Vanadium titanium magnetite tailings recleaning process

A vanadium-titanium magnetite and tailings technology, which is applied in the field of vanadium-titanium magnetite tailings re-election process, can solve the problem of affecting the price and sales, the recovery rate is difficult to exceed 20%, and it is difficult to obtain high-quality titanium concentrate Iron ore and iron concentrate and other issues, to achieve the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the technical means and effects of the present invention to solve the technical problems, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the scope of protection required by the present invention.

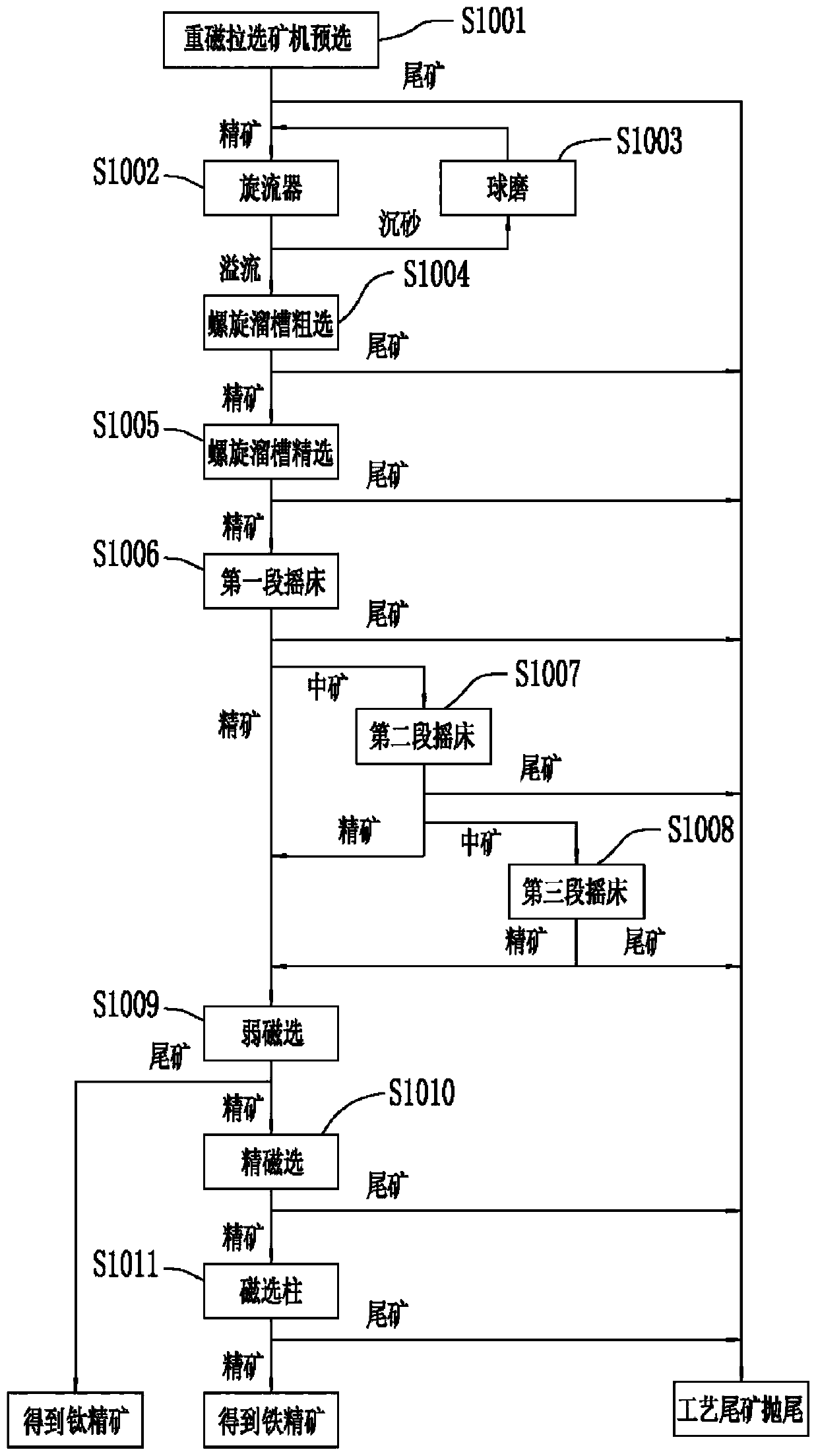

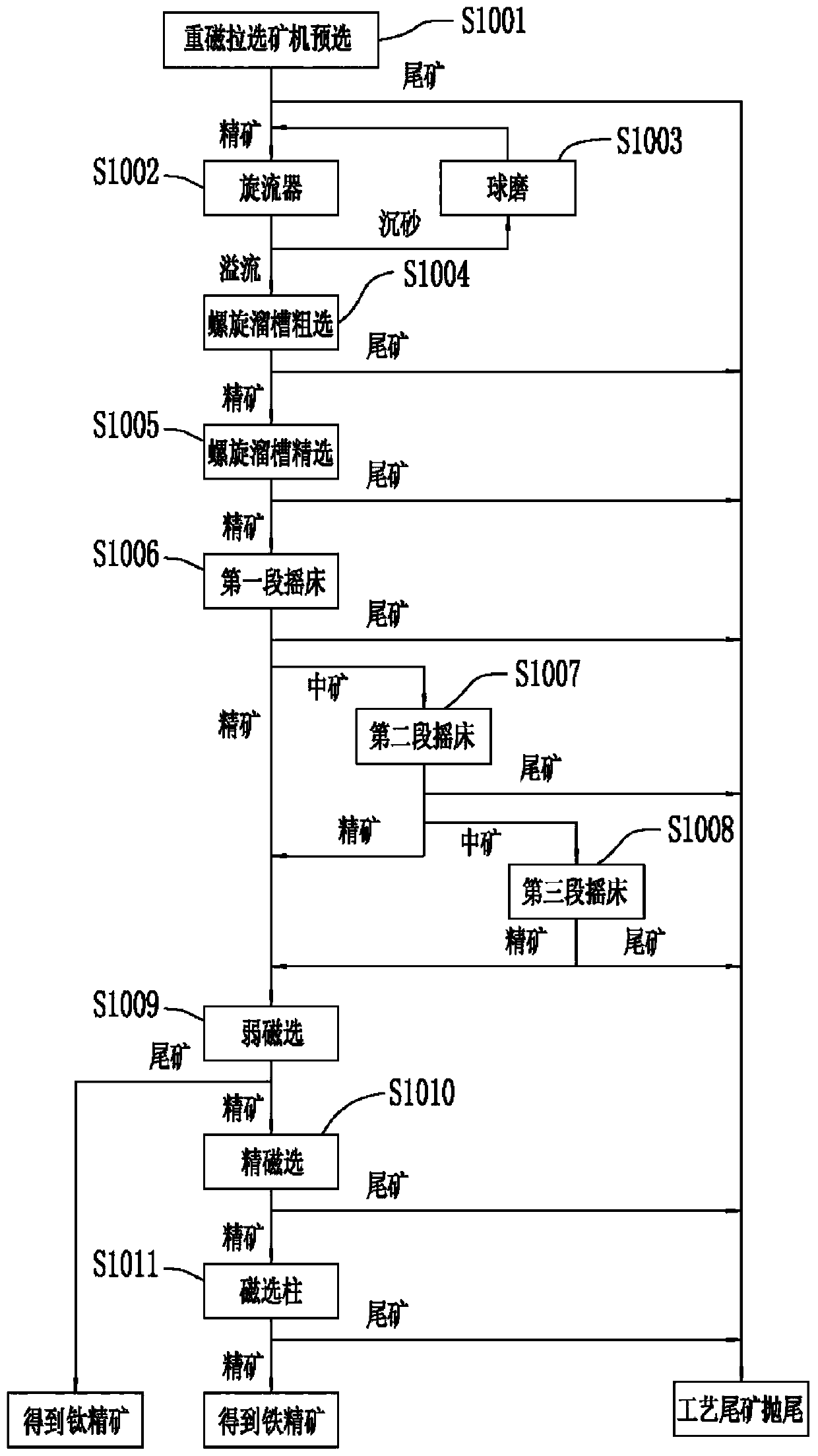

[0020] Such as figure 1 The process flow of the optional embodiment of the vanadium-titanium-magnetite tailings re-selection process shown includes the pre-selection S1001 of the gravity-magnetic pull separator, the closed circuit of the ball mill S1003 and the cyclone S1002, the rough selection of the spiral chute S1004, the selection of the spiral chute S1005, Three-stage shaker, weak magnetic separation S1009, fine magnetic separation S1010 and magnetic separation column S1011;

[0021] Vanadium-titanium magnetite tailings particle size is 0-1mm, Fe grade is 13.50%, TiO 2 The main components of useful minerals in vanadium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com