Antenna fabrication method and antenna with same

An antenna and insulating substrate technology, which is applied to the antenna preparation method and the antenna field having the same, can solve the problems of long time consumption, complicated graphene antenna processing technology, high cost and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

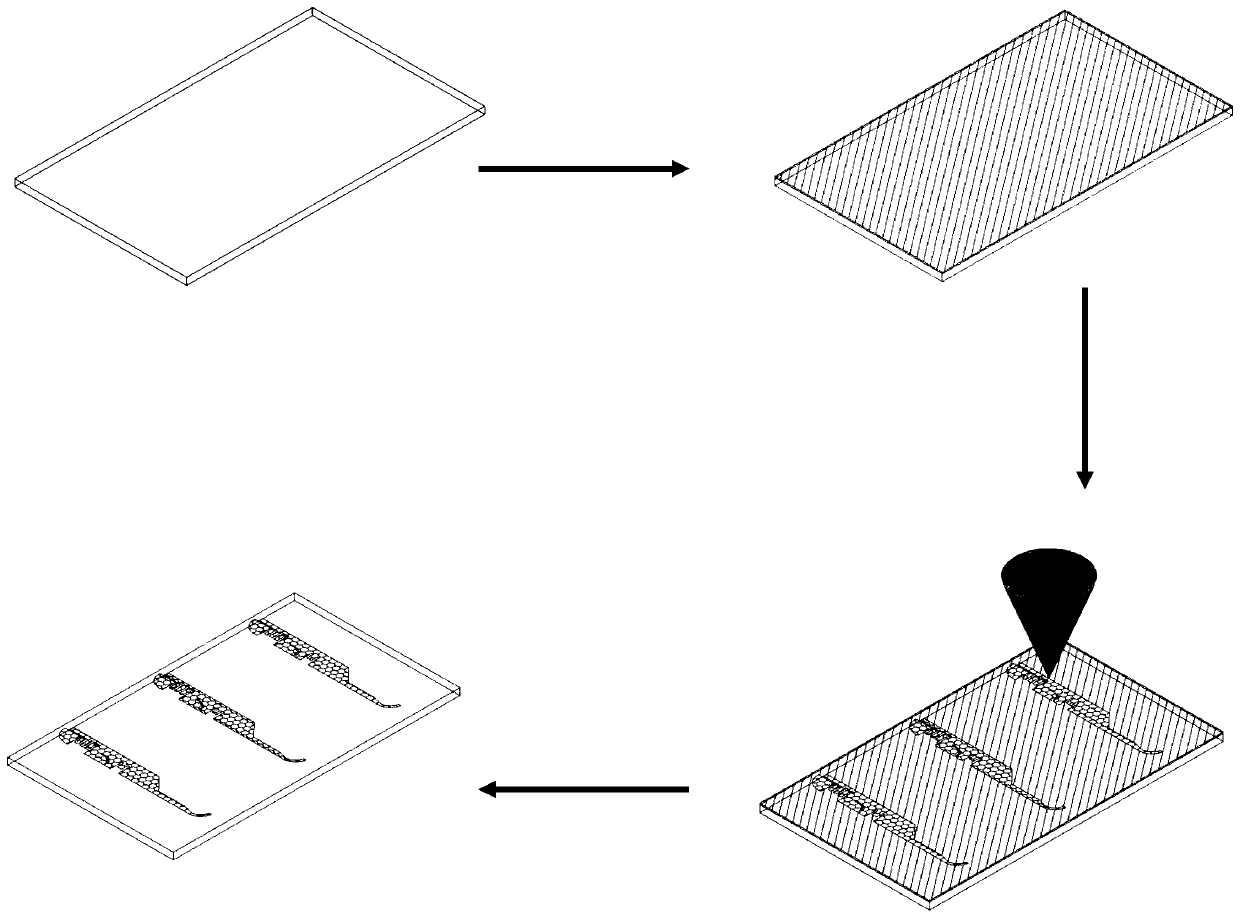

[0023] Provided is a method for preparing an antenna and an antenna having the same. The method belongs to the method of preparing antennas by adding materials, and is suitable for preparing antennas on planes and curved surfaces. Antennas with planar and curved structures can be prepared, and antennas with high flexibility can also be prepared. antenna. The same antenna as the preset pattern can be made in one step by laser direct writing, compared to growing graphene on a metal substrate in a vacuum environment, then transferring graphene from the metal substrate to a transparent substrate, and then using laser cutting to reduce the material The process for obtaining graphene target graphics is simple, low in cost, and resource-saving.

