber temperature / stress demodulator through a jumper; the outgoing end of the superconducting coil is connected to a constant current power supply; Voltage leads; the voltage leads are connected to a digital multimeter. The constant current power supply system, voltage acquisition system, and temperature acquisition system are synchronously controlled by self-developed software.

[0084] The main structural parameters of the superconducting coil and the material description of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com