Hydrophobic liquid injection aluminum alloy surface with liquid storage tank and preparation method thereof

A technology of aluminum alloy surface and liquid storage tank, applied in surface reaction electrolytic coating, anodizing, electrolytic coating, etc., can solve problems such as no patent reports, and achieve the effect of high processing efficiency and increased storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

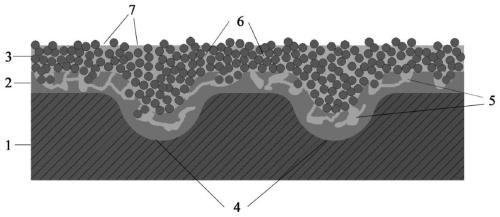

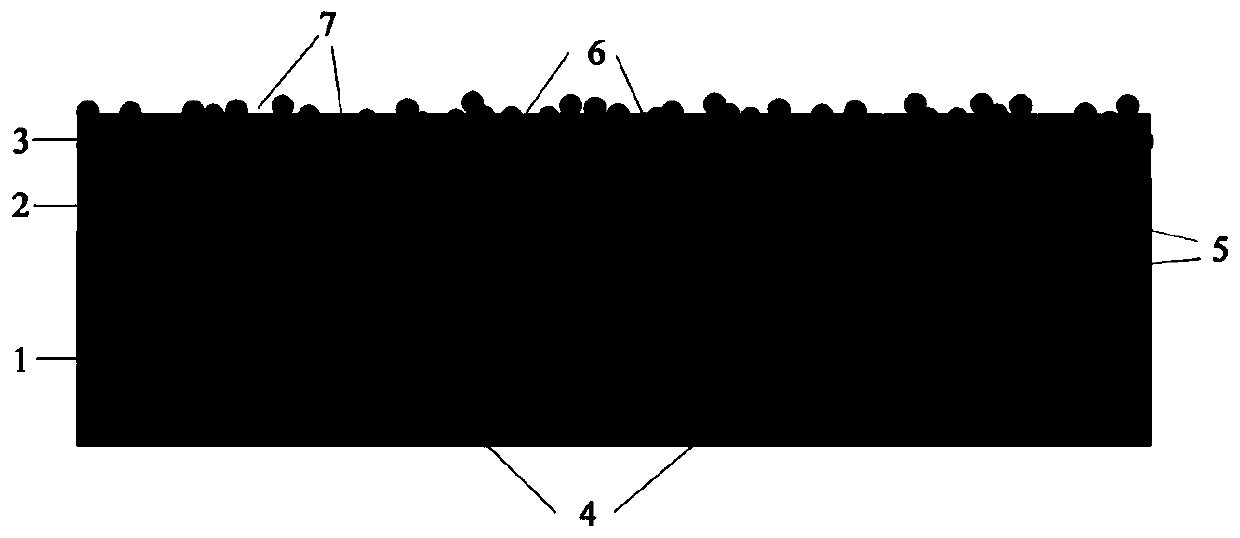

[0033] Such as figure 1 As shown, a hydrophobic liquid-injected aluminum alloy surface with a liquid reservoir includes an aluminum alloy substrate 1, on which a micro-arc oxidation coating 2 and a hydrophobic SiO 2 The nanoparticle sprayed layer 3; the aluminum alloy substrate 1 is etched with laser-etched micropores 4, the micro-arc oxidation coating 2 contains micro-arc oxidation self-generated micropores 5, hydrophobic SiO 2 The nanoparticle spray layer 3 contains nanoscale pores 6, and the laser-etched micropores 4, micro-arc oxidation self-generated micropores 5, and nanoscale pores 6 are connected to each other to form a liquid storage pool; perfluoropolyether oil is injected into it to form Perfluoropolyether oil is injected into layer 7.

Embodiment 2

[0035] Prepare a hydrophobic liquid injection surface with a liquid reservoir on 6061 aluminum alloy, the specific steps are as follows:

[0036](1) After the 6061 aluminum alloy substrate sample is polished step by step with 400-mesh and 600-mesh sandpaper, it is placed on the laser processing platform, and the micropore diameter is set to 150 μm and the transverse distance l is set by software. 1 and longitudinal spacing l 2 Both are 300μm, single-point laser etching 15 times at 15kHz laser beam processing frequency;

[0037] (2) After polishing the laser-etched surface with 1000-grit sandpaper, it was cleaned by ultrasonic oscillation for 10 minutes, and the depth of the laser-etched micropores measured by three-dimensional morphology was 50 μm;

[0038] (3) Weigh 12g sodium tripolyphosphate and 0.2g sodium hydroxide, dissolve in a stainless steel electrolytic cell filled with 1000mL deionized water, then immerse the polished laser-etched aluminum alloy sample in the elect...

Embodiment 3

[0044] Prepare a hydrophobic liquid injection surface with a liquid reservoir on 5083 aluminum alloy, the specific steps are as follows:

[0045] (1) After the 5083 aluminum alloy substrate sample was polished step by step with 400-mesh and 600-mesh sandpaper, it was placed on the laser processing platform, and the micropore diameter was set to 200 μm and the transverse spacing l 1 and longitudinal spacing l 2 Both are 200μm, single-point laser etching 10 times at 10kHz laser beam processing frequency;

[0046] (2) After polishing the laser-etched surface with 1000-grit sandpaper, it was cleaned by ultrasonic oscillation for 20 minutes, and the depth of the laser-etched micropores measured by three-dimensional morphology was 20 μm;

[0047] (3) Weigh 14g sodium tripolyphosphate and 0.6g sodium hydroxide, dissolve in a stainless steel electrolytic cell filled with 1000mL deionized water, then immerse the polished laser-etched aluminum alloy sample in the electrolyte as an anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com