High-activity alpha-Fe2O3 nano-sheet as well as preparation method and application thereof

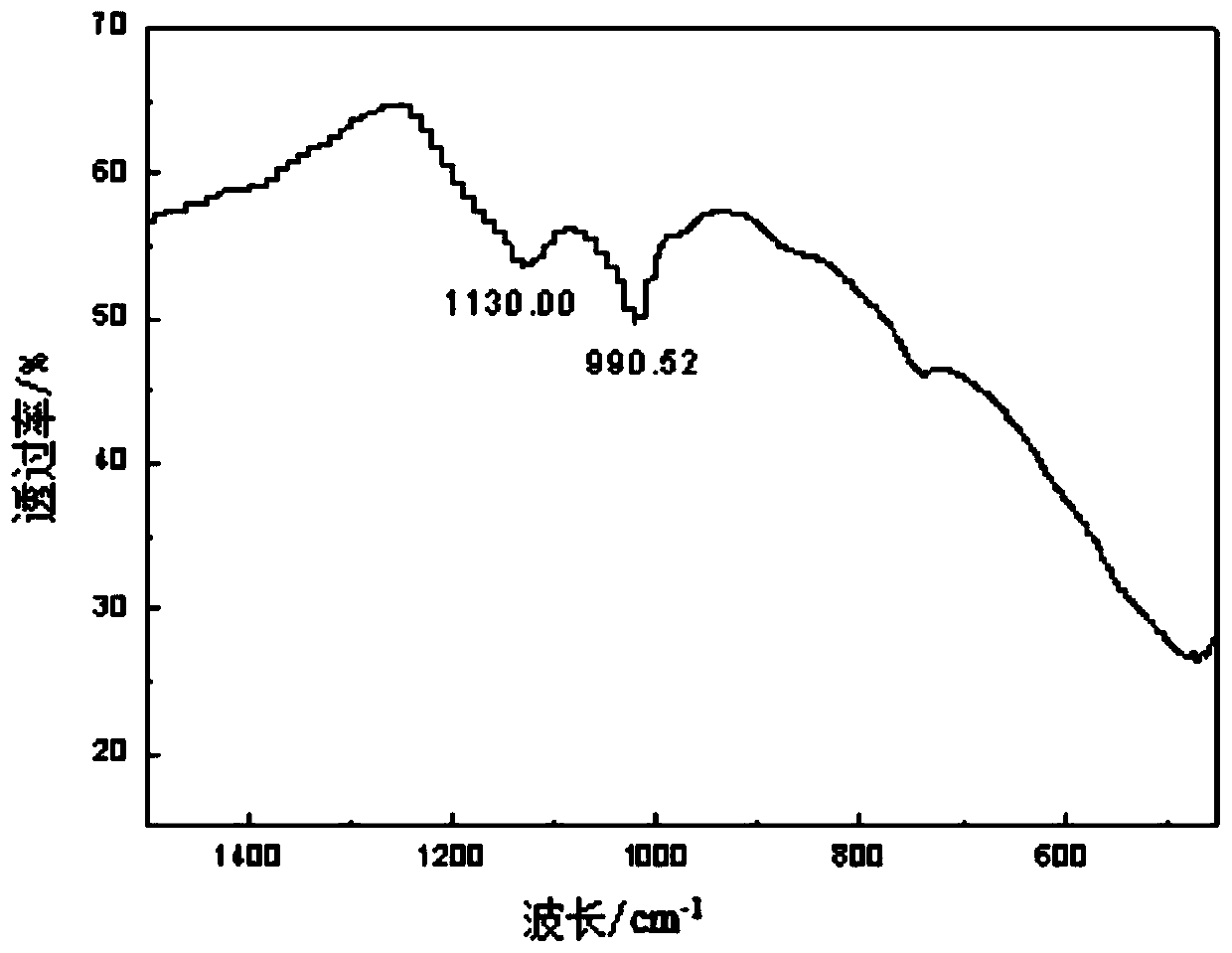

A nano-sheet and high-activity technology, which is applied in the field of high-activity α-Fe2O3 nano-sheet and its preparation, can solve the problems of uncontrollable shape, high preparation cost, and complicated preparation process, so as to improve the photocatalytic degradation activity and improve the catalytic performance. Activity, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A highly active α-Fe 2 o 3 A method for preparing nanosheets, comprising the steps of:

