Sealed circulating flow heat exchange and cooling system for granary and cooling method thereof

A technology of granary and heat exchange plate, applied in the fields of botanical equipment and method, fruit hanging device, gardening, etc., can solve the problems such as the inability to form a low-temperature cold core, the inability of warehousing enterprises to bear economic losses, and the reduction of grain temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

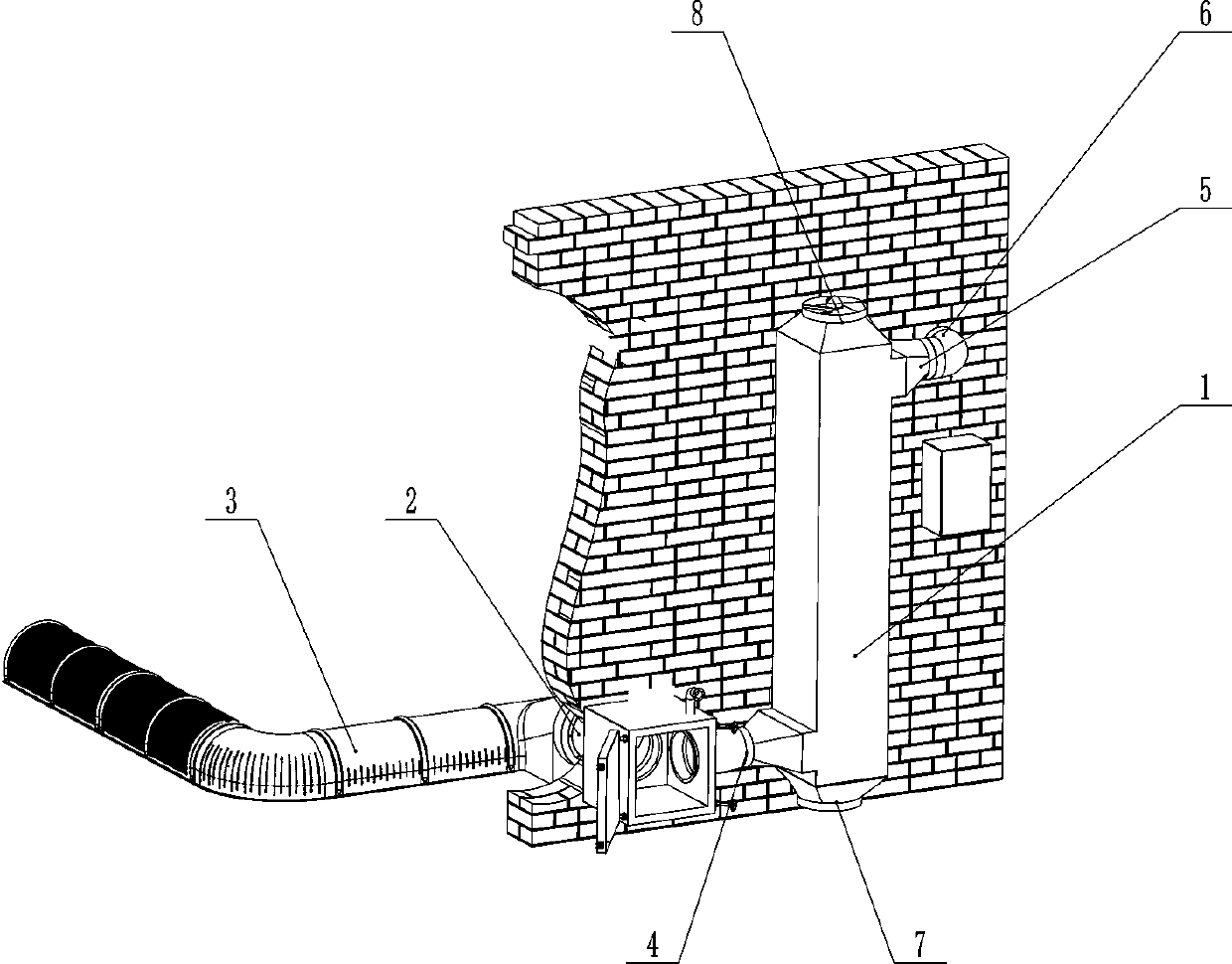

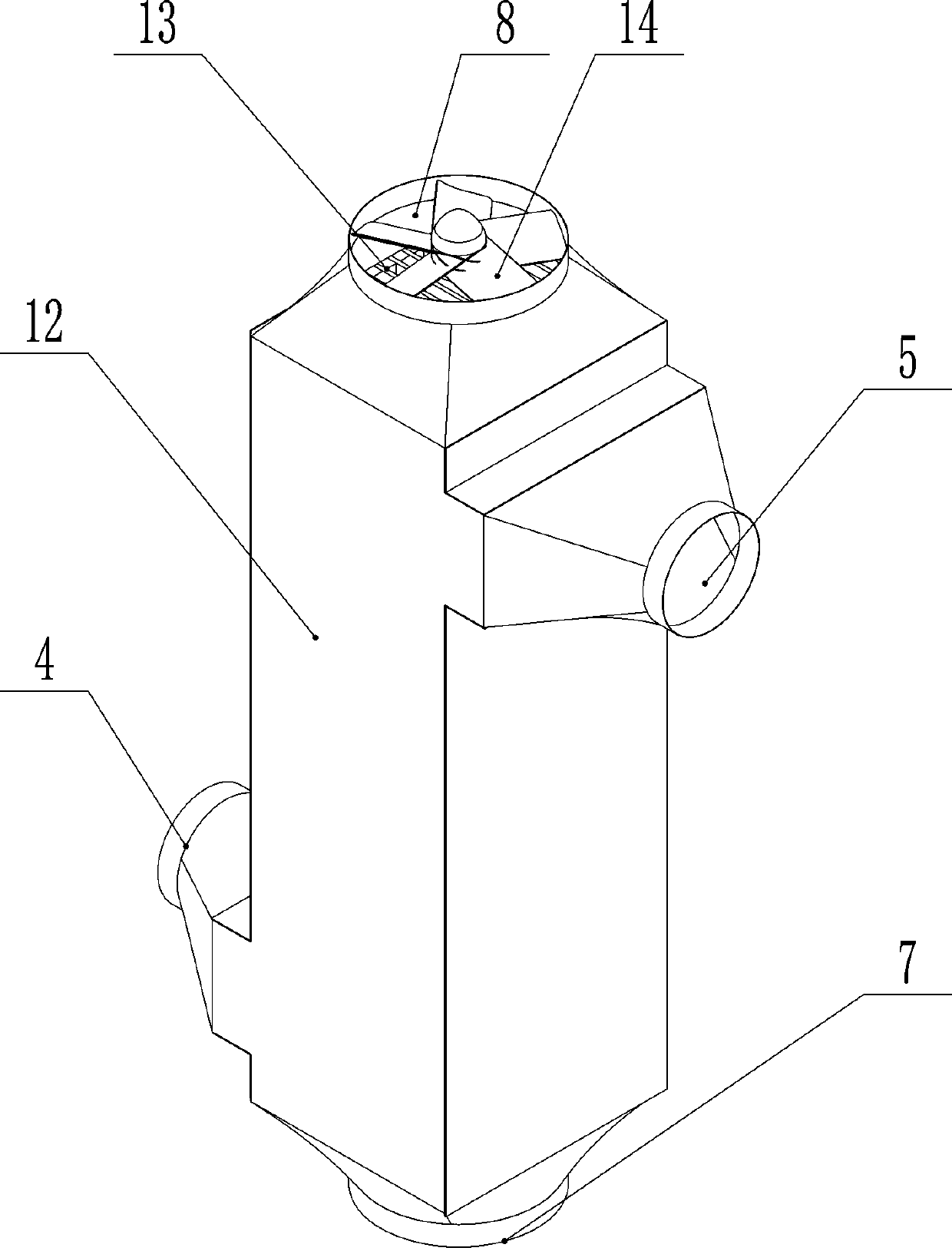

[0039] Such as figure 1 As shown, a granary closed loop heat exchange and cooling system includes a heat exchanger 1 installed on the outer wall of the granary, a ventilator 2 and an internal ventilation pipe network of the granary; the internal ventilation pipe network of the granary includes a ventilation cage 3, and the The outlet of the ventilation cage 3 is in sealing communication with the fan, and the fan is in sealing communication with the hot air inlet 4 of the heat exchanger 1 .

[0040] The hot air outlet 5 of the heat exchanger is connected to the interior of the granary through the hot air outlet connecting pipe 6 to form a closed circulation channel for hot air in the granary isolated from the outside world; the cold air inlet 7 and the cold air outlet 8 of the heat exchanger 1 are respectively It communicates with the atmosphere to form an atmospheric cold air passage isolated from the closed circulation passage of the granary hot air.

[0041] This embodiment...

Embodiment 2

[0051] In order to solve the cooling problem of controlled atmosphere storage in winter without changing the concentration of nitrogen or carbon dioxide gas in controlled atmosphere, it can be realized by the closed circulation heat exchange and cooling system of this granary. After the grain is stored, several grain surface ventilation pipes are laid at 10cm-20cm below the top grain surface. The length of the grain surface ventilation pipes is close to the span of the granary. Form an air inlet, which is connected to the hot air outlet of the heat exchanger through the hot air outlet connecting pipe, cover the grain surface with a plastic film to seal the grain surface, and finally replace the air in the granary with nitrogen or carbon dioxide, and seal it when the concentration meets the requirements Grain silos and grain piles realize controlled atmosphere storage.

