Processing method of cold extruded high wear-resistant bearing outer ring

A technology of bearing outer ring and processing method, applied in the field of bearing outer ring processing, can solve the problems of poor quality stability, long processing cycle, low dimensional accuracy, etc., and achieve the effects of less cutting amount, saving processing cycle, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

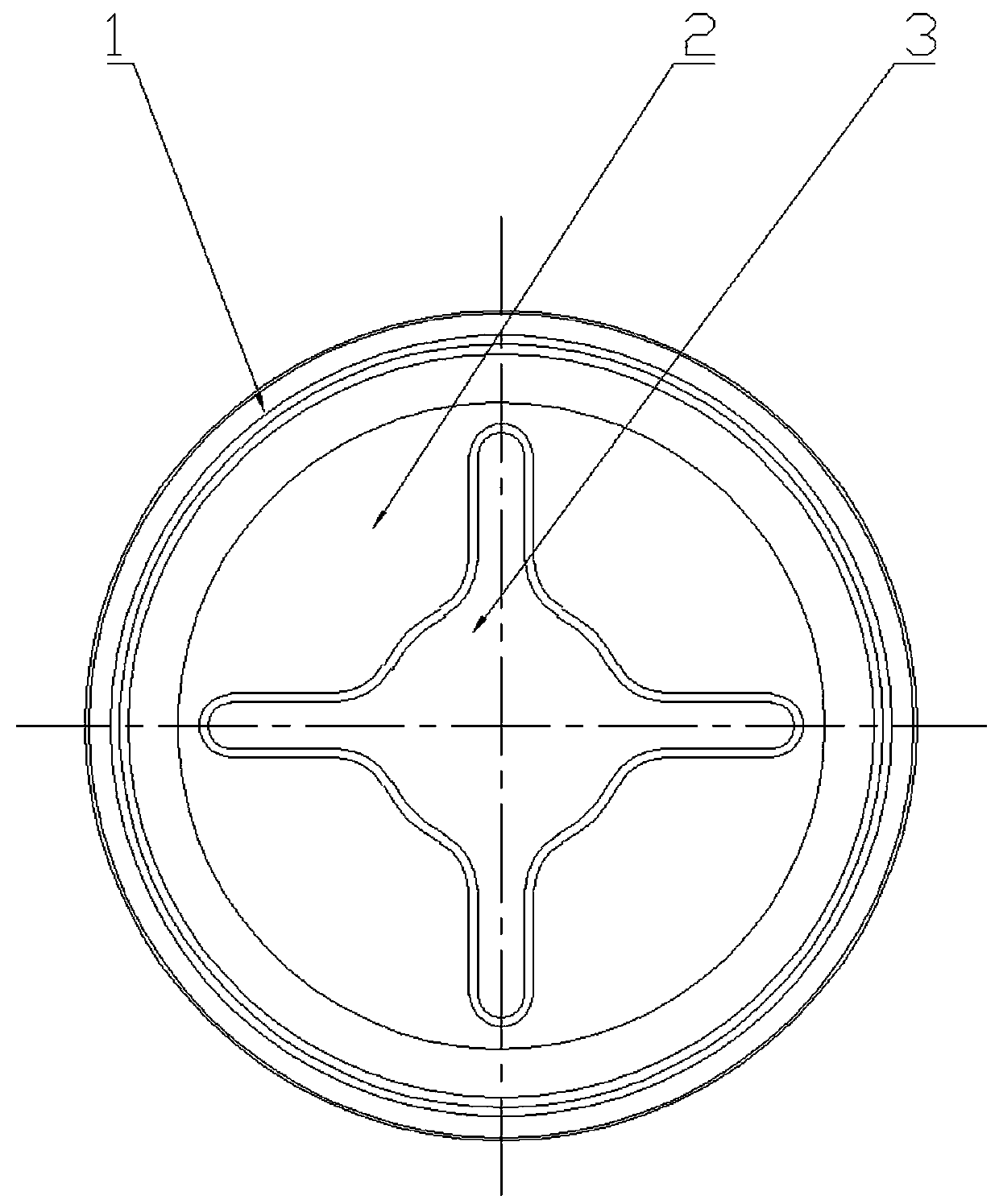

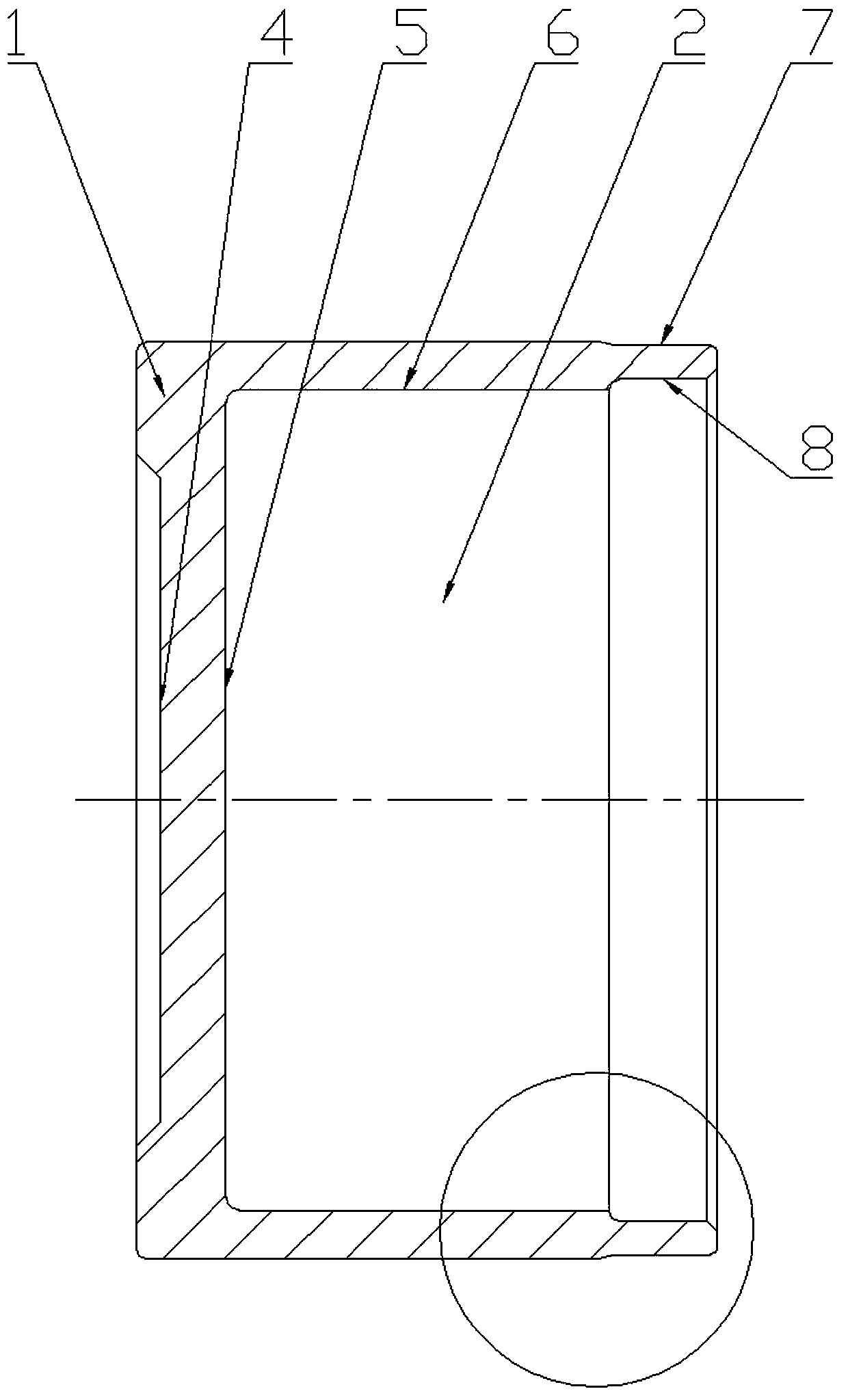

[0041] Example: such as Figure 1-8 As shown, a processing method for cold extruding a high wear-resistant bearing outer ring includes the following steps:

[0042] The first step: cut and blank the round steel by a shearing machine, and carry out spheroidizing annealing and softening treatment after being upset by the punching machine, and then the annealed workpiece is subjected to shot blasting, pickling, phosphating and saponification, and is sent by the punching machine The blank part 1 is formed by cold extrusion using a stamping mold.

