Layered gradient-structure tungsten-based composite material and preparation method thereof

A gradient structure, composite material technology, applied in metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of poor toughness of tungsten materials, and achieve the effects of excellent toughness, good comprehensive performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

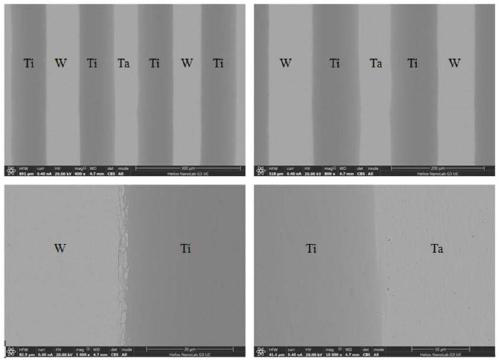

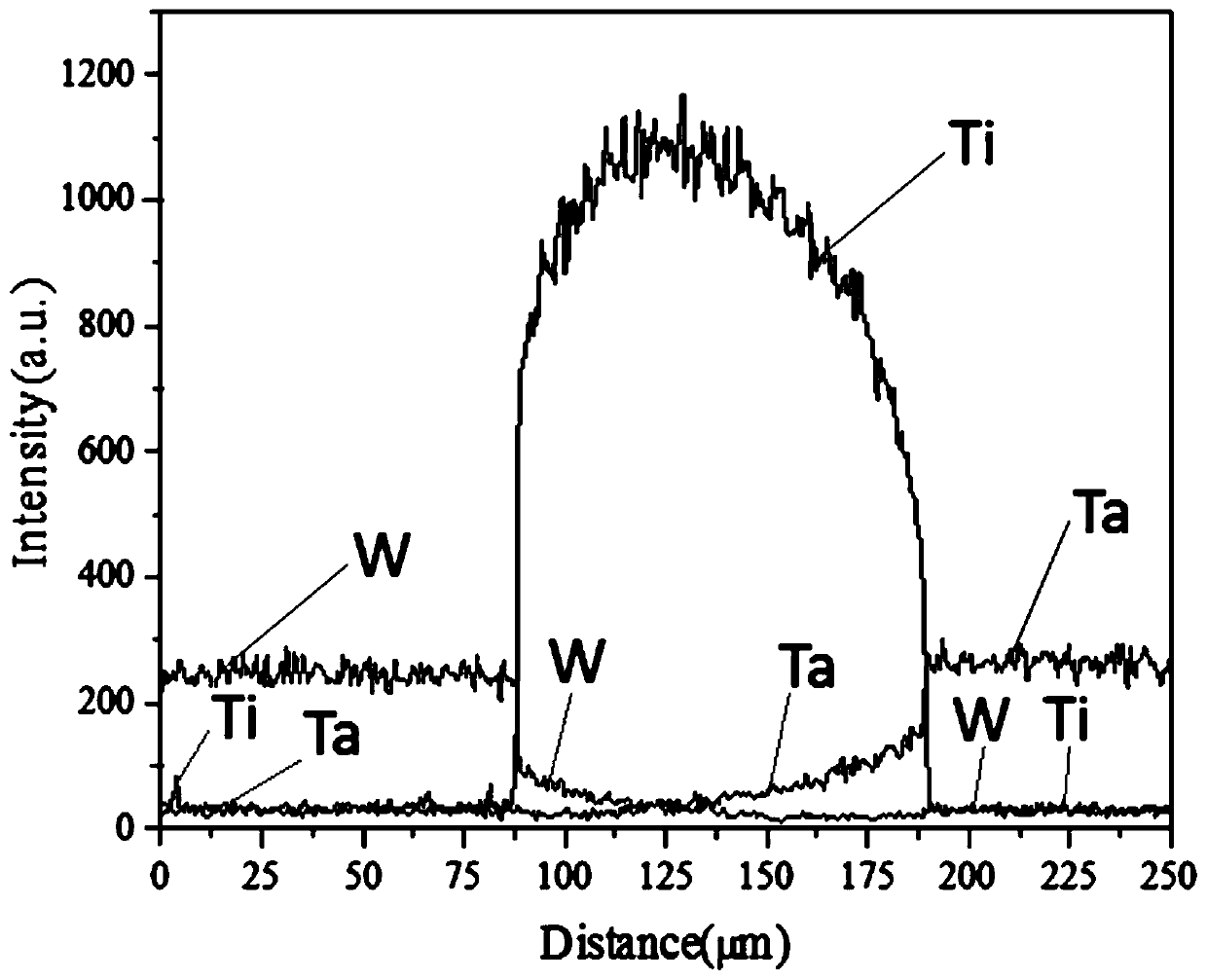

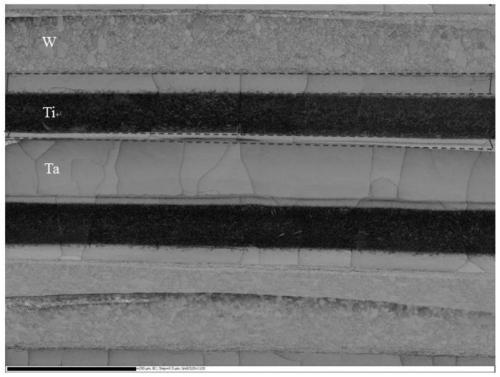

[0054] A tungsten-based composite material with a layered gradient structure provided in this embodiment includes five repeating units, each repeating unit includes a tungsten layer, a titanium layer, a tantalum layer, a titanium layer, and a tungsten layer arranged in sequence, and two adjacent The repeating unit shares a tungsten layer; the tungsten layer, titanium layer and tantalum layer are all made of rolled metal foil.

[0055] The thicknesses of the tungsten foil, titanium foil and tantalum foil in this embodiment are all 100 μm.

[0056] The layered gradient structure tungsten-based composite material described in this example is prepared by the following method:

[0057]Surface treatment: Cut titanium foil and tantalum foil into discs with a diameter of 20 mm, place them in absolute ethanol for 10 minutes, remove dust and other impurities attached to the surface, dry them in vacuum and store them in a sealed container; Cut into discs with a diameter of 20mm by wire ...

Embodiment 2

[0071] A tungsten-based composite material with a layered gradient structure provided in this embodiment includes five repeating units, each repeating unit includes a tungsten layer, a titanium layer, a tantalum layer, a titanium layer, and a tungsten layer arranged in sequence, and two adjacent The repeating unit shares a tungsten layer; the tungsten layer, titanium layer and tantalum layer are all made of rolled metal foil.

