A bio-bead for biofouling control in membrane bioreactor

A technology of membrane bioreactors and reactors, applied in the field of composite materials, can solve problems such as biofouling control of anaerobic membrane bioreactors that have not yet been studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0160] It will be appreciated that the reaction product of adding the first mixture to the second mixture is a cross-linked polymer composite which is insoluble in the solvent used. Thus, the composite material of step (ii) of the production process can be easily separated from the liquid and then washed and dried - either for storage and / or in the above-mentioned wastewater treatment process, or for the optional coating step .

[0161] According to the requirements of the composite material suitable for use in anaerobic membrane bioreactors, or as suitable for the requirements of composite materials used in aerobic membrane bioreactors, the cross-linked polymer obtained in step (ii) of the above method The composite material can also be subjected to a coating step using a coating material. The method may include immersing the composite material formed in step (ii) of the above preparation method into a solution containing a suitable concentration of the desired coating mater...

Embodiment 1

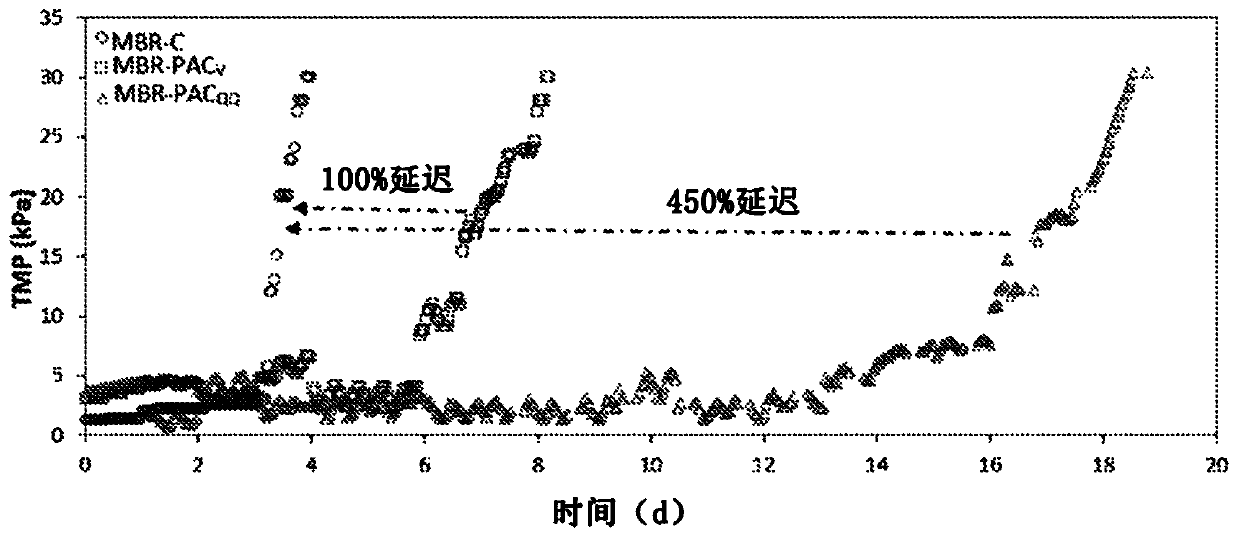

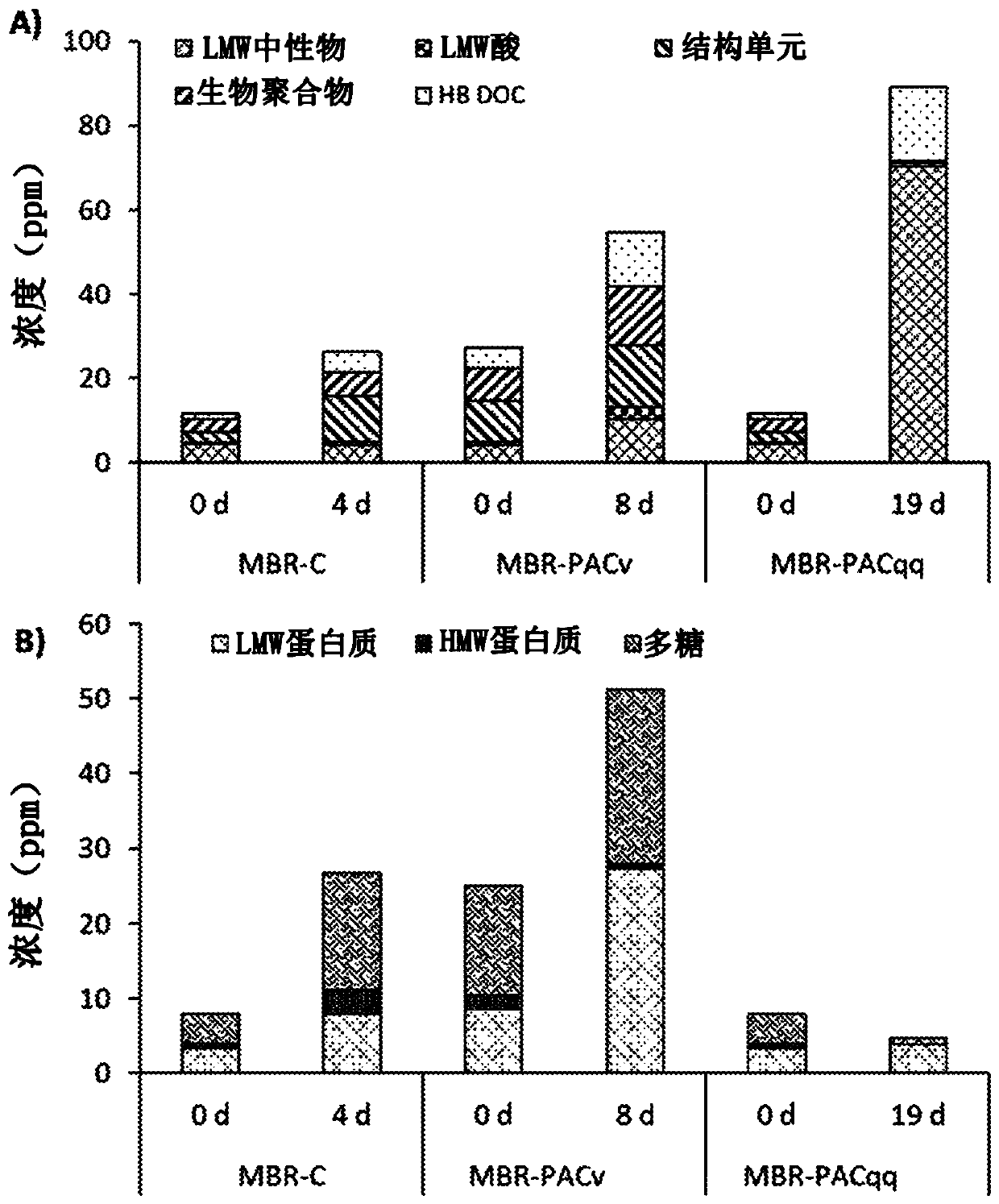

[0181] Example 1: Optimization of PAC bead composition and volume ratio of beads in the absence of QQ bacteria

[0182] Five independent sets of batch-scale experiments were performed with different bead compositions and bead dosages (volume ratio of beads to reactor), Table 1, to optimize the adsorption of pharmaceutically active compounds (PhACs).

[0183] method

[0184]PAC-alginate beads were prepared by mixing PAC (SAE2, Norit, the Netherlands) with sodium alginate solution (2% w / v) in different ratios (1% w / v or 2% w / v, see Table 1) Mix, and drop CaCl through the nozzle at a rate of 1 mL / min using a peristaltic pump 2 solution (4% w / v); in CaCl 2 After soaking in the solution for 3 h, half of the beads were immersed in a polysulfone solution (8% w / v in N-methyl-2-pyrrolidone) for 10 s, then transferred to Milli-Q water and stored at 4 °C until After use, transfer remaining beads directly to Milli-Q water. Beads without PAC were also prepared as a control.

[0185]...

