Formula and preparation method of photocuring 3D printing haversian system artificial bone scaffold

A 3D printing and light-curing technology, applied in the medical field, can solve the problems of limited shape, difficult to control pore size and interconnection degree, solvent residue, etc., and achieve the effect of easy implementation and promotion, simple and convenient preparation process, and promotion of bone repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The formulation of the light-curing 3D printing Haversian system artificial bone scaffold listed in this example is made of the following raw materials:

[0036] Collagen (medical grade) 5%, normal saline 10%, nano-hydroxyapatite (medical grade) 43%, photosensitive resin (medical grade) 40%, photoinitiator 1%, dispersant 1%.

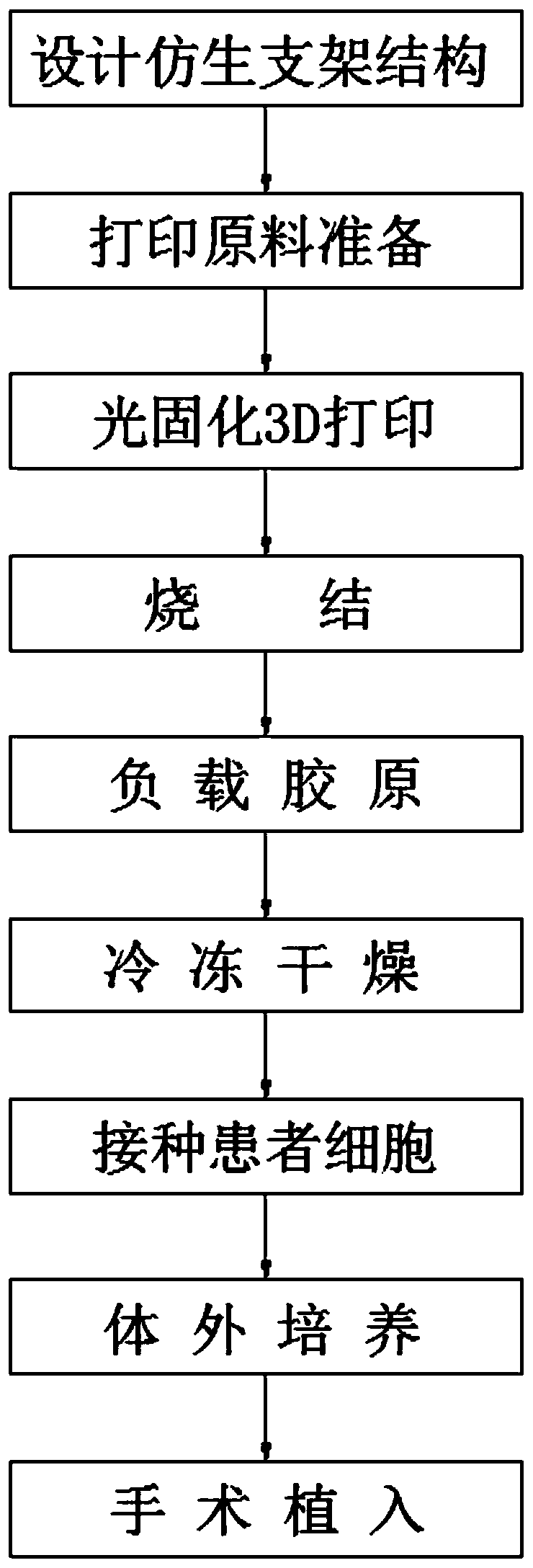

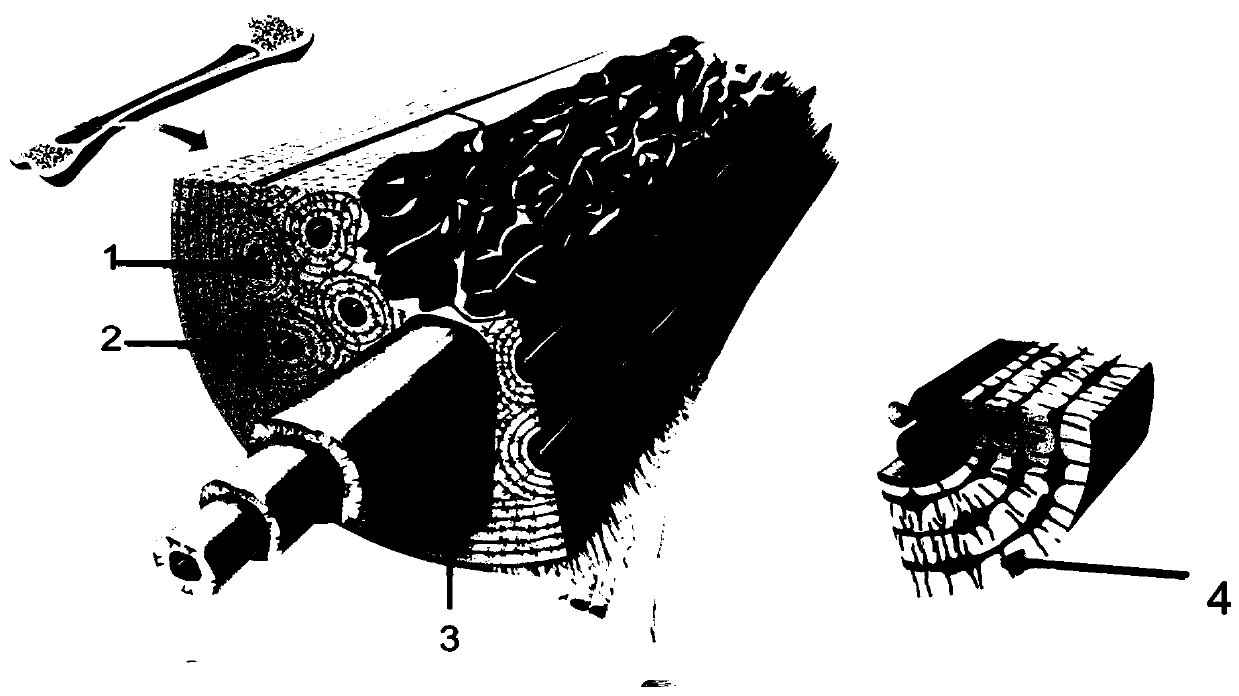

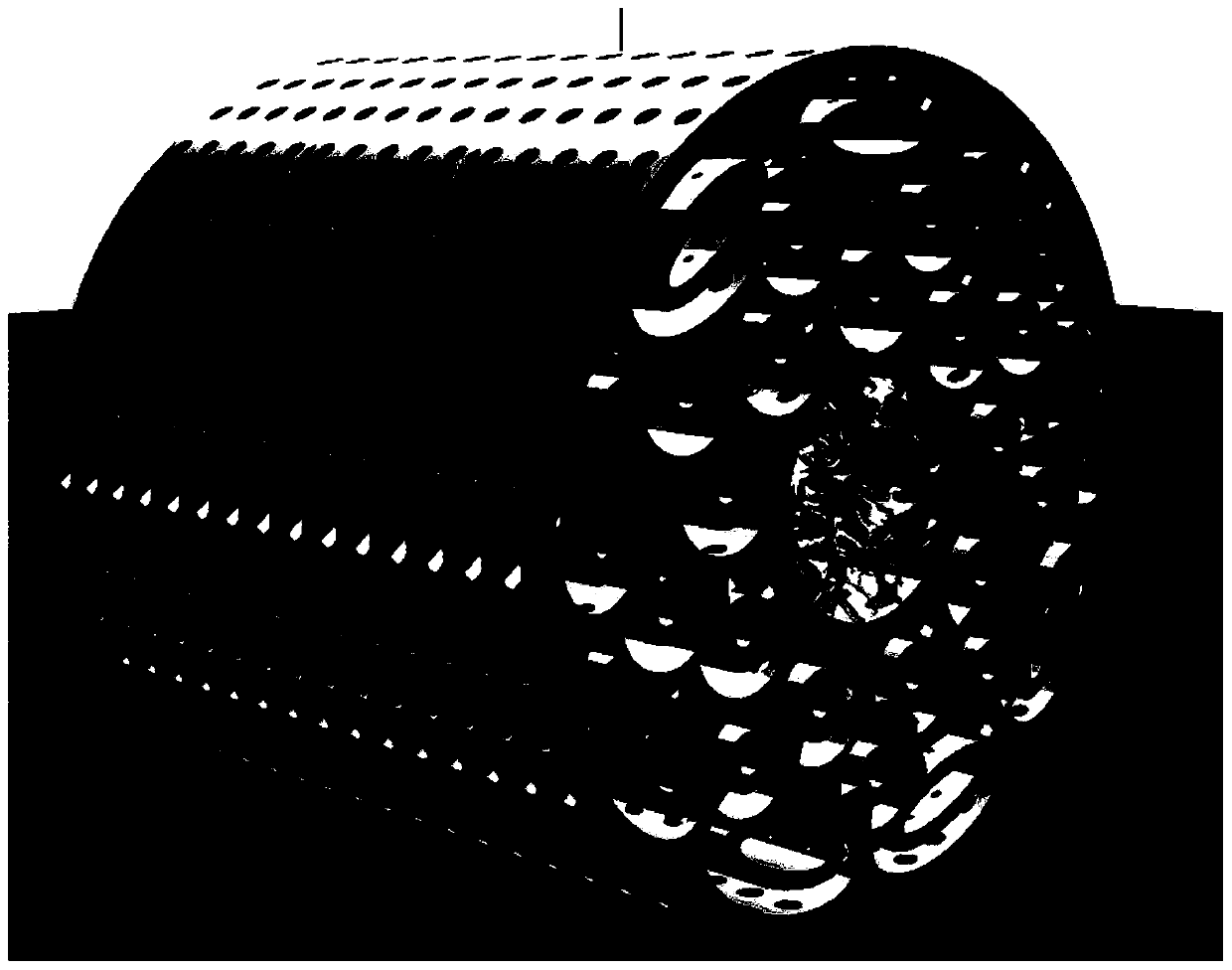

[0037]It is made according to the following method. Firstly, micro-CT scans the human bone metaphysis specimen (such as human distal femur or proximal tibia), obtains micro-CT data of human trabecular bone, reconstructs the structure of trabecular bone in 3D, and saves it as an STL