Modified anti-cracking concrete expanding agent and preparation method thereof

An expansion agent and concrete technology, applied in the field of concrete expansion agent, can solve problems such as insignificant expansion effect, affecting product quality, uneven mixing, etc., achieve good mixing effect, improve mixing effect, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A modified anti-cracking concrete expansion agent, prepared from the following raw materials in parts by weight, 20 parts of modified calcium oxide, 1 part of calcium sulfoaluminate, 5 parts of fly ash, 20 parts of fluorogypsum, 15 parts of aluminum oxide, 5 parts of Parts of dihydrate gypsum, 15 parts of magnesite, 4 parts of calcium carbonate, 12 parts of modified expandable graphite and 5 parts of composite modifier;

[0040] Wherein, the expansion agent is prepared through the following steps:

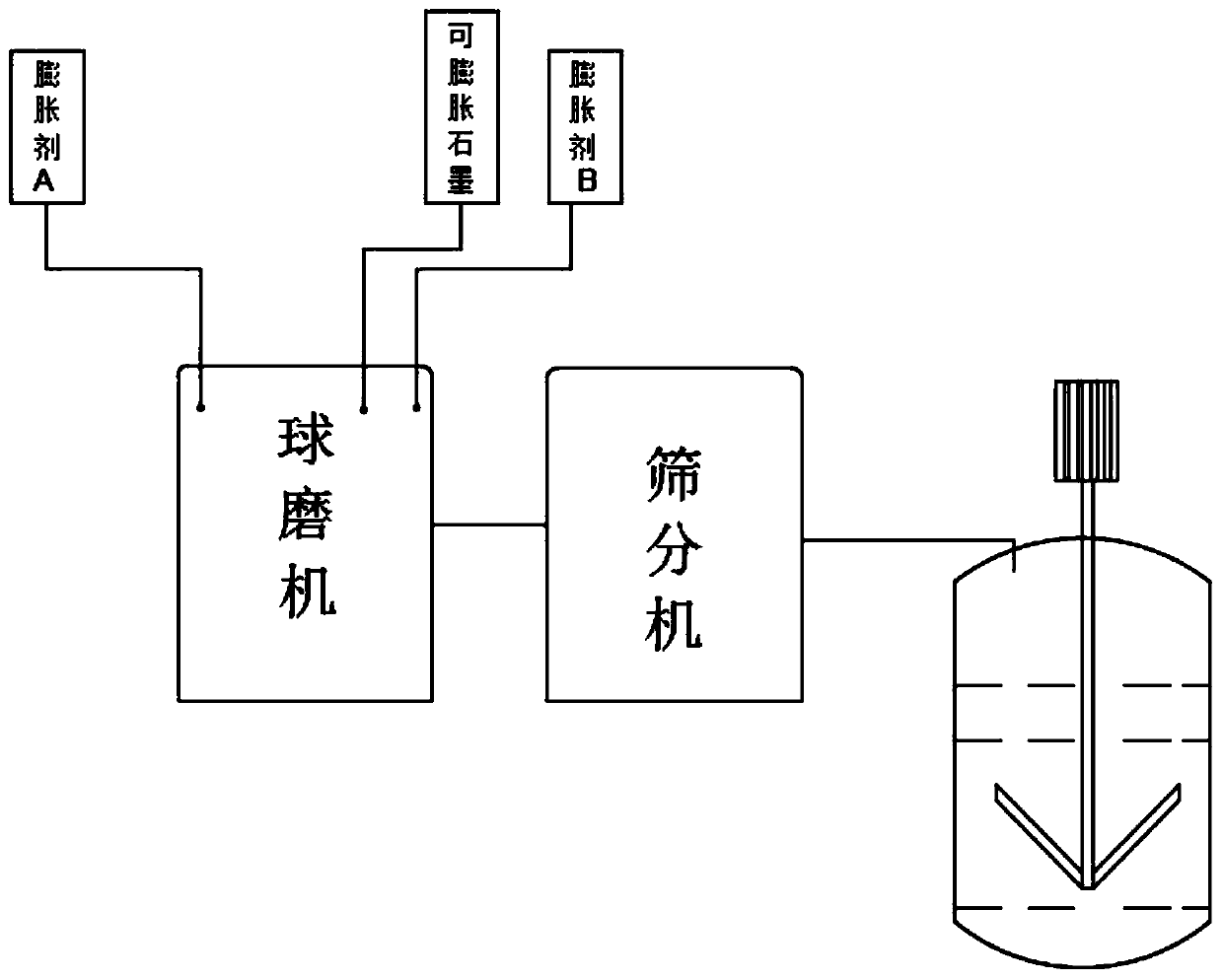

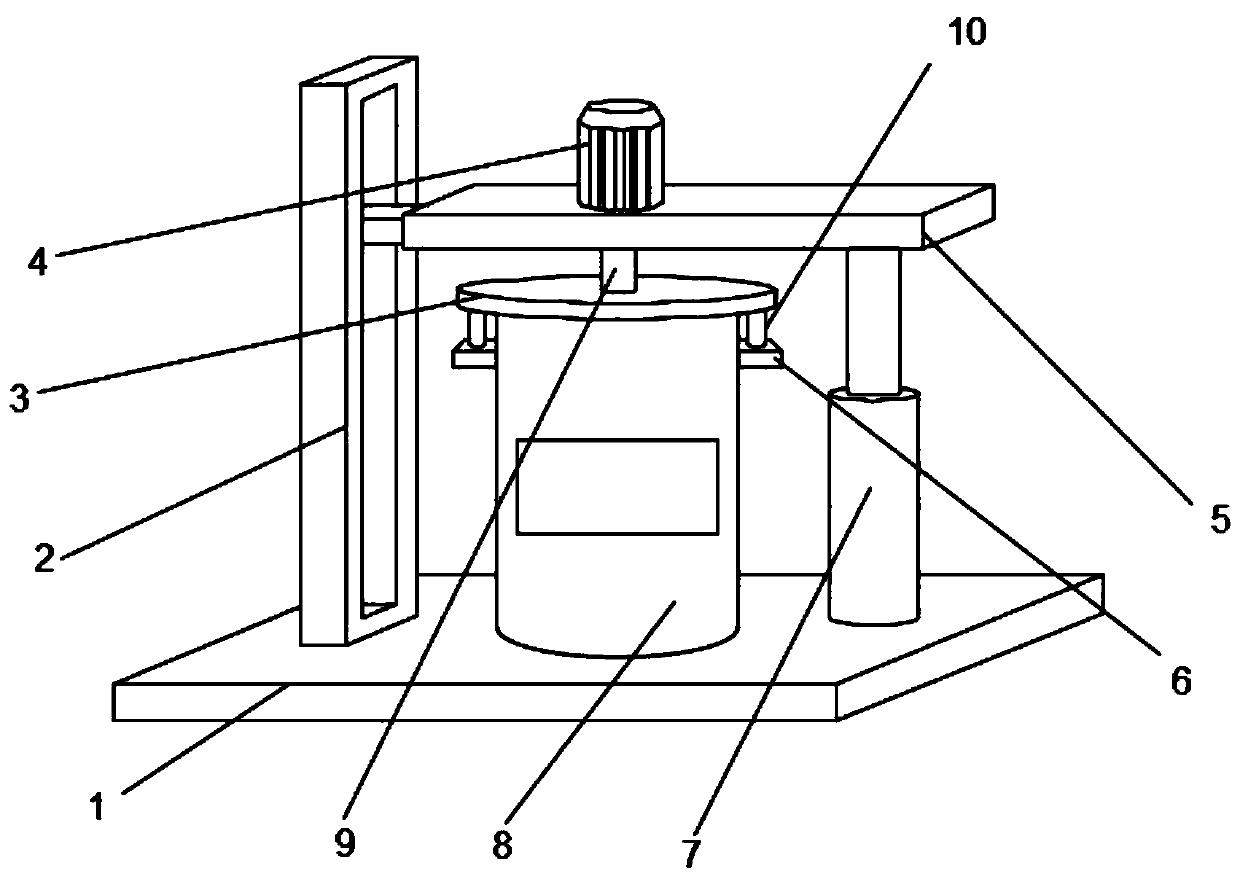

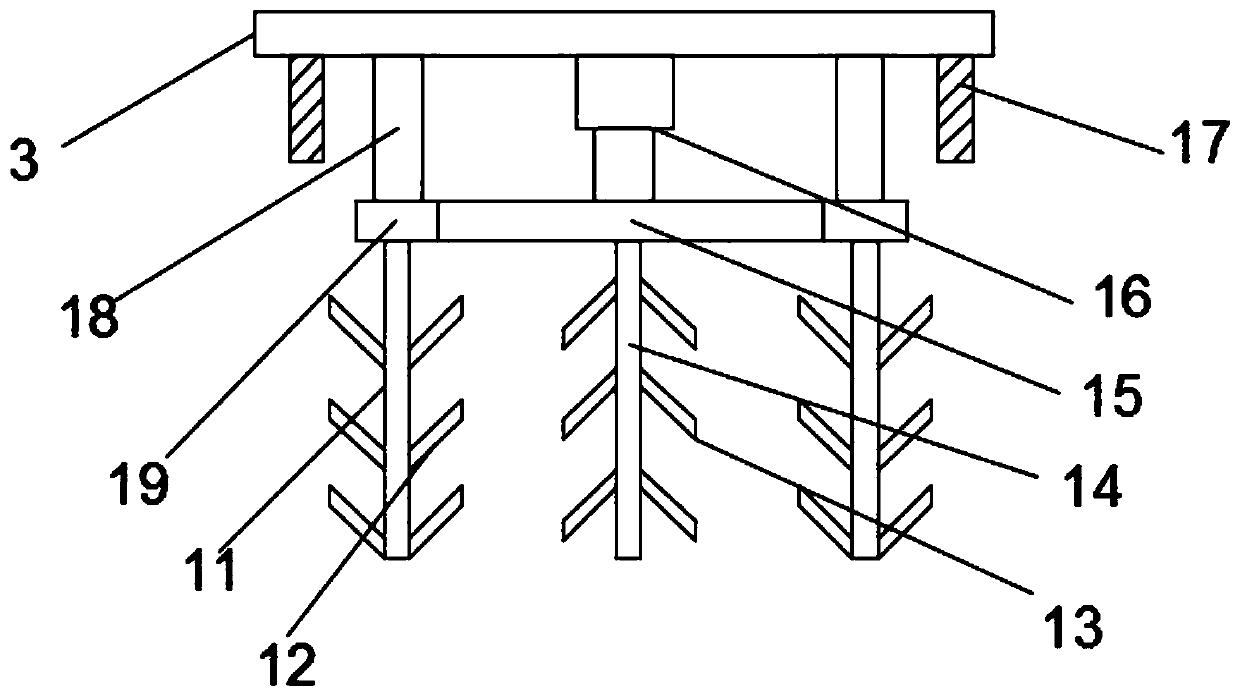

[0041] Step 1. First, add the weighed calcium sulfoaluminate to the grinder, and at the same time add a composite modifier to the grinder, mix and grind for 10 minutes, and dry at 60°C. Finally, add modified calcium oxide, stir and mix After uniformity, ball milling is carried out until the particle size is 50um, and the expansion agent A is obtained;

[0042] Step 2. Dry the weighed fly ash, fluorogypsum, alumina, dihydrate gypsum, magnesite and calcium carbonate respectiv...

Embodiment 2

[0052] A modified anti-cracking concrete expansion agent, prepared from the following raw materials in parts by weight, 10 parts of modified calcium oxide, 1 part of calcium sulfoaluminate, 3 parts of fly ash, 10 parts of fluorogypsum, 5 parts of aluminum oxide, 1 part of Parts of dihydrate gypsum, 5 parts of magnesite, 2 parts of calcium carbonate, 8 parts of modified expandable graphite and 1 part of composite modifier;

[0053] The preparation method of concrete expansive agent is identical with embodiment 1.

Embodiment 3

[0055] A modified anti-cracking concrete expansion agent, prepared from the following raw materials in parts by weight, 20 parts of modified calcium oxide, 5 parts of calcium sulfoaluminate, 3 parts of fly ash, 10 parts of fluorogypsum, 15 parts of aluminum oxide, 1 1 part of dihydrate gypsum, 5-15 parts of magnesite, 4 parts of calcium carbonate, 8 parts of modified expandable graphite and 5 parts of composite modifier;

[0056] The preparation method of concrete expansive agent is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com