A preparation and regulation method of superhydrophobic/superhydrophilic reversible regulation of metal surface

A metal surface, super-hydrophobic technology, applied in the field of metal surface treatment, can solve the problems of high cost, complicated preparation process, difficult implementation, etc., and achieve the effect of low production cost, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

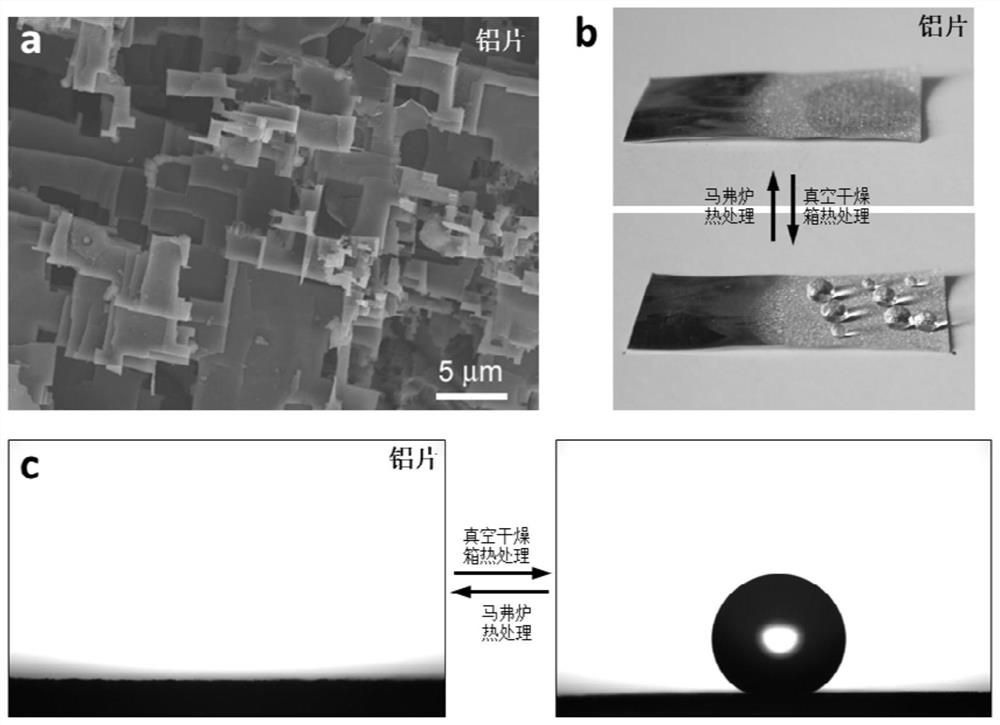

[0032] Cut an aluminum sheet with a size of 5 × 2.5 × 0.03 cm, first polish it with 240-grit sandpaper, and then polish it with 600-grit sandpaper, clean the metal surface with ethanol, acetone, and distilled water in sequence, and dry it naturally; use a concentration of 3mol / L The hydrochloric acid solution corrodes the cleaned aluminum sheet at 25°C for 15 minutes, rinses it with distilled water, and places it in the air to dry naturally; put the corroded and dried aluminum sheet at a temperature of 150°C Heat in a vacuum drying oven under normal pressure for 72 hours, and cool naturally to room temperature to obtain a superhydrophobic aluminum sheet; put the prepared superhydrophobic aluminum sheet in a muffle furnace at 450°C for 24 hours, and naturally cool to room temperature, the superhydrophobic aluminum sheet The sheet becomes a superhydrophilic aluminum sheet; repeating the above-mentioned 150°C vacuum drying oven heat treatment and 450°C muffle furnace heat treatmen...

