Preparation method of durable polybutylene succinate

A technology of polybutylene succinate and butanediol, which is applied in the polymer field and achieves the effects of good thermal stability, low content of terminal carboxyl groups, and low alkyd molar ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

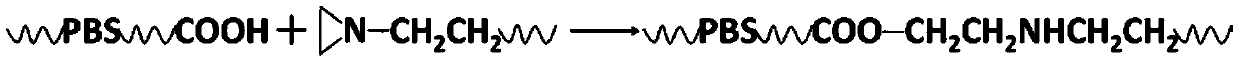

Method used

Image

Examples

Embodiment 1

[0035] Add 9.9kg of 1,4-butanediol, 11.8kg of succinic acid and 34.4g of composite homogeneous catalyst to the reaction kettle in sequence. Cooling and extruding, during extrusion, inject 344g of pentaerythritol tris(3-aziridinyl)propionate through a pump to obtain polymer A1, with a molecular weight of 115,000 and a carboxyl-terminated content of 8mmol / kg.

[0036] The preparation process of the composite homogeneous catalyst is to add titanium dioxide and zirconium dioxide to 1,4-butanediol in sequence, stir at 60°C for 15 minutes, add 2-methylimidazole, raise the temperature to 120°C, and stir for 50 minutes to obtain a composite type Homogeneous catalyst, the molar ratio of 1,4-butanediol, 5000 mesh titanium dioxide, 5000 mesh zirconium dioxide and 2-methylimidazole is 30:3:2:3.

Embodiment 2

[0040] Add 9.45kg of 1,4-butanediol, 11.8kg of succinic acid and 17.2g of composite homogeneous catalyst to the reaction kettle in sequence. Cooling and extruding, during extrusion, inject 86g of carboxyl end-capping agent trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate by pump to obtain polymer B1, molecular weight is 103,000 , the carboxyl-terminal content is 10mmol / kg.

[0041] The preparation process of the composite homogeneous catalyst is to add titanium dioxide and zirconium dioxide to 1,4-butanediol in sequence, stir at 40°C for 30 minutes, add 1-ethylimidazole, raise the temperature to 140°C, and stir for 40 minutes to obtain a composite type Homogeneous catalyst, the molar ratio of 1,4-butanediol, 8000 mesh titanium dioxide, 8000 mesh zirconium dioxide and 1-ethylimidazole is 20:3:2:3.

Embodiment 3

[0045] Add 10.35kg of 1,4-butanediol, 11.8kg of succinic acid and 1.72g of composite homogeneous catalyst to the reaction kettle in sequence. Cooling is extruded, and when extruding, inject carboxyl end-blocking agent 17.2g trimethylolpropane-tris(3-aziridinyl) propionate by pump, obtain polymer C1, molecular weight is 101,000, and carboxyl-terminated content is 15mmol / kg.

[0046] The preparation process of the composite homogeneous catalyst is to add titanium dioxide and zirconium dioxide to 1,4-butanediol in sequence, stir at 50°C for 15 minutes, add 2-propylimidazole and 4-methylimidazole, and heat up to 130°C. Stir for 50 minutes to obtain a composite homogeneous catalyst. The molar ratio of 1,4-butanediol, 10,000 mesh titanium dioxide, 10,000 mesh zirconia, 2-propylimidazole, and 4-methylimidazole is 10:3:2:2 :1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com