[0072] The thicknesses of the tungsten foil, titanium foil and tantalum foil in this embodiment are all 100 μm.

[0073] The layered gradient structure tungsten-based composite material described in this example is prepared by the following method:

[0074] Surface treatment: Cut titanium foil and tantalum foil into discs with a diameter of 20 mm, place them in absolute ethanol for 10 minutes, remove dust and other impurities attached to the surface, dry them in vacuum and store them in a sealed container; Cut into discs with a diameter of 20mm by wire...

Embodiment 3

[0088] The main difference between this embodiment and the first embodiment lies in the specific parameters of spark plasma sintering.

[0089] In this embodiment, the spark plasma sintering process includes three stages:

[0090] The first stage is the stage of temperature rise and pressure increase. The stepwise temperature rise method is adopted. First, the temperature rises from room temperature to 600°C at a heating rate of 95°C / min, and then from 600°C to 1200°C at a heating rate of 100°C / min. At the same time, a constant rate of pressure increase is adopted, and the pressure is set at 3.5KN at room temperature, and the pressure reaches 9.5KN when the temperature reaches 1200°C;

[0091] The second stage is the heat preservation and constant pressure stage, and the time is 10 minutes;

[0092] The third stage is the temperature and pressure drop stage, from 1200°C to 600°C, the temperature drop rate is 30°C / min, and at the same time, the pressure is reduced at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com