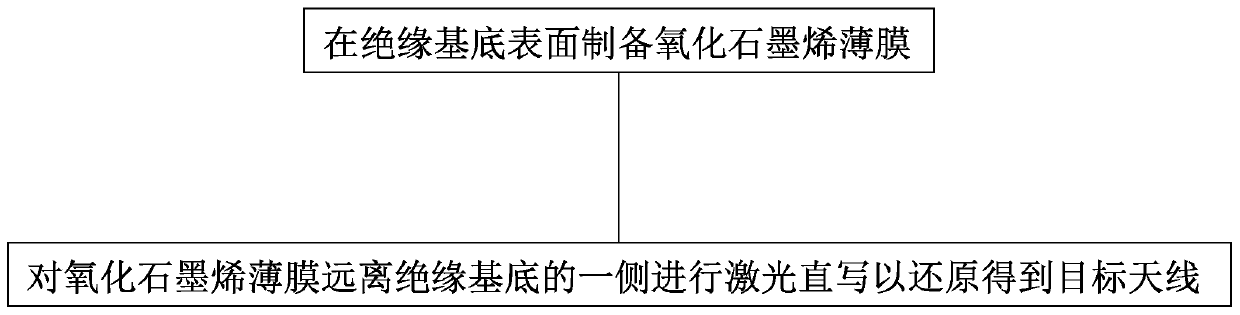

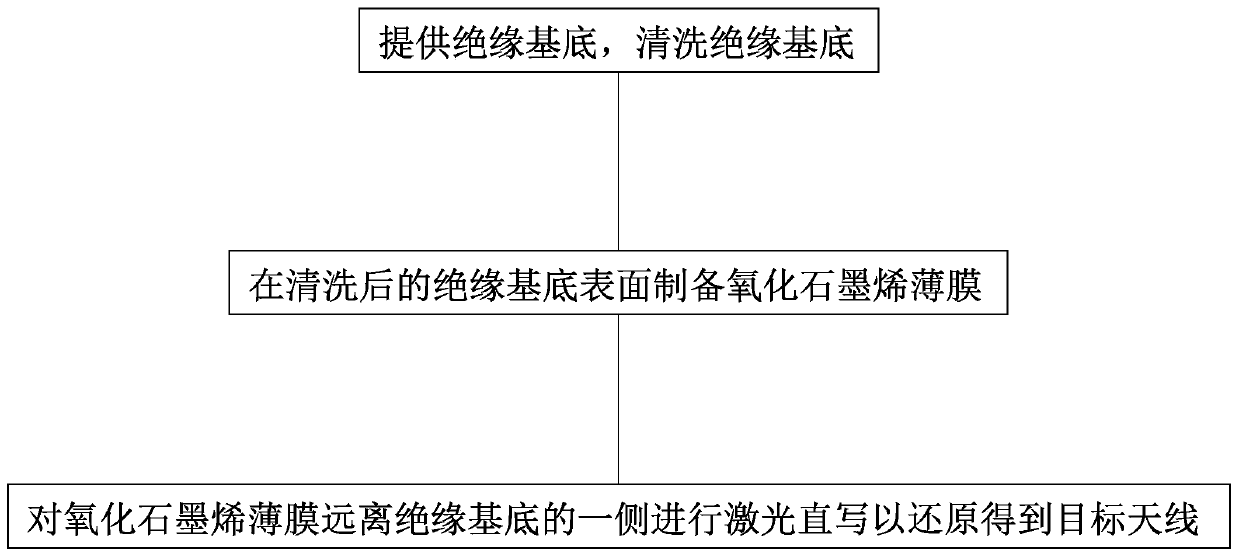

[0024] figure 1 Shown is a flow chart of the preparation process of the antenna provided by an embodiment of the present invention, figure 2 Shown is a flow chart of the antenna preparation process provided by another embodiment of the pr...

Embodiment 1

[0065] (1) Clean the glass insulating substrate with acetone, absolute ethanol, and deionized water in sequence to remove dust and oil on the surface of the glass insulating substrate, and then blow dry and dry the glass insulating substrate.

[0066] (2) adopt spin coating method, on the glass surface after cleaning, coat one deck graphene oxide solution;

[0067] (3) Place the above-mentioned coated glass on a hot plate at 90°C for 2 minutes and dry it for 2 minutes, and wait for it to solidify to form a stable film with a film thickness of 2 μm;

[0068] (4) Place the cured glass on the laser focal plane, control the movement of the laser beam with a scanning galvanometer, and write the preset antenna pattern directly on the glass surface. The laser output wavelength is 355nm, the laser output power is set to 1W, and the scanning speed is 100mm / s;

[0069] (5) After laser direct writing, put the glass in deionized water for ultrasonic / rinsing cleaning, remove the area not ...

Embodiment 2

[0071] (1) Clean the polyimide insulating base with isopropanone, absolute ethanol, and deionized water in sequence, remove the dust and oil on the surface of the polyimide insulating base, then blow dry and dry the polyimide insulating base ;

[0072] (2) adopt spraying method, in the polyimide insulation substrate surface after cleaning, coat one deck graphene oxide solution;

[0073] (3) Place the above-mentioned coated glass on a hot plate at 150°C and dry it for 50s, and wait for it to solidify to form a stable film with a film thickness of 50 μm;

[0074] (4) Place the above-mentioned polyimide insulating substrate on the laser focal plane, use a scanning galvanometer to control the movement of the laser beam, and directly write a preset antenna pattern on the surface of the polyimide insulating substrate. The laser output wavelength is 308nm, the laser output power is set to 10mW, and the scanning speed is 100mm / s;

[0075] (5) After laser direct writing, place the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com