Process for improving extraction rate of cannabidiol by treating flowers and leaves of Cannabis sativa by using microorganisms

A technology of microbial treatment and cannabidiol, which is applied in the preparation of organic compounds, bulk chemical production, chemical instruments and methods, etc., can solve the problems of limited transformation, achieve improved extraction rate, shorten extraction time, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

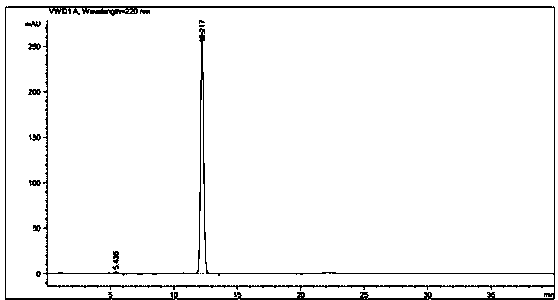

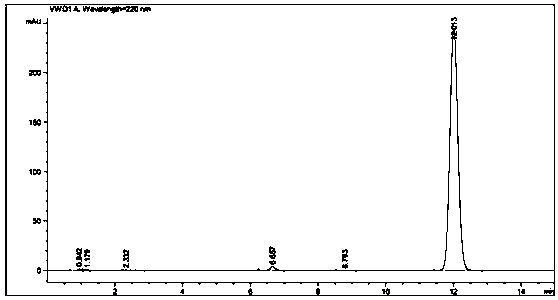

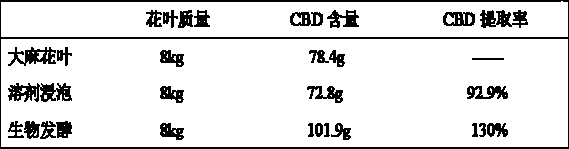

Image

Examples

Embodiment 1

[0019] 1) Pretreatment: Take the leaves, bark and root tissue of fresh cannabis plants that are growing well, and wash the stains on the surface with water. Wipe with 50% ethanol-water solution to kill bacteria on the tissue surface. Afterwards, it was washed with first-grade sterile water and dried in a sterile room for later use.

[0020] Be careful not to mix with diseased plant tissues, avoid bringing in other bad bacteria, and affect the culture of bacteria. Wipe with 50% ethanol solution, the surface of the tissue should be wet, and the tissue should not be soaked in the ethanol solution to prevent ethanol from penetrating into the tissue cells and killing intracellular fungi.

[0021] 2) Strain culture: Take the surface sterile and dry cannabis plant tissue, place it in a PDA plate medium in a sterile room, and culture it aseptically for 48 hours. Pick the white mycelium from the plate on the aseptic operating table, put it into the inclined surface of the test tube, ...

Embodiment 2

[0027] 1) Pretreatment: Take the leaves, bark and root tissue of a well-growing fresh cannabis plant, and wash the stains on the surface with water. Wipe with 50% ethanol-water solution to kill bacteria on the tissue surface. Afterwards, it was washed with first-grade sterile water and dried in a sterile room for later use. Be careful not to mix with diseased plant tissues, avoid bringing in other bad bacteria, and affect the culture of bacteria. Wipe with 50% ethanol solution, the surface of the tissue should be wet, and the tissue should not be soaked in the ethanol solution to prevent ethanol from penetrating into the tissue cells and killing intracellular fungi.

[0028] 2) Strain culture: Take the surface sterile and dry cannabis plant tissue, place it in a PDA plate medium in a sterile room, and culture it aseptically for 48 hours. Pick the white mycelium from the plate on the aseptic operating table, put it into the inclined surface of the test tube, and continue to c...

Embodiment 3

[0034]1) Pretreatment: Take the leaves, bark and root tissue of a well-growing fresh cannabis plant, and wash the stains on the surface with water. Wipe with 50% ethanol-water solution to kill bacteria on the tissue surface. Afterwards, it was washed with first-grade sterile water and dried in a sterile room for later use.

[0035] Be careful not to mix with diseased plant tissues, avoid bringing in other bad bacteria, and affect the culture of bacteria. Wipe with 50% ethanol solution, the surface of the tissue should be wet, and the tissue should not be soaked in the ethanol solution to prevent ethanol from penetrating into the tissue cells and killing intracellular fungi.

[0036] 2) Strain culture: Take the surface sterile and dry cannabis plant tissue, place it in a PDA plate medium in a sterile room, and culture it aseptically for 48 hours. Pick the white mycelium from the plate on the aseptic operating table, put it into the inclined surface of the test tube, and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com