Method for synthesizing all-silicon ZSM-51 zeolite by seed crystal guiding method

A technology of ZSM-51 and guided method, which is applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of limiting the use of all-silicon ZSM-51 zeolite, achieve good reactivity, and simple synthesis operation Ease of operation, reduction of emissions and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Synthesis of all-silicon ZSM-51 zeolite by seed crystal method

[0021] 0.65g Na 2 SiO 3 9H 2 O, 1.50g of solid silica gel, 1.3g of ethanol and 0.017g of all-silicon ZSM-51 (accounting for 1% of the mass ratio of silicon dioxide in the silicon source) seeds are placed in a grinding mill, and then crystallized at 180°C for 1d to complete After crystallization, the product was suction filtered and dried to obtain the product. The molar ratio of each reaction raw material is as follows:

[0022] SiO 2 :Na 2 O: ethanol = 1:0.08:1.0

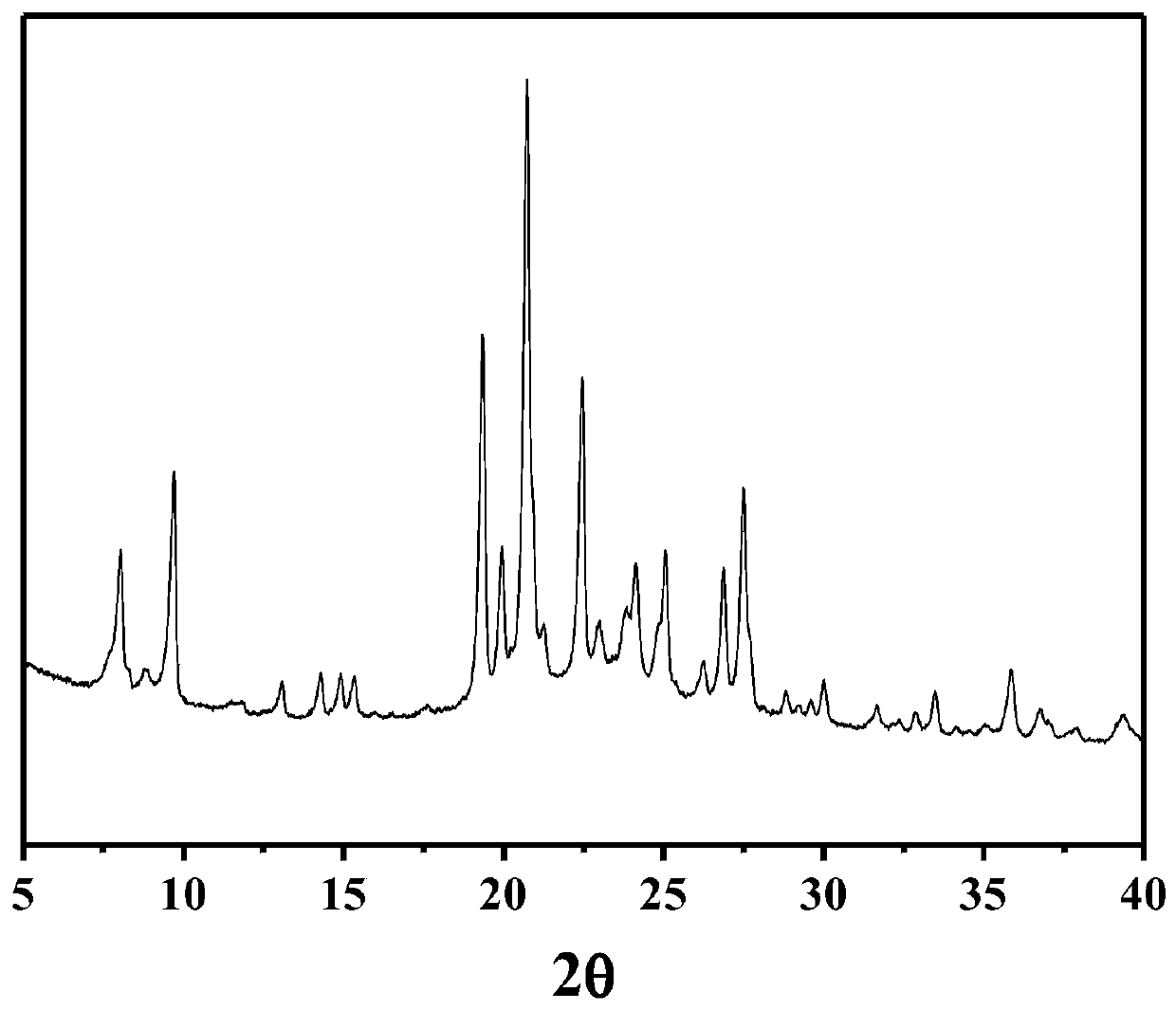

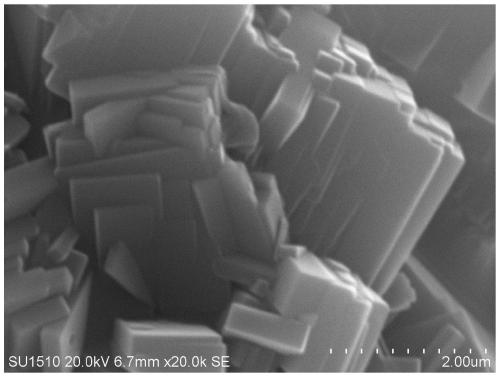

[0023] Obtained through XRD analysis its structure is all silicon ZSM-51 zeolite ( figure 1 ), and find out that the all-silicon ZSM-51 zeolite obtained by this method is a semi-cubic shape with a smooth surface ( figure 2 ).

Embodiment 2

[0024] Example 2: Synthesis of all-silicon ZSM-51 zeolite by seed crystal method at relatively high temperature

[0025] 0.47g Na 2 SiO 3 9H 2 O, 1.68g of solid silica gel, 2.5g of ethanol and 0.17g of all-silicon ZSM-51 (accounting for 10% of the mass ratio of silicon dioxide in the silicon source) seed crystals are placed in a grinding mill, and then crystallized at 200°C for 12h to complete After crystallization, the product was suction filtered and dried to obtain the product. The molar ratio of each reaction raw material is as follows:

[0026] SiO 2 :Na 2 O: ethanol = 1:0.06:2.0

Embodiment 3

[0027] Example 3: Synthesis of all-silicon ZSM-51 zeolite by seed crystal method at relatively low temperature

[0028] 0.95g Na 2 SiO 3 9H 2 O, 1.35g of solid silica gel, 1.9g of ethanol and 0.085g of all-silicon ZSM-51 (accounting for 5% of the mass ratio of silicon dioxide in the silicon source) seed crystals are placed in a grinding mill, and then crystallized at 160°C for 3 days to complete After crystallization, the product was suction filtered and dried to obtain the product. The molar ratio of each reaction raw material is as follows:

[0029] SiO 2 :Na 2 O: ethanol = 1:0.12:1.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com