A kind of amorphous nano-titanium dioxide sandwich pavement brick and preparation method thereof

A nano-titanium dioxide, sandwich technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology and other directions, can solve the problems of environmental pollution, large product particle size, calcination of agglomerated products, etc., to achieve large specific surface area, good environmental protection performance, The effect of good water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

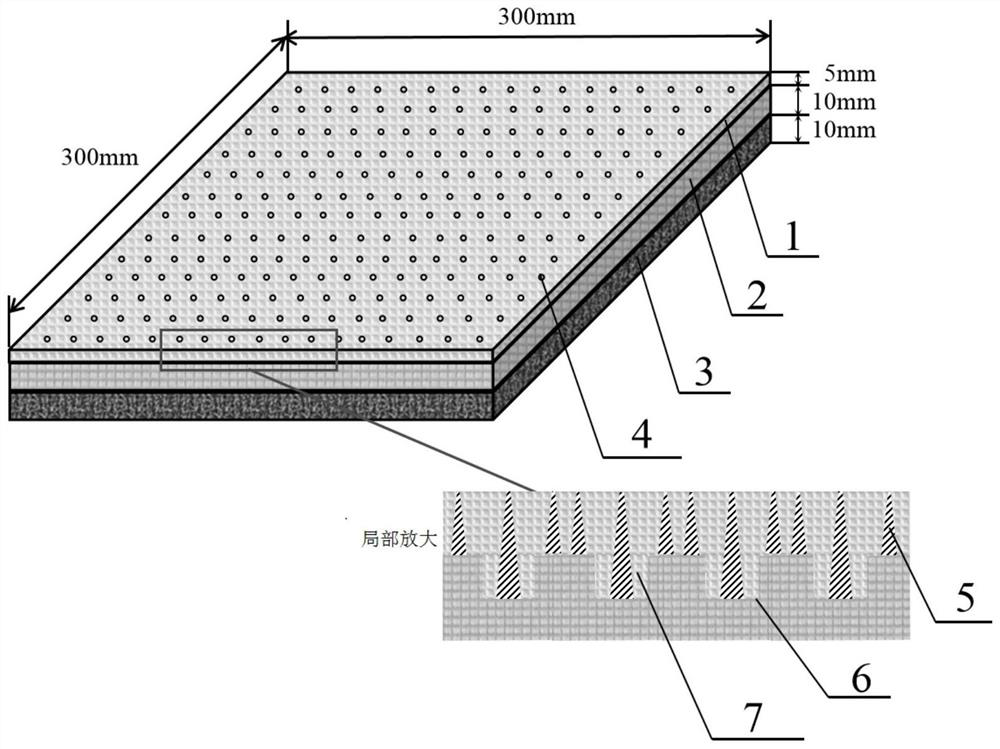

[0052] (1) An amorphous nano-titanium dioxide sandwich pavement brick, the sandwich pavement brick comprises a bottom layer, a middle layer and a surface layer, the bottom layer is prepared from the following raw materials in parts by weight, 30 parts of slag ash, 35 parts of cement, and 30 parts of stone powder parts, 5 parts of epoxy resin and 0.05 parts of epoxy resin curing agent; the middle layer is prepared from the following raw materials in parts by weight, 15 parts of slag ash, 35 parts of waste plastic powder, 25 parts of cement, 15 parts of stone powder, epoxy 10 parts of resin and 0.1 part of epoxy resin curing agent; the surface layer is prepared from the raw materials of the following parts by weight, amorphous nano-TiO 2 20 parts, 15 parts of slag ash, 5 parts of waste plastic powder, 30 parts of cement, 15 parts of stone powder, 15 parts of epoxy resin and 0.15 parts of epoxy resin curing agent.