[0048] Step 1. Preparation of FeSO 4 Solution: Weigh about 28g low-carbon iron sheet, dissolve in 245g 20% H 2 SO 4 Solution, filter to remove impurities, titrate with potassium dichromate, calculate FeSO 4 concentration, and then the prepared FeSO 4 Solution diluted to 0.5mol / L;

[0049] Step 2. Preparation of δ-FeOOH precursor: take the FeSO prepared above 4 Put 100ml of the solution in a 250ml beaker, add 50ml of 0.01mol / L EDTA solution, adjust the pH to 8.7 with 6mol / L NaOH solution, and use 0.27m 3 .h -1 Air was introduced at a rate of 1.5 h at 20°C, filtered, washed with distilled water, and dried at 70°C for 5 h to obtain the δ-FeOOH precursor;

[0050] Step 2: Take 2.5 g of the δ-FeOOH precursor prepared above, add Na 2 SiO 3 9H 2 O 63.9mg, citric acid 50mg, add 50ml of distilled water, disperse evenly, adjust the pH to 7, transfer to a polytetrafluoroethylene-...

Embodiment 2

[0052] A highly active α-Fe 2 o 3 A method for preparing nanosheets, comprising the steps of:

[0053] Step 1. Preparation of FeSO 4 Solution: Weigh about 28g low-carbon iron sheet, dissolve in 245g 20% H 2 SO 4 Solution, filter to remove impurities, titrate with potassium dichromate, calculate FeSO 4 concentration, and then the prepared FeSO 4 Solution diluted to 0.1mol / L;

[0054] Step 2. Preparation of δ-FeOOH precursor: take the FeSO prepared above 4 Put 100ml of the solution in a 250ml beaker, add 10ml of 0.04mol / L EDTA solution, adjust the pH to 8.9 with 6mol / L NaOH solution, and use 0.30m 3 .h -1 Air was passed in at a rate of 25°C for 1 hour, filtered and washed with distilled water, and dried at 70°C for 5 hours to obtain the δ-FeOOH precursor;

[0055] Step 2: Take 1 g of the δ-FeOOH precursor prepared above, add Na 2 SiO 3 9H 2 O 95.8mg, citric acid 70mg, add 50ml of distilled water, disperse evenly, adjust the pH to 5, transfer to a polytetrafluoroeth...

Embodiment 3

[0057] A highly active α-Fe 2 o 3 A method for preparing nanosheets, comprising the steps of:

[0058] Step 1. Weigh about 28g of low-carbon iron sheet and dissolve it in 245g of 20% H 2 SO 4 Solution, filter to remove impurities, titrate with potassium dichromate, calculate FeSO 4 concentration, and then the prepared FeSO 4 Solution diluted to 0.3mol / L;

[0059] Step 2. Preparation of δ-FeOOH precursor: take the FeSO prepared above 4 Solution 100ml, put in a 250ml beaker, add 30ml 0.02mol / LEDTA solution, adjust pH to 8.8 with 6mol / L NaOH solution, take 0.28m 3 .h -1 Air was introduced at the rate of 23°C for 1.5h, filtered and washed with distilled water, and dried at 70°C for 5h to obtain the δ-FeOOH precursor;

[0060] Step 2: Take 4 g of the δ-FeOOH precursor prepared above, add Na 2 SiO 3 9H 2 O 83mg, citric acid 30mg, add 50ml of distilled water, disperse evenly, adjust the pH to 3, transfer to a polytetrafluoroethylene-lined stainless steel reactor, react at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com