A beneficiation method for dry separation and recovery of iron-bearing useful rocks

A beneficiation method and dry beneficiation technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of waste of iron ore resources, high recovery cost, etc., achieve short connection time, simple and compact structure, prevent electricity bills and The effect of equipment depreciation losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

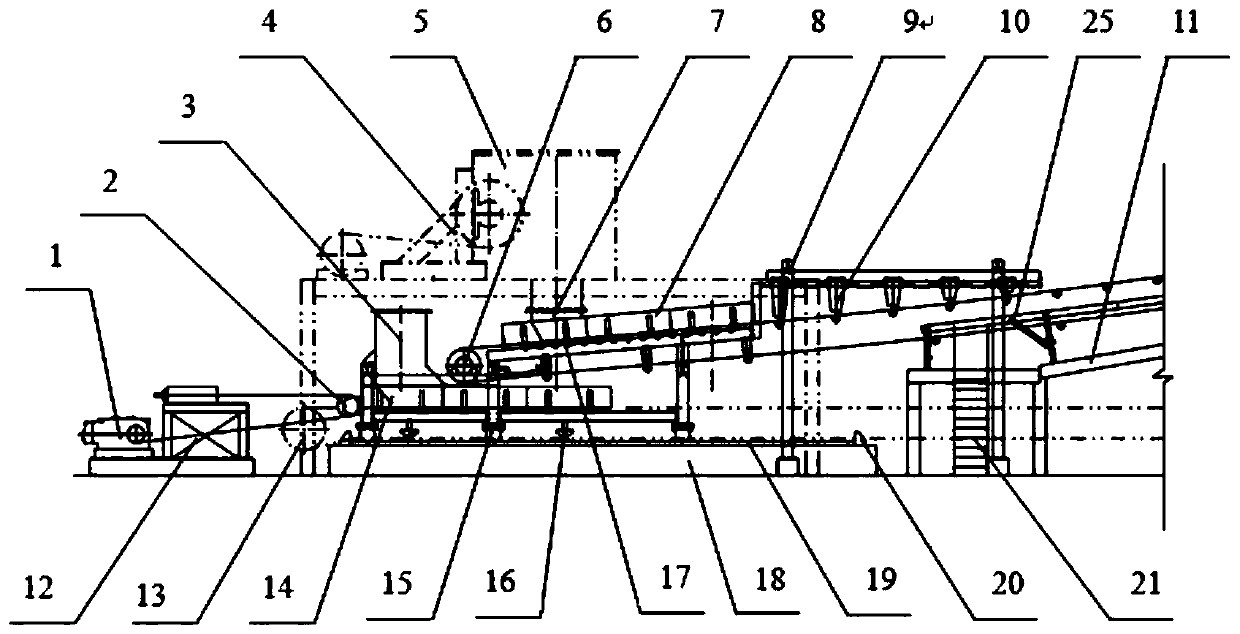

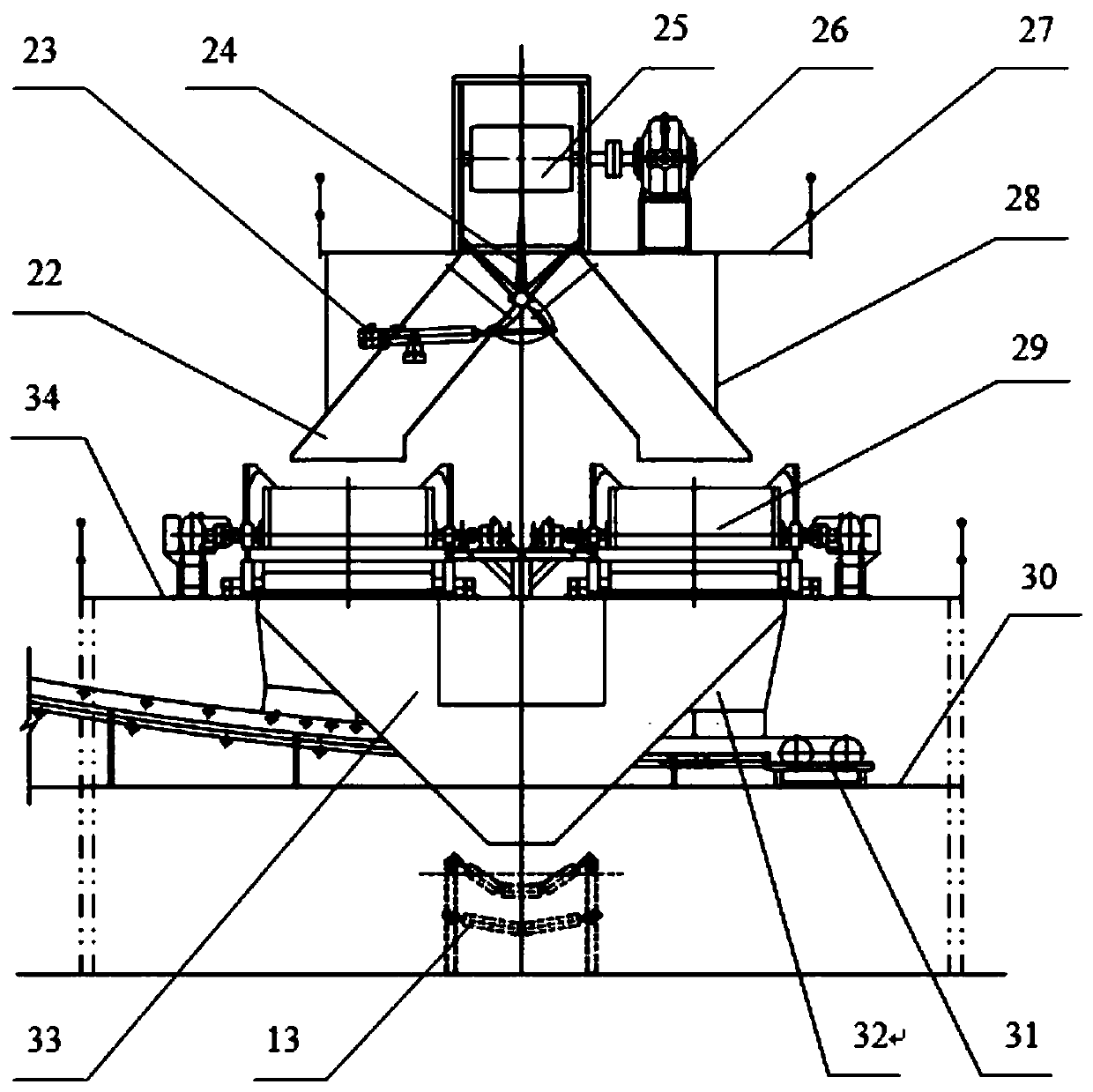

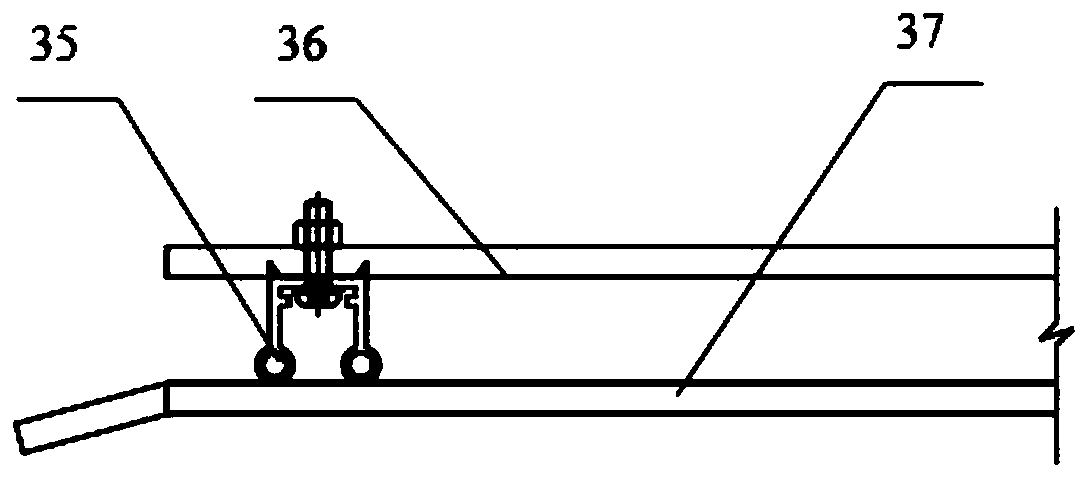

[0030]In order to better describe the present invention, a beneficiation method for dry separation and recovery of useful iron-containing rocks of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] Depend on figure 1 The material receiving part structural diagram of the dry separation recovery system that the present invention adopts shown and combine figure 2 It can be seen that the dry separation recovery system adopted in a kind of mineral processing method for iron-containing useful rock dry separation recovery of the present invention is composed of the iron-containing useful rock dry separation recovery system material receiving part and the iron-containing useful rock dry separation recovery dry separation part combination into:

[0032] The receiving part of the iron-containing useful rock dry separation recovery system contains the original stope main tape 4 and the original dump site main tape 13;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com