file. , combining the reconstructed bone trabecular structure with the scaffold designed by the bionic Harvard tube system, that is, the central part is the bone trabecular structure, and the peripheral part is the Haversian tube system structure, and the STL file of the bionic artificial bone scaffold is obtained, and the nano-hydroxyapatite Stone (medical grade), phot...

Embodiment 2

[0040] The formulation of the light-curing 3D printing Haversian system artificial bone scaffold listed in this example is made of the following raw materials:

[0041] Collagen (medical grade) 3.5%, normal saline 7.5%, nano-hydroxyapatite (medical grade) 56.25%, photosensitive resin (medical grade) 30%, photoinitiator 0.75%, dispersant 2%.

[0042] It is made according to the following method. Firstly, micro-CT scans the human bone metaphysis specimen (such as human distal femur or proximal tibia), obtains micro-CT data of human trabecular bone, reconstructs the structure of trabecular bone in 3D, and saves it as an STL file. , combining the reconstructed bone trabecular structure with the scaffold designed by the bionic Harvard tube system, that is, the central part is the bone trabecular structure, and the peripheral part is the Haversian tube system structure, and the STL file of the bionic artificial bone scaffold is obtained, and the nano-hydroxyapatite Stone (medical gr...

Embodiment 3

[0045] The formulation of the light-curing 3D printing Haversian system artificial bone scaffold listed in this example is made of the following raw materials:

[0046] Collagen (medical grade) 5%, physiological saline 10%, nano-hydroxyapatite (medical grade) 61.5%, photosensitive resin (medical grade) 20%, photoinitiator 0.5%, dispersant 3%.

[0047] It is made according to the following method. Firstly, micro-CT scans the human bone metaphysis specimen (such as human distal femur or proximal tibia), obtains micro-CT data of human trabecular bone, reconstructs the structure of trabecular bone in 3D, and saves it as an STL file. , combining the reconstructed bone trabecular structure with the scaffold designed by the bionic Harvard tube system, that is, the central part is the bone trabecular structure, and the peripheral part is the Haversian tube system structure, and the STL file of the bionic artificial bone scaffold is obtained, and the nano-hydroxyapatite Stone (medical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com