Novel sisal/synthetic fiber composite structure oil-containing steel wire rope core and preparation method thereof

A composite structure and steel wire rope technology, applied in yarn, textile cable, transportation and packaging, etc., can solve problems such as many burrs on the surface of the rope core, increase production cost, affect production efficiency, etc., achieve low cost, reduce loss, and facilitate processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

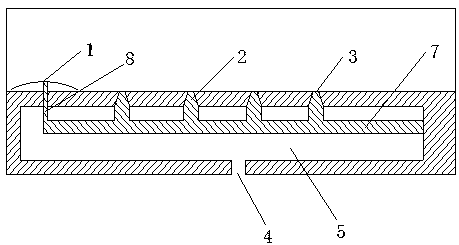

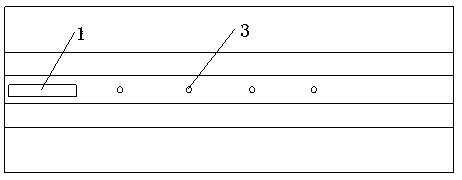

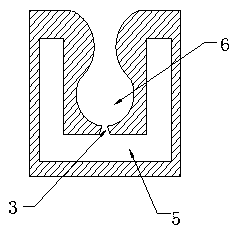

Method used

Image

Examples

Embodiment

[0041] The production process of a new sisal / synthetic fiber composite structure oil-containing steel wire rope rope core in the present invention is as follows: picking hemp→combing hemp (adding water)→drawing→spinning (adding oil)→winding warp→twisting strands (adding oil) → Twist the rope → Storage. Among them: the equipment models of each process: four lines of hemp, the models are L1 / 2, L3 / 4 respectively; five lines of drawing, respectively B1 / 2, B3, B4, B4; the spinning machine model is TGS0950; thread making The machine model is T1175, and the rope making machine model is M400. The specific operation is as follows:

[0042] The preparation method of described novel sisal / synthetic fiber composite rope core comprises the steps:

[0043] Step 1. Formation of sisal / polyester filament sirofield yarn: firstly pick up the sisal fiber, then go through four combing and five drawing frames, and then spin;

[0044] In the described spinning, the model of the spinning machine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com