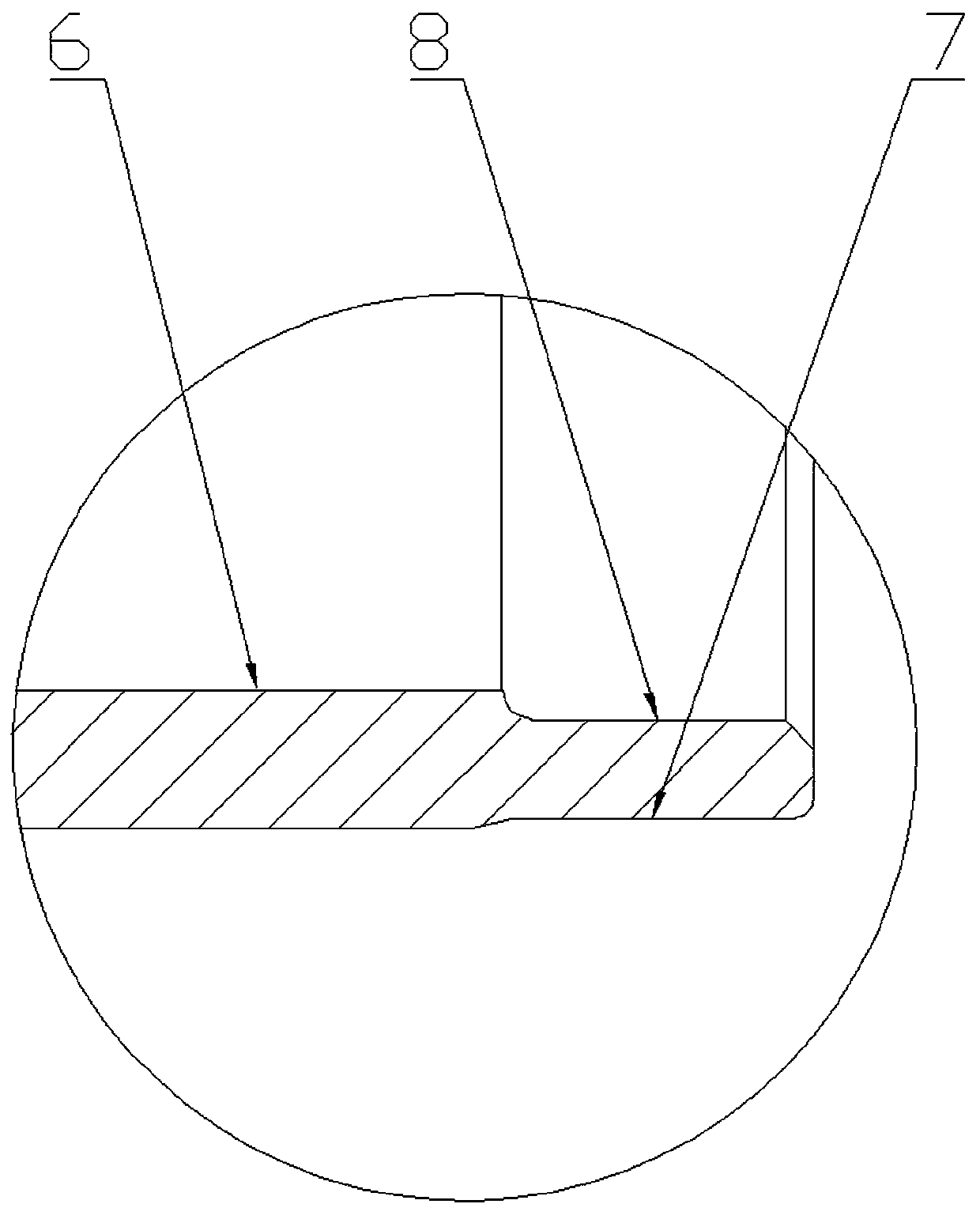

[0043]Second step: at this time, the blank 1 is firstly processed on the CNC lathe with the counterbore base surface 4 on the outer end surface 9 and the outer circle 10 as a reference, and the inner bottom surface 5 and the inner hole 6 are subjected to a one-time rough turning process. The inner bottom surface 5 and the inner hole 6 are fine-turned to the required size by using an inner hole turning tool. The inner hole step 8 is mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com