Process method for extracting neophytadiene, carotenoid and nicotine from waste tobacco leaves

A new phytadiene, carotene technology, applied in chemical instruments and methods, hydrocarbon purification/separation, organic chemistry, etc., can solve the problems of low purity of new phytadiene, inability to industrially scale up production, and difficult industrial production. , to achieve the effect of high economic value, feasible operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Pulverize the waste tobacco leaves to 80-200 mesh, add 95% ethanol solution, extract by stirring at room temperature for 3 hours, and filter to obtain waste residue; add 95% ethanol to the remaining waste residue, repeat the above steps, and combine the two extracts to concentrate And reclaim ethanol, obtain the concentrated solution that density is 1.3;

[0034] (2) Add the concentrated solution in the step (1) to the extraction tank, and add an equal volume of ethyl acetate to extract;

[0035] (3) Concentrate the ethyl acetate extract in step (2) to 1 / 50 of the original volume, mix the sample with 100-200 mesh normal phase silica gel, and after the solvent evaporates to dryness, load the sample on the treated 200- 300 mesh normal phase silica gel column;

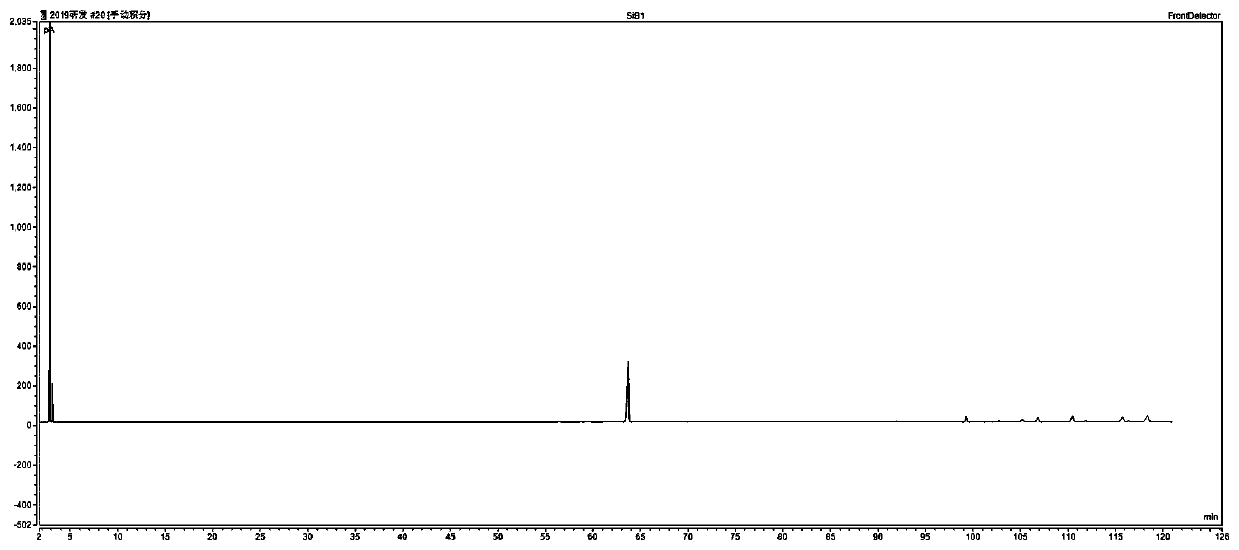

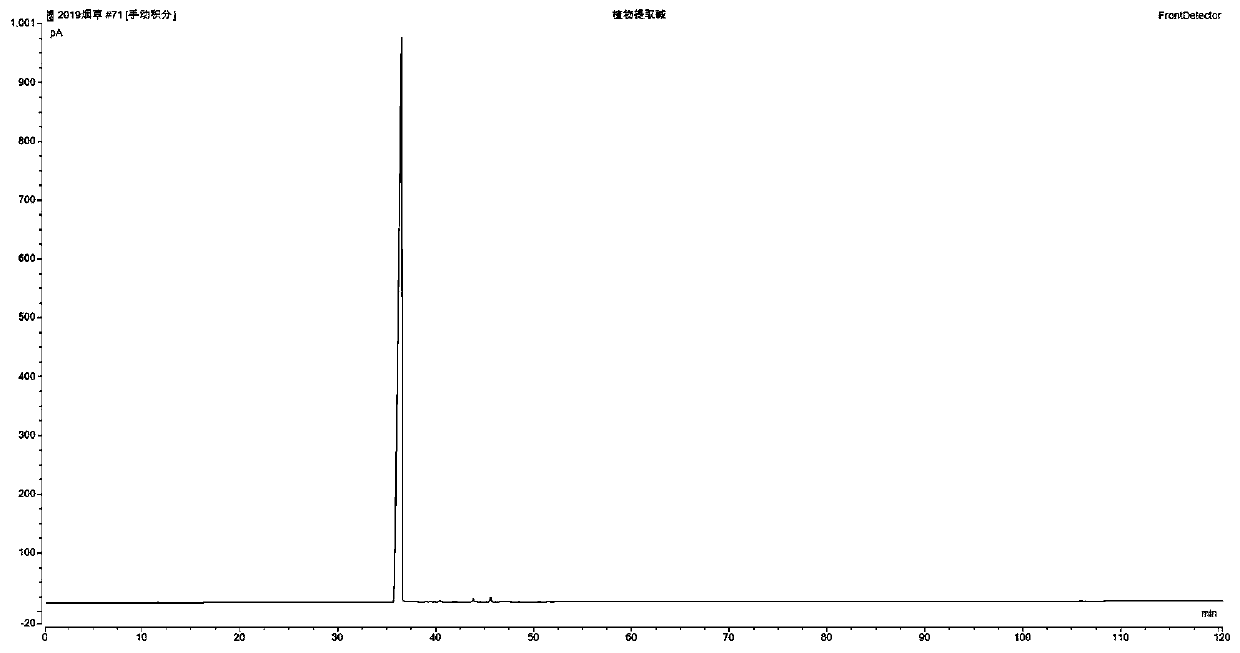

[0036] (4) Use n-pentane to elute the normal-phase silica gel column in step (3), collect the eluate, and concentrate the eluate to obtain crude neophytadiene, continue to use 8:1 petroleum ether and ethyl ace...

Embodiment 2

[0044] (1) Pulverize the discarded tobacco leaves to 80 mesh, add 95% ethanol solution, extract by stirring at room temperature for 4 hours, and filter to obtain waste residue; add 95% ethanol to the remaining waste residue, repeat the above steps, combine the two extracts to concentrate and recover Ethanol to obtain a concentrated solution with a density of 1.3;