Embodiment 2

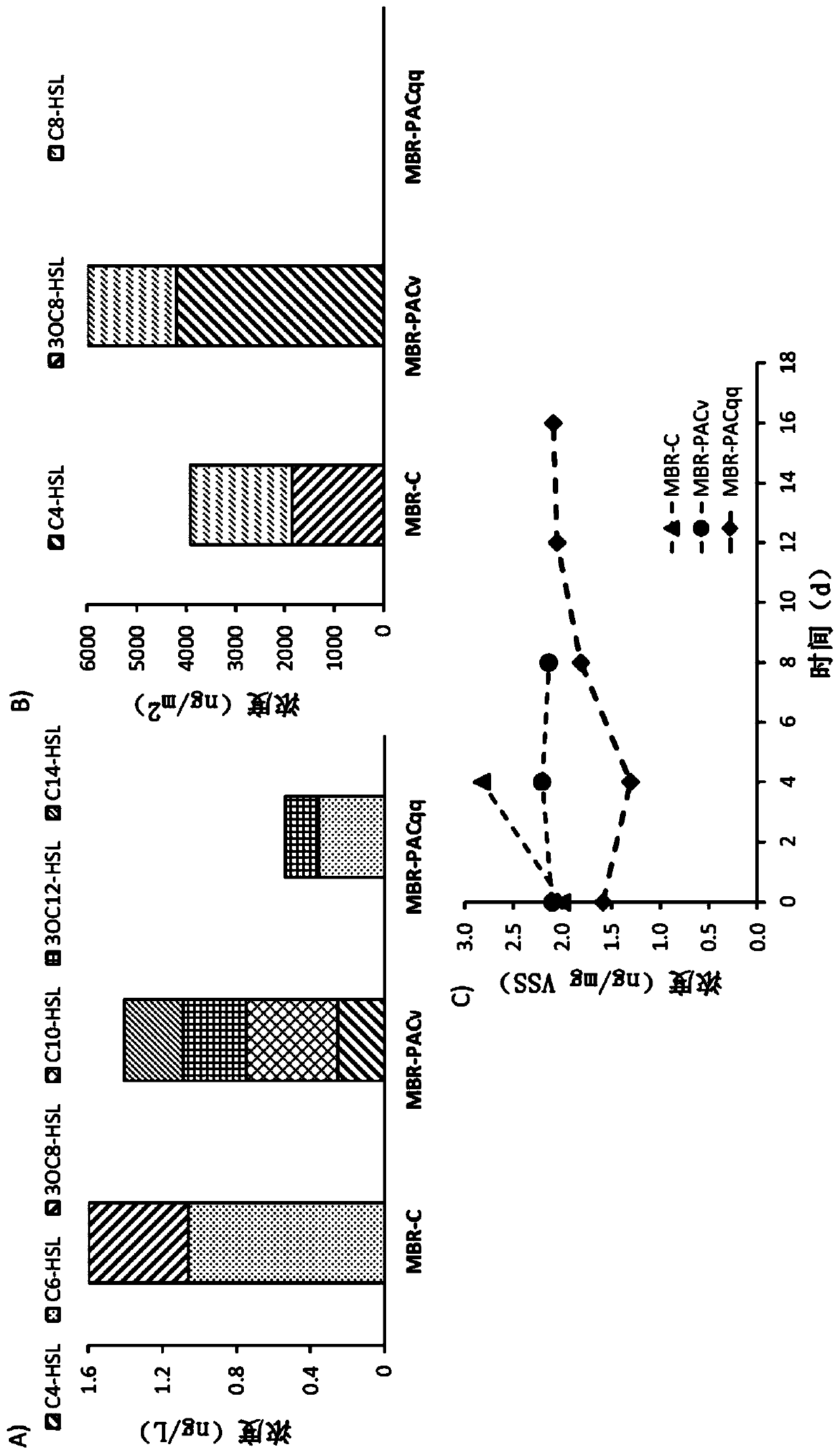

[0200] Embodiment 2: the preparation procedure of QQ-PAC beads

[0201] QQ-PAC beads for biofouling control and trace organic pollutant (TrOC) removal in MBR were prepared according to the following procedure.

[0202] 1. QQ bacteria were isolated from activated sludge and stored at -80°C. QQ bacteria were revived in Luria-Bertani (LB) broth prior to bead preparation. 50 μL of the revived culture (OD > 0.5) was then used to inoculate 5 mL of LB broth and the culture was incubated overnight at 30° C. before use.

[0203] 2. 5 mL of the overnight culture (OD 0.5) was harvested by centrifugation and resuspended in 5 mL of 1X phosphate buffered saline (PBS). 1x PBS with a final concentration of 10 mM PO 4 3 -, 137mM NaCl and 2.7mM KCl. The bacterial suspension was then added to 45 mL of a 2% (w / v; based on a 45 mL solution) sodium alginate solution containing 1% (w / v) PAC (SAE2, Norit, the Netherlands) and stirred to mix. Based on batch adsorption tests as detailed in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com