Sea-urchin-shaped gold nano particles and synthesis method thereof

A gold nanoparticle and synthesis method technology, applied in the field of sea urchin-shaped gold nanoparticle and its synthesis, to achieve the effects of good repeatability, strong shape controllability, and good application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A synthetic method of sea urchin-shaped gold nanoparticles, comprising the steps of:

[0021] (1) The required raw materials soluble silver source (silver nitrate), soluble gold source 1 (chloroauric acid), soluble gold source 2 (chloroauric acid) and weak reducing agent (ascorbic acid) were prepared into solutions using ultrapure water. Wherein, the concentration of soluble silver source (silver nitrate) solution is 0.1mol / L, the concentration of soluble gold source one (chloroauric acid) is 0.1mol / L, and the concentration of soluble gold source two (chloroauric acid) is 3mmol / L , the concentration of weak reducing agent (ascorbic acid) is 10mmol / L.

[0022] (2) Vigorously mix 2 μL soluble silver source (silver nitrate) solution and 2 μL soluble gold source-(chloroauric acid) solution in a glass bottle (the molar ratio of silver source to gold source-1 is 1:1), and quickly add 1mL of weak reducing agent (ascorbic acid) solution was vigorously stirred for 5s, then quic...

Embodiment 2

[0028] This embodiment is similar to Embodiment 1. The variables in Embodiment 1 are fixed and other variables are changed, including the following steps:

[0029] (1) The required raw materials soluble silver source (silver nitrate), soluble gold source 1 (chloroauric acid), soluble gold source 2 (chloroauric acid) and weak reducing agent (ascorbic acid) were prepared into solutions using ultrapure water. Wherein, the concentration of soluble silver source (silver nitrate) solution is 0.1mol / L, the concentration of soluble gold source one (chloroauric acid) is 0.1mol / L, and the concentration of soluble gold source two (chloroauric acid) is 3mmol / L respectively. L, the concentration of weak reducing agent (ascorbic acid) is 10mmol / L.

[0030] (2) Vigorously mix 2 μL soluble silver source (silver nitrate) solution and 8 μL soluble gold source-(chloroauric acid) solution in a glass bottle (the molar ratio of silver source to gold source-1 is 1:4), and quickly add 1mL of weak re...