Embodiment 2

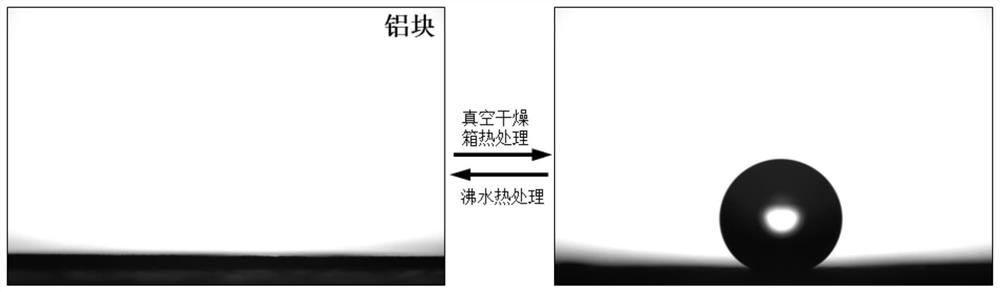

[0034] (1) Cut out an aluminum block with a size of 5 × 2.5 × 2.5 cm, first polish it with 180-grit sandpaper, then polish it with 1000-grit sandpaper, clean the metal surface with ethanol, acetone, and distilled water in turn, and dry it naturally; use a concentration of 6mol / L sulfuric acid solution at 40°C to corrode the cleaned aluminum block for 1 min, rinse it with distilled water, and place it in the air to dry naturally; put the corroded aluminum block to dry at a temperature of Put the superhydrophobic aluminum block in a vacuum drying oven at 180°C for 16 hours under normal pressure and seal it; put the prepared superhydrophobic aluminum block in water at 100°C for 15 minutes, take it out, cool it, and dry it naturally. The superhydrophobic aluminum block becomes It is a superhydrophilic aluminum block. Repeated 180°C vacuum drying oven heat treatment and 100°C boiling water heat treatment operations can achieve repeated reversible conversion of superhydrophobic / sup...

Embodiment 3

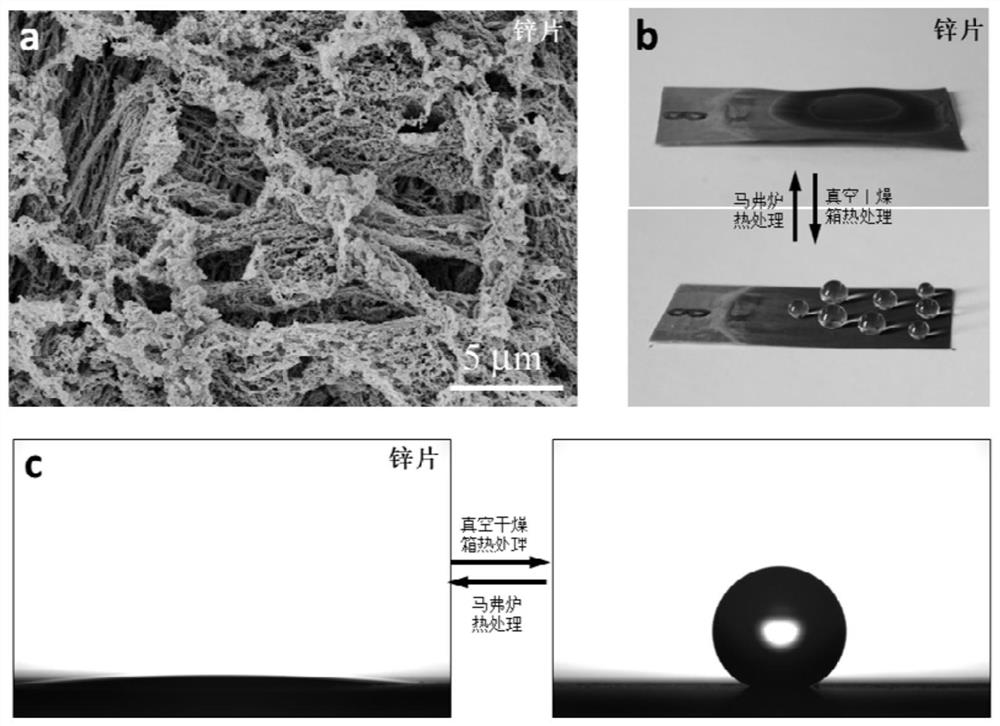

[0036] Cut out a zinc sheet with a size of 2×4×0.03cm, first polish it with 400-grit sandpaper, then polish it with 1000-grit sandpaper, wash the zinc sheet with ethanol, acetone, and distilled water in sequence, and dry it naturally; put the cleaned zinc sheet into The hydrochloric acid solution with a concentration of 4mol / L was corroded at 25°C for 60s, rinsed with distilled water, and placed in the air to dry naturally; put the corroded and dried zinc sheet at a temperature of 150°C The superhydrophobic zinc flakes were prepared by sealing and standing in a vacuum drying oven under normal pressure for 24 hours; the superhydrophobic zinc flakes were heated in a muffle furnace at 340 °C for 12 hours, and cooled naturally to room temperature, and the superhydrophobic zinc flakes transformed into superhydrophobic zinc flakes. Hydrophilic. Repeating the above-mentioned 150°C vacuum drying oven heat treatment and 340°C muffle furnace heat treatment operation can realize the repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com