[0052] In winter, to cool down the grain stored under controlled atmosphere, the nitrogen or carbon dioxide ...

Embodiment 3

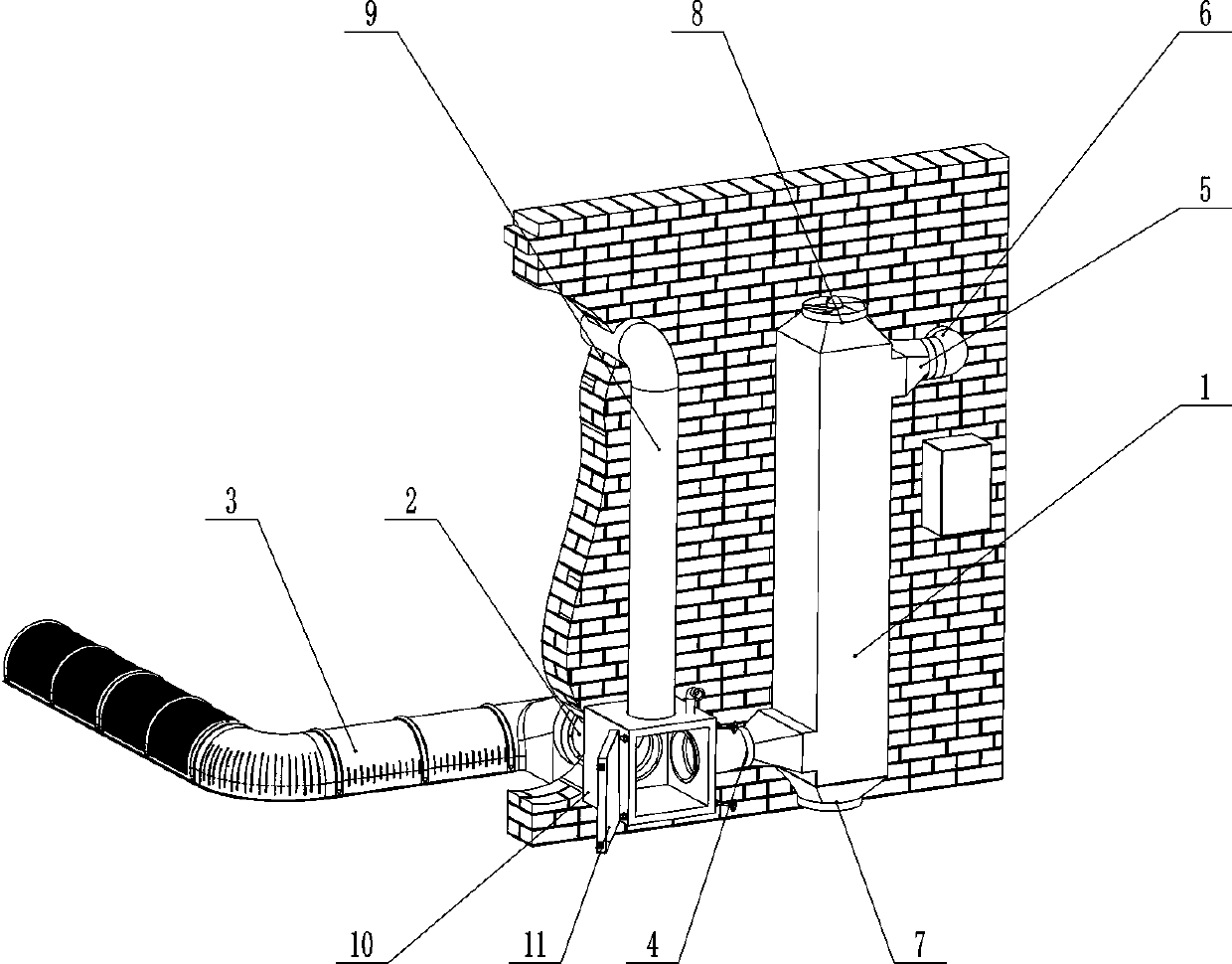

[0055] Such as figure 2 As shown, the difference between this embodiment and Embodiments 1 and 2 is that the internal ventilation pipe network of the granary also includes a thermal insulation circulation pipe 9 and a thermal insulation closed box 10, and the thermal insulation closed box 10 has three interfaces and an opening and closing The airtight box body of the box door 11, the outlet of the ventilator, the inlet of the heat preservation circulation pipe 9 and the hot air inlet 4 of the heat exchanger 1 are respectively sealed and connected to the three interfaces of the heat preservation airtight box 10 , wherein the two interfaces connected with the air inlet of the thermal insulation circulation pipe and the hot air inlet of the heat exchanger are equipped with sealing plugs, and the outlet of the thermal insulation circulation pipe 9 is used to communicate with the inside of the granary.

[0056] The structure added in this embodiment is to utilize the grain cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com