[0045] (2) Add the concentrated solution in the step (1) to the extraction tank, and add an equal volume of ethyl acetate to extract;

[0046] (3) Concentrate the ethyl acetate extract in step (2) to 1 / 50 of the original volume, mix the sample with 100-200 mesh normal phase silica gel, and after the solvent evaporates to dryness, load the sample on the treated 300-400 normal phase silica gel column;

[0047] (4) Use n-pentane to elute the normal-phase silica gel column in step (3), collect the eluate, and concentrate the eluate to obtain crude neophytadiene, continue to use 8:1 petroleum ether and ethyl acetate to ...

Embodiment 3

[0051] (1) Pulverize the discarded tobacco leaves to 80 mesh, add 95% ethanol solution, extract by stirring at room temperature for 6 hours, and filter to obtain waste residue; add 95% ethanol to the remaining waste residue, repeat the above steps, combine the two extracts to concentrate and recover Ethanol to obtain a concentrated solution with a density of 1.3;

[0052] (2) Add the concentrated solution in the step (1) to the extraction tank, and add an equal volume of ethyl acetate to extract;

[0053] (3) Concentrate the ethyl acetate extract in step (2) to 1 / 50 of the original volume, mix the sample with 100-200 mesh normal phase silica gel, and after the solvent evaporates to dryness, load the sample on the treated 300-400 normal phase silica gel column;

[0054] (4) Use n-pentane to elute the normal-phase silica gel column in step (3), collect the eluate, and concentrate the eluate to obtain crude neophytadiene, continue to use 8:1 petroleum ether and ethyl acetate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com