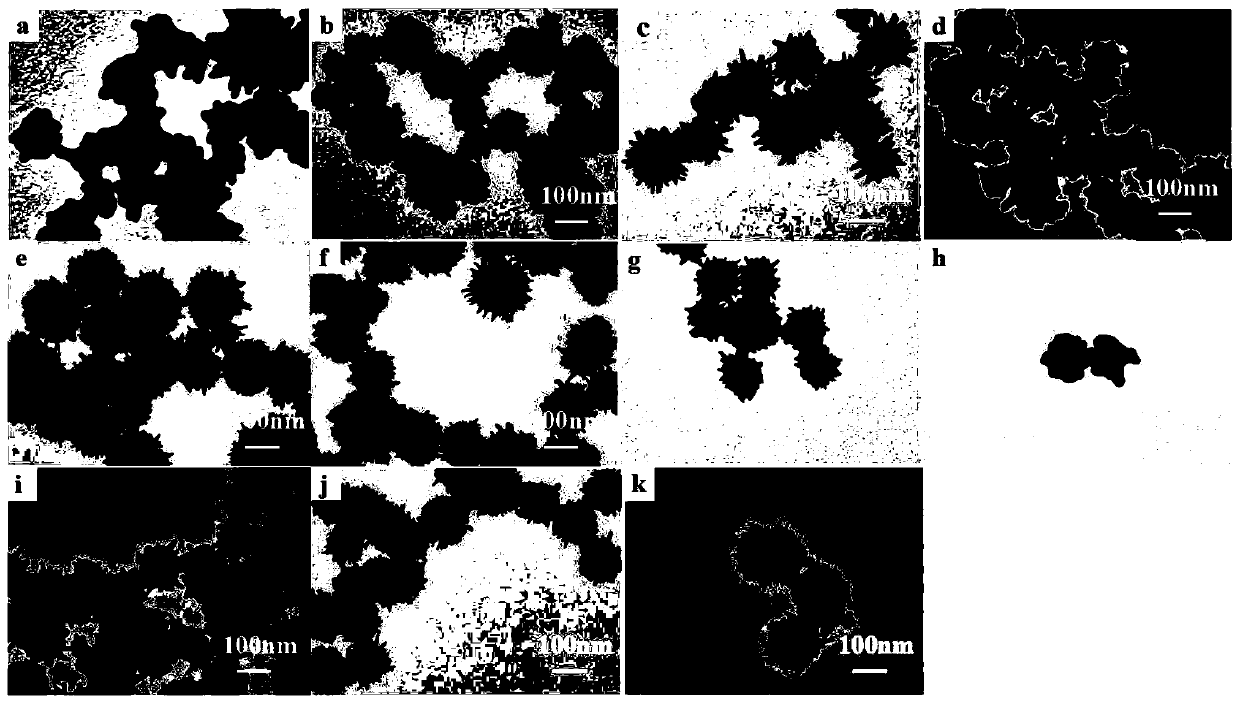

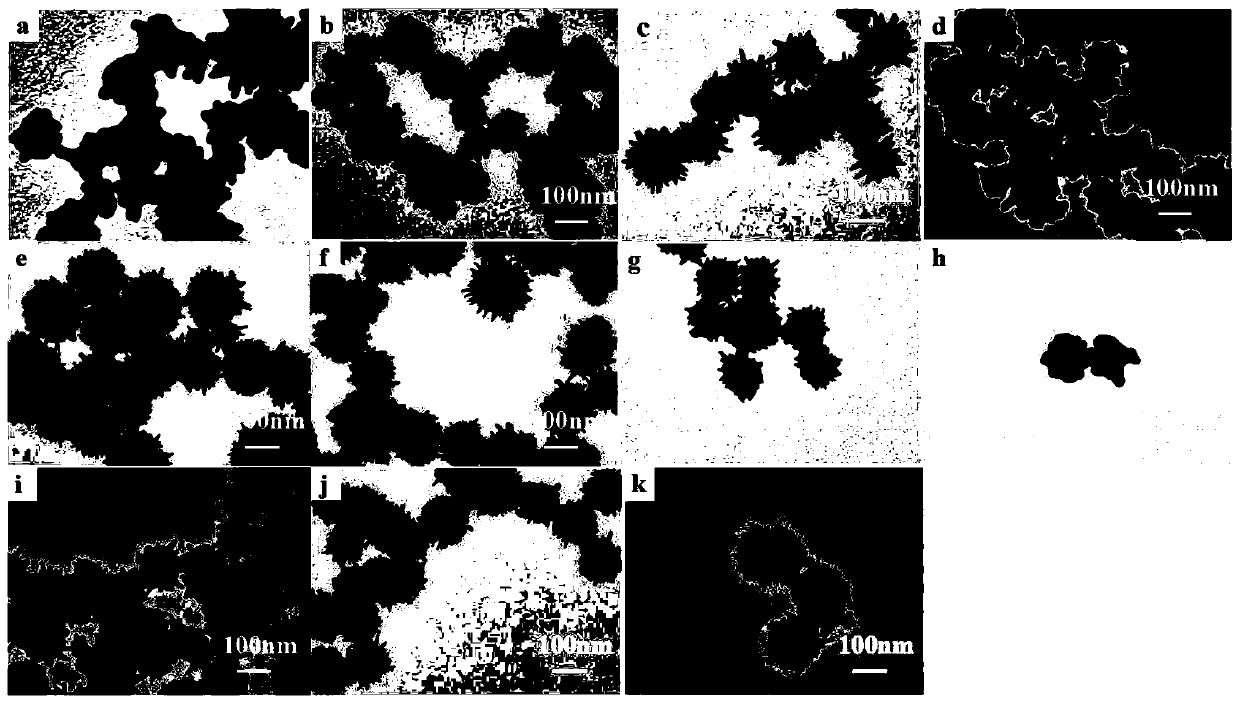

Embodiment 3

[0036] This embodiment is similar to Embodiment 1 and 2, fixing the variables in Embodiment 1 and 2, changing other variables, including the following steps:

[0037] (1) The required raw materials soluble silver source (silver nitrate), soluble gold source 1 (chloroauric acid), soluble gold source 2 (chloroauric acid) and weak reducing agent (ascorbic acid) were prepared into solutions using ultrapure water. Wherein, the concentration of soluble silver source (silver nitrate) solution is 0.1mol / L, the concentration of soluble gold source one (chloroauric acid) is 0.1mol / L, and the concentration of soluble gold source two (chloroauric acid) is 0mmol / L respectively L, 1mmol / L, 2mmol / L, 3mmol / L, 4mmol / L, the concentration of the weak reducing agent (ascorbic acid) is 10mmol / L.

[0038] (2) Vigorously mix 2 μL soluble silver source (silver nitrate) solution and 2 μL soluble gold source-(chloroauric acid) solution in a glass bottle (the molar ratio of silver source to gold source-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com