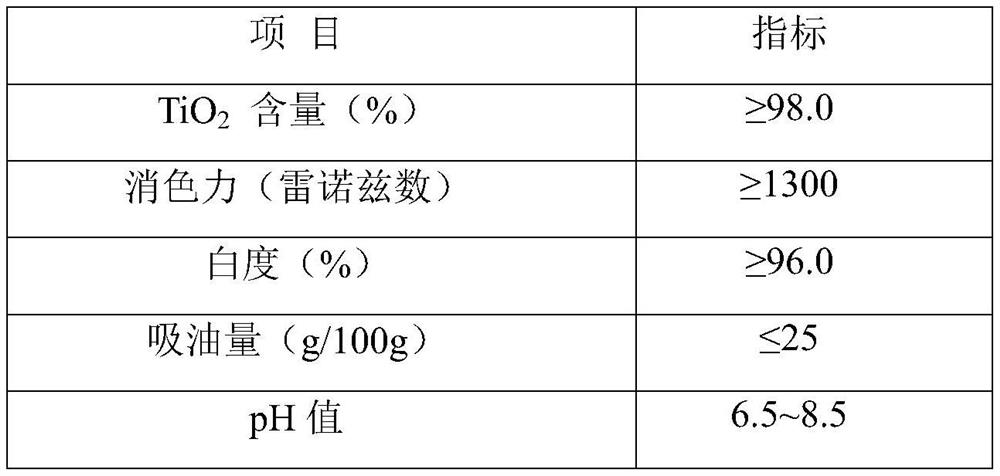

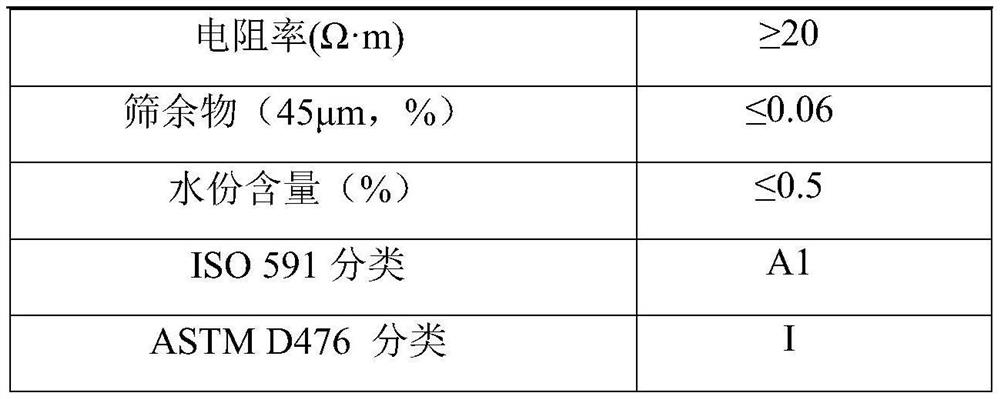

[0053] (2) The amorphous nano-TiO 2 Prepared by the following ...

Embodiment 2

[0078] (1) An amorphous nano-titanium dioxide sandwich pavement brick, the sandwich pavement brick includes a bottom layer, a middle layer and a surface layer, the bottom layer is prepared from the following raw materials in parts by weight, 31 parts of slag ash, 36 parts of cement, and 31 parts of stone powder parts, 6 parts of epoxy resin and 0.06 parts of epoxy resin curing agent; the middle layer is prepared from the following raw materials in parts by weight, 16 parts of slag ash, 36 parts of waste plastic powder, 26 parts of cement, 16 parts of stone powder, epoxy 11 parts of resin and 0.11 parts of epoxy resin curing agent; the surface layer is prepared from the raw materials of the following parts by weight, amorphous nano-TiO 2 21 parts, 16 parts of slag ash, 6 parts of waste plastic powder, 31 parts of cement, 16 parts of stone powder, 16 parts of epoxy resin and 0.16 parts of epoxy resin curing agent.

[0079] (2) The amorphous nano-TiO 2 Prepared by the following...

Embodiment 3

[0104] (1) An amorphous nano-titanium dioxide sandwich pavement brick, the sandwich pavement brick includes a bottom layer, a middle layer and a surface layer, the bottom layer is prepared from the following raw materials in parts by weight, 32 parts of slag ash, 37 parts of cement, and 32 parts of stone powder parts, 7 parts of epoxy resin and 0.07 parts of epoxy resin curing agent; the middle layer is prepared from the following raw materials in parts by weight, 17 parts of slag ash, 37 parts of waste plastic powder, 27 parts of cement, 17 parts of stone powder, epoxy 12 parts of resin and 0.12 parts of epoxy resin curing agent; the surface layer is prepared from the raw materials of the following parts by weight, amorphous nano TiO 2 22 parts, 17 parts of slag ash, 7 parts of waste plastic powder, 32 parts of cement, 17 parts of stone powder, 17 parts of epoxy resin and 0.17 parts of epoxy resin curing agent.

[0105] (2) The amorphous nano-TiO 2 